49 © STULZ SpA . – all rights reserved EN/39B/06.2018

SAL

Opening the refrigerant connectors

Open the refrigerant taps of the external unit following this order:

• IN tap of motor-condensing unit

• OUT tap of motor-condensing unit

Filling with refrigerant (when necessary)

If distance covered by refrigerant lines is more than 5 m, refrigerant must be added. This operation

must be done after completing installation and start-up of the unit. While compressor is running,

connect the charge cylinder to the low pressure (suction) gas side of compressor and fill with the

right quantity as per table 2.

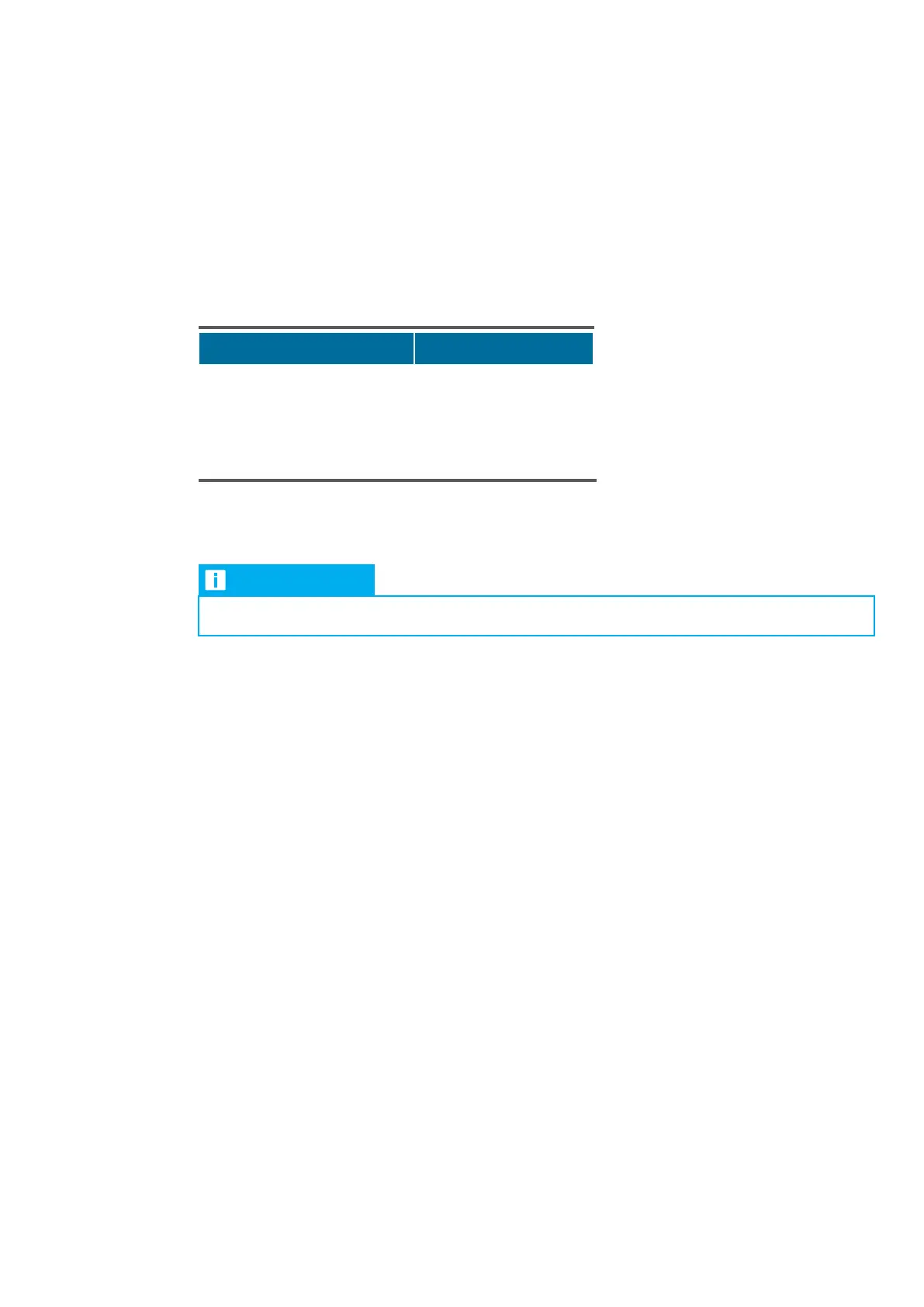

Gas/liquid pipe ext. diameter [mm] R407C additional charge [g]

10; 12 2 d

16 4 d

18 5 ,5 d

22 8,5 d

28 14,5 d

TABLE 2: Additional charge of R407C refrigerant for piping distance beyond 5m (maximum 30 m).

Values applying with condensation T = 50°C

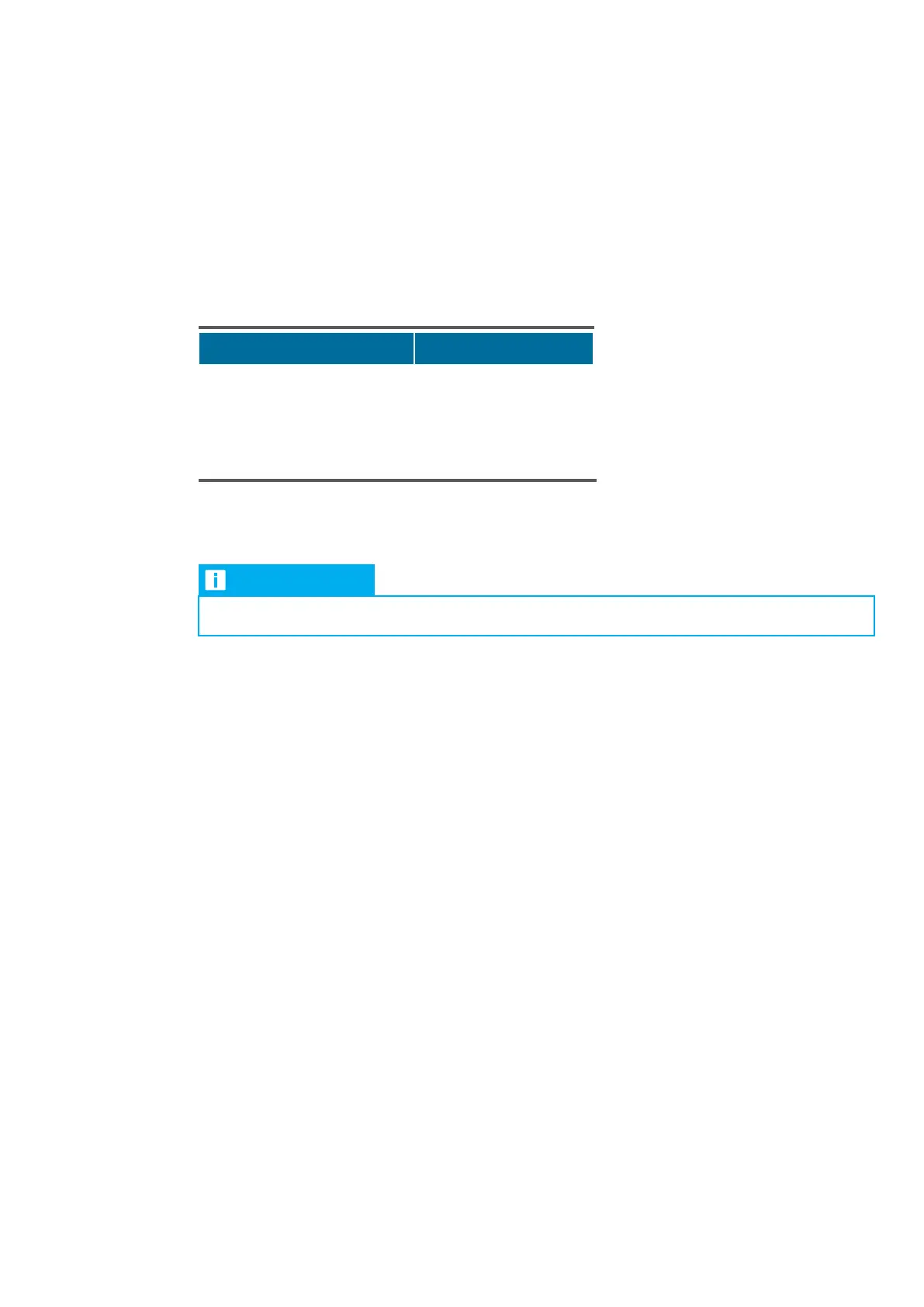

INFORMATION

In this table d = distance (measured in meter)

Make sure, while the system is in standard operation, that the superheating complies with following

values in the next table.

Internal temperature [°C]

25 28

Internal relative humidity

% 40 40

Compressor superheating [°C]

8 12

TABLE 3: R407CSuperheating table.

Oil charge (when necessary)

The compressor is supplied with an initial oil charge. The standard oil charge for the use of the

refrigerants R407C and R134a is a polyester (POE) lubricant Copeland 3MA (32 cSt). In the field,

the oil level could be topped up with ICI Emkarate RL 32 F or Mobil EAL Arctic 22 CC, if 3MA is not

available.

Rotary compressor with R407C is supplied with ester oil VG74.

Reciprocating compressor with R407C is supplied with polyester lubricant.

Loading...

Loading...