Section 2

DESCRIPTION

11

cepting stated pressures.

START - 0 TO 50 PSIG (0 TO 3.5 BAR)

When the compressor START button is depressed,

the sump pressure will quickly rise from 0 to 50 psig

(0 to 3.5 bar). During this period both the pressure

regulator and the solenoid valve areclosed, the inlet

valve is fully open due to inlet air flow, and the com-

pressor pumps at full rated capacity. The risingcom-

pressor air pressure is isolated from the service line

in this phase by the minimum pressure valve, set at

approximately 50 psig (3.5 bar).

NORMAL OPERATING MODE - 50 TO 115 PSIG

(3.5 TO 7.9 BAR )

When the pressure air rises above 50 psig (3.5 bar),

the minimum pressure/check valveopensanddeliv-

ers compressed air to the service line. From this

point on, the line air pressure is continually moni-

tored by a line pressure gauge and a pressure

switch usually set at 125 psig (8.6 bar). The pres-

sure regulator and the solenoid valve remain closed

during this phase. The inlet valve remains fully open

for maximum capacity.

MODULATING MODE - 115 TO 125 PSIG (7.9 TO

8.6 BAR)

If less than the rated capacity of compressed air is

being used, the service line pressure will rise above

115 psig (7.9 bar). The pressure regulator valve

gradually opens, applying air pressure through the

control line to the inlet valve piston. This causes the

inlet valve to partially close reducing the amount of

air entering the compressor until it matches the

amount of air being used. The control system func-

tions continually in this manner, between the limits

of 115 to 125 psig (7.9 to 8.6 bar), in response to

varying demands from the service line.

The pressure regulator has an orifice which vents a

small amount of air to the atmosphere when the

pressure regulator controls the inlet valve. The ori-

fice also bleeds any accumulated moisture from the

control lines.

UNLOAD - IN EXCESS OF 125 PSIG (8.6 BAR)

LINE PRESSURE

When no air is being used,the service line pressure

rises to the setting (cut--out pressure) of the pres-

sure switch. the pressure switch opens, interrupting

the electrical power to the solenoid valve. At this

time, the solenoid valve allows dry sump tank air

pressure or service air pressure through a shuttle

valve to be applied directly to the inlet valve piston

and keep it closed. Simultaneously, the solenoid

valve sends a pneumatic signal to the blowdown

valve. The blowdown valve opens the sump to the

compressor intake reducing the sump pressure to

approximately 25 to 27 psig (1.7to 1.9 bar). The

check valve in the air service line pressure prevents

line pressure from returning to the sump.

Whenthe linepressure drops to thelowsetting(cut--

in pressure) of the pressure switch (usually 115 psig

[7.9 bar]), the pressure switch closes, re--energizing

the 3--way solenoid valve and allowing the blow-

down valve to close. The re--energized solenoid

valve again prevents pressure from reaching the in-

let valve. The inlet valve is fully open and the com-

pressor delivers full rated capacity. Should the pres-

sure begin to rise,the pressureregulator willresume

its normal function as previously described.

To accommodate varied periods of time when there

are not any air requirements, “Dual--Control” is uti-

lized. This feature allows you to set the compressor

in an automatic position whereby the compressor

will shut down when no compressed air requirement

is present and restart as compressed air is needed.

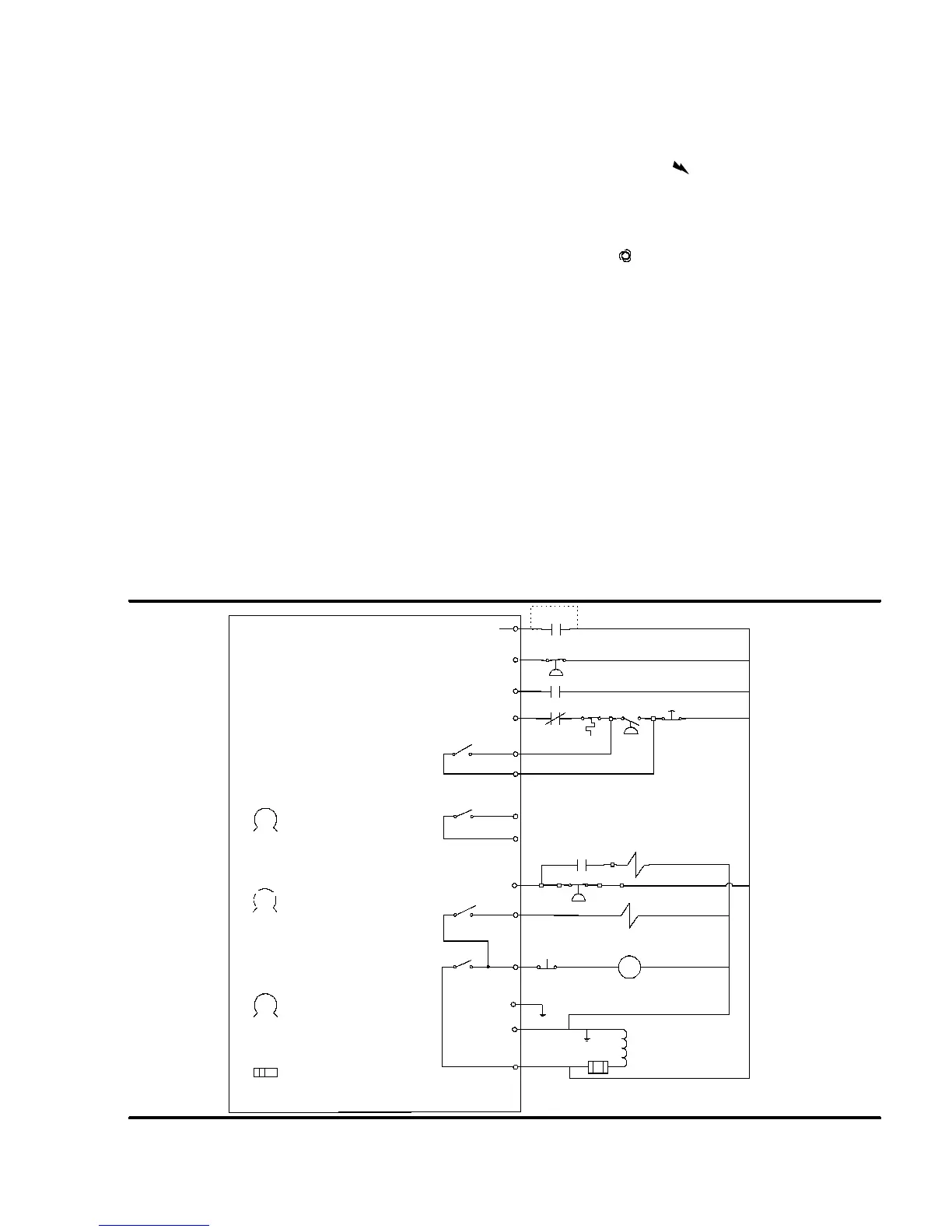

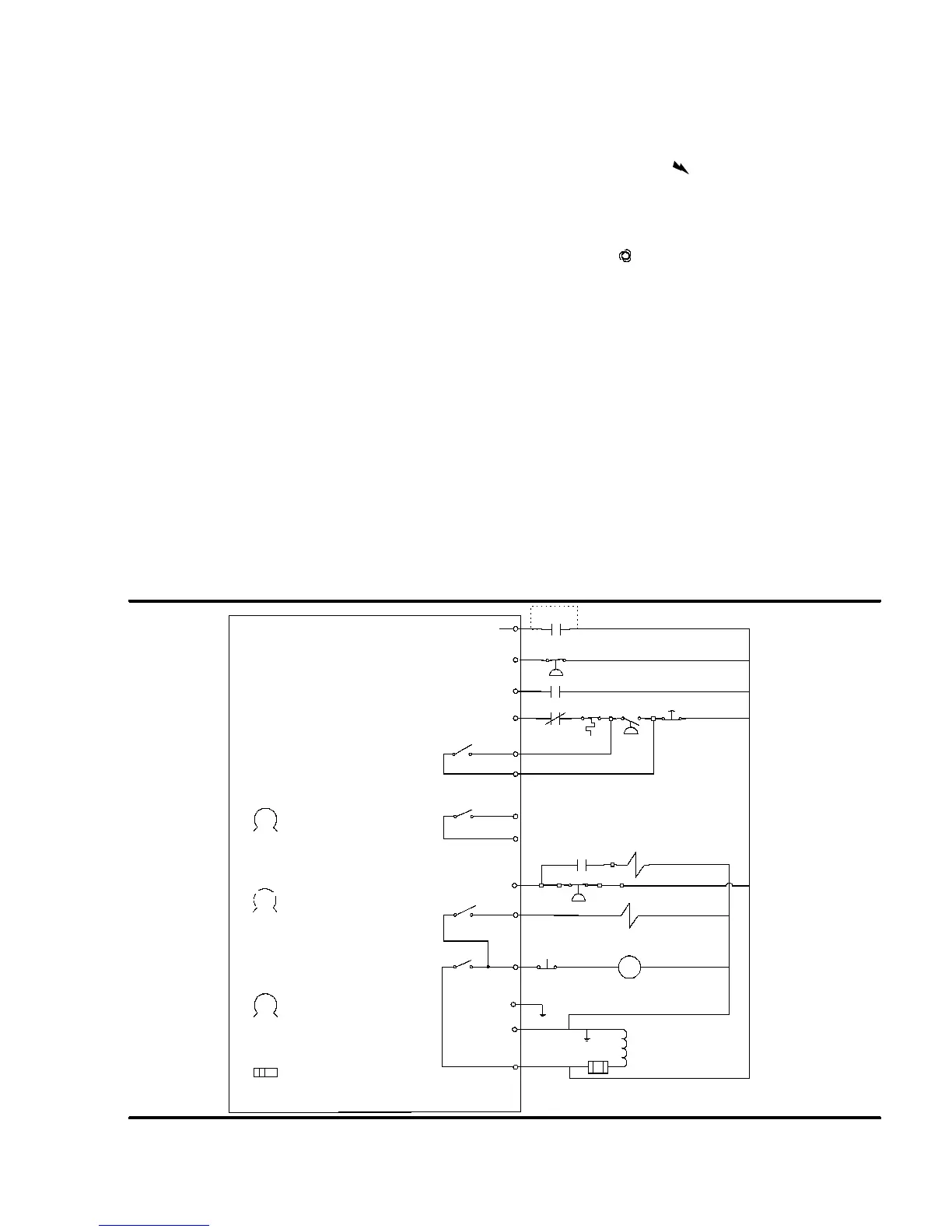

2.7 CONTROL SYSTEM, FUNCTIONAL DE-

SCRIPTION- SUPERVISOR II

Refer t o F igur e 2 -- 4. T he pur pos e of t he c ompr es s or

Control System is to regulatethe amount of air being

compressed to match theamount of compressed air

beingused.TheCapacity control system consists of

a

solenoid valve

,

regulator valve

and an

inlet

valve

. The functional description of the Control Sys-

tem is described below in four distinct phases of op-

eration. The following description text applies to all

LS--10 Series compressors with optional Supervisor

II. For explanatory purposes, this description will ap-

ply to a compressor with an operating range of 100

to 110 psig (6.9 to 7.6 bar). A compressor with any

other pressure range would operate in the same

manner except stated pressures.

START MODE - 0 TO 50 PSIG (0 TO 3.5 BAR)

When the compressor

“I” (START)

pad is de-

pressed, the sump pressure will quickly rise from 0

to 50 psig (0 -- 3.4 bar). The compressor initially

starts unloaded, then switches to full load when full

rpm has been achieved. During this period, both the

pressure regulator and the solenoid valve are

closed, the inlet valve is fully open and the compres-

sor pumps at fullrated capacity. The rising compres-

sor air pressure is isolated from the service line in

this phase by the minimum pressure valve set at

approximately 50 psig (3.4 bar).

FULL LOAD MODE - 50 TO 100 PSIG (3.4 TO 6.9

BAR)

When the compressed air pressure rises above 50

psig (3.4 bar), the minimum pressure valve opens

allowing compressed air to flow into the service line.

From this point on, the lineair pressure is continually

monitored by the Supervisor. The pressure regula-

tor and the solenoid valve remain closed during this

phase. The inlet valve is in the fully open position as

long as the compressor is running at 100 psig ( 6.9

bar) or below.

MODULATING MODE -- 100 TO 110 PSIG (6.9 TO

7.6 BAR)

If less than the rated capacity of compressed air is

being used, the service line pressure will rise above

100 psig (6.9 bar). The pressure regulator valve

gradually opens, directing air pressure to the inlet

Loading...

Loading...