Section 2

DESCRIPTION

9

Fluid flows from the bottom of the receiver/sump to

the thermal valve. The thermal valve is fully open

when the fluid temperature is below 170

_

F(77

_

C).

The fluid passes through the thermal valve, themain

filter and directly to the compressor unit where it lu-

bricates, cools and seals the rotors and the com-

pression chamber.

As the discharge temperature rises above 170

_

F

(77

_

C), due to the heat of compression, the thermal

valve begins to close and a portion of the fluid then

flows through the cooler. From the cooler the fluid

flows to the main filter and then on to the compres-

sor unit.

A portion of the fluid flowing to the compressor is

routed to the anti--friction bearings which support

the rotors inside the compressor unit. Prior to enter-

ing the compressor unit, this fluid is taken through

the fluid filter, thus assuring properly filtered lubri-

cant for bearing supply.

The fluid filter has a replacement element and an in-

tegral pressure bypass valve.A gauge on the instru-

ment panel shows red when the filter needs servic-

ing. This gauge has a pressure setting lower than

that of the bypass valve. The gauge should be

checked with compressor running at full system

pressure.

Water--cooled versions of the compressor have a

water--flow regulating valve (not shown) whichoper-

ates to conserve water during periods of varying

load on the compressor. This same valve automati-

cally shuts off the water supply when the compres-

sor is shut down. In addition, water--cooled models

have a water pressure switch to prevent operation

with inadequate water pressure.

2.5 COMPRESSOR DISCHARGE SYSTEM, FUNC-

TIONAL DESCRIPTION

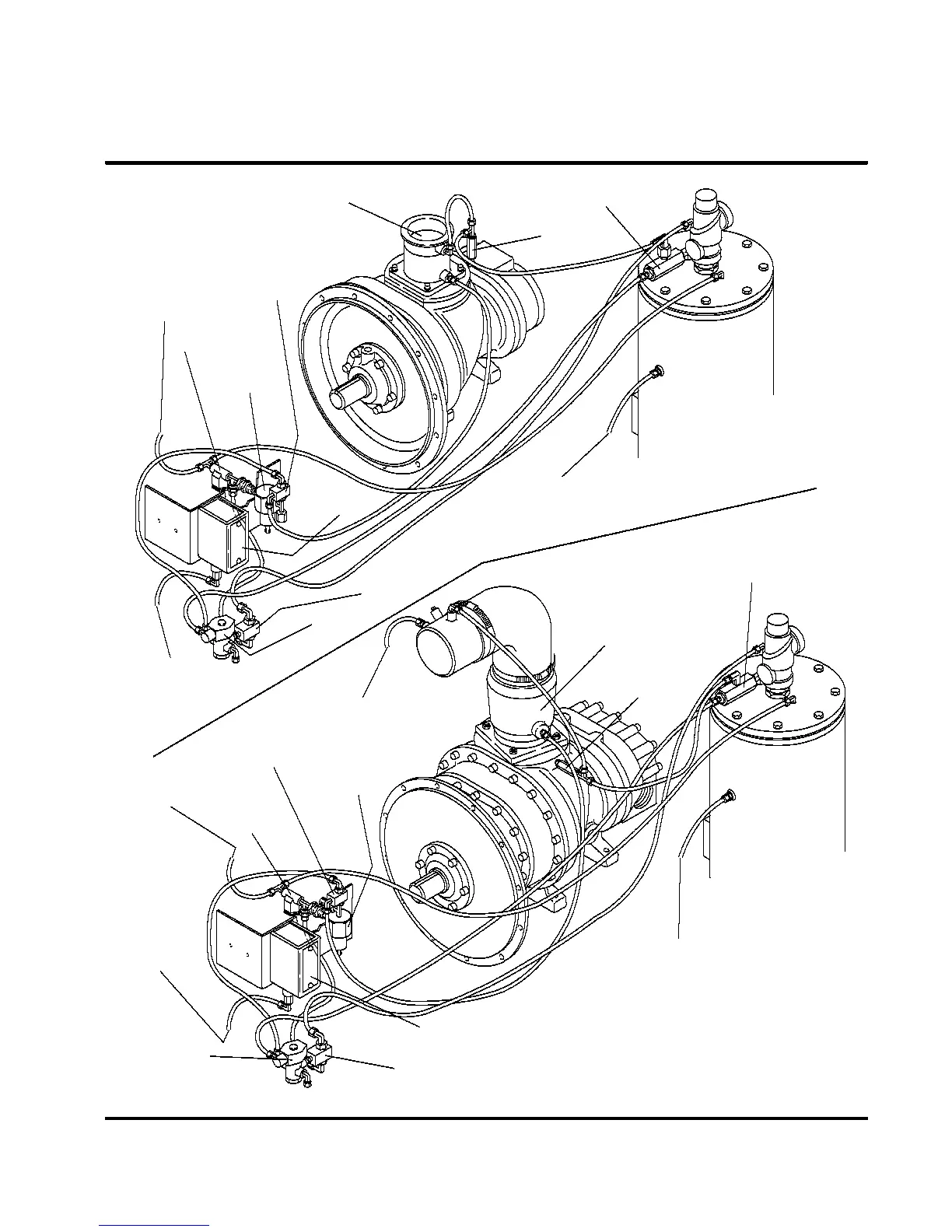

Refer t o F igur es 2 -- 3A and 2 -- 3B. T he c ompr es s or

unit discharges the compressed air/fluid mixture

into the combination receiver/sump.

The receiver has three basic functions:

1. It acts as a primary fluid separator.

2. Serves as the compressor fluid sump.

3. Houses the final fluid separator.

The compressed air/fluid mixture enters the receiv-

er and is directed against the internal baffle. The

direction of movement is changed and its velocity

significantly reduced, thus causing large droplets of

fluid to form and fall to the bottom of the receiver/

sump. The fractional percentage of fluid remaining

in the compressed air collects on the surface of the

separator element as the compressed air flows

through the separator. A return line (or scavenge

tube) leads from the bottom of the separator ele-

ment to the inlet region of the compressor unit. Fluid

collecting on the bottom of the separator is returned

to the compressor by a pressure differential be-

tween the receiver and the compressor inlet. A visu-

al sight glass is located on the return line to observe

this fluid flow. There is also an orifice in this return

line (protected by a strainer) to assure proper flow.

This separation will reduce the fluid carry--over to

less than 2 ppm (parts per million). A gauge, located

on the instrument panel, shows red if abnormal

pressure drop through the separator develops. At

this time, separator element replacement is neces-

sary. This gauge must be checked with the com-

pressor running fully loaded.

A minimum pressure/check valve, located down-

stream from the separator, assures a minimum re-

ceiver pressure of 55 psig (3.8 bar) during loaded

conditions. This pressure is necessary for proper

air/fluid separation and proper fluid circulation.

A terminal check valve is incorporated into the mini-

mum pressure/check valve to prevent compressed

air in the service line from bleeding back into the re-

ceiver on shutdown and during operation of the

compressor in an unloaded condition.

A pressure relief valve (located on the wet side of

the separator) isset to open if thesump pressureex-

ceeds the sump tank rating. A temperature switch

will shut down the compressor if the discharge tem-

perature reaches 235

_

F(113

_

C).

WARNING

!

DO NOT remove caps, plugs, and/or other com-

ponents when compressor is running or pressur-

ized.

Stop compressor and relieve all internal pressure

before doing so.

Fluid is added to the sump via a capped fluid filler

opening, placed low on the tank to preventoverfilling

of the sump. A sight glass enables the operator to

visually monitor the sump fluid level.

2.6 CONTROL SYSTEM, FUNCTIONAL DE-

SCRIPTION- STANDARD ELECTRO-MECHANI-

CAL

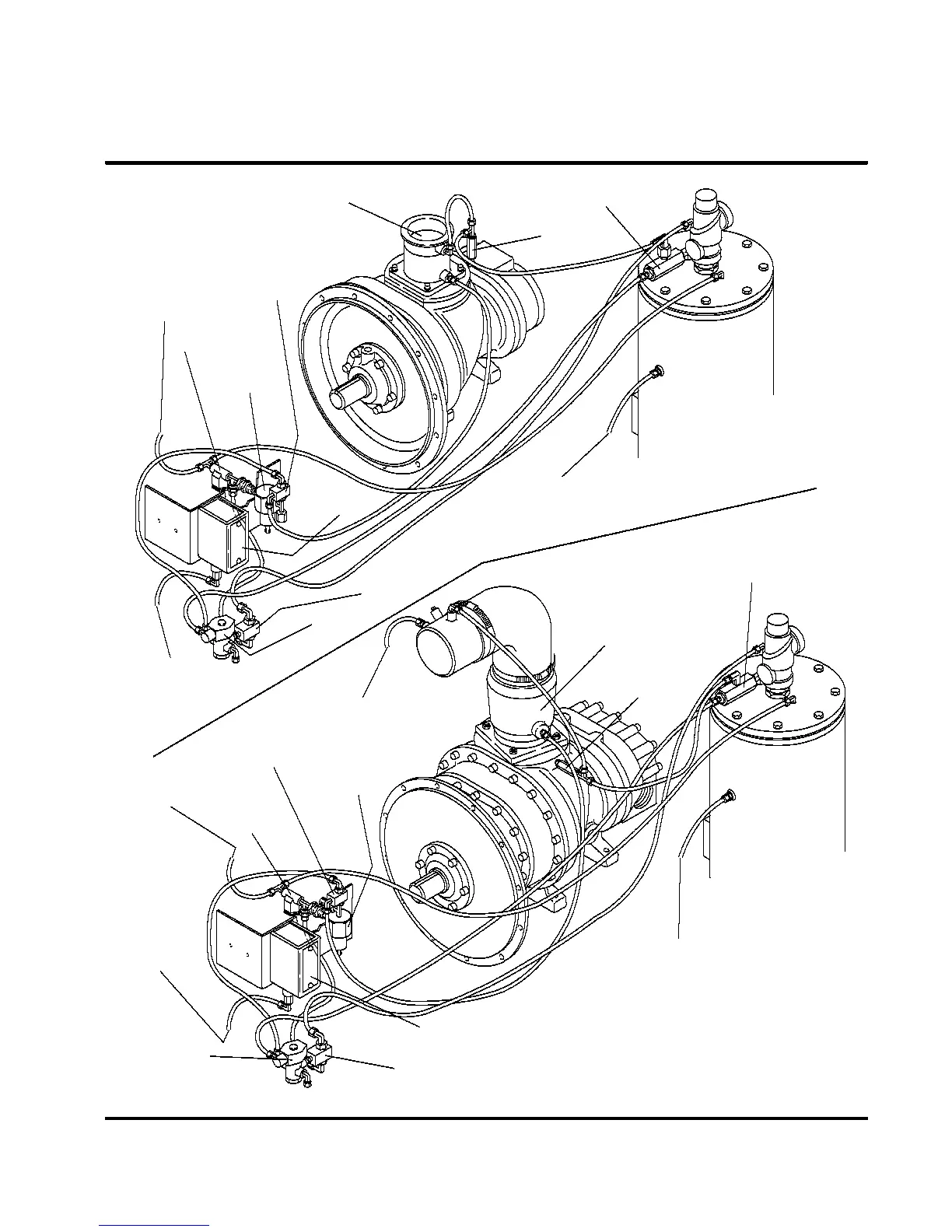

Refer t o F igur e 2 -- 4. T he pur pos e of t he c ompr es s or

Control System is to regulate the compressor air in-

take to match the amount of compressed air being

used. At approximately 10 psig (0.7 bar) air line

over--pressure,the controlsystem willautomatically

blow down the compressor and greatly reduce the

unload power consumption. The Control System

consists of an

inlet valve

, (located on the compres-

sor air inlet),

blowdown valve

,

solenoid valve

,

pressure switch

, and a

pressure regulator

.The

functional descriptions of the Control System are

given below in four distinct phases of compressor

operation. The following guidelines apply to all

LS--10 Series compressors. For explanatory pur-

poses this description will apply to a compressor

with an operating pressure range of 115 to 125 psig

(7.9 to 8.6 bar). A compressor with any other pres-

sure range would operate in the same manner ex-

Loading...

Loading...