2: Description ShopTek™ ST4, ST5, ST7, ST11, ST15 Three-phase 60 Hz User Manual

88292018-236 R00

14 Subject to EAR, ECCN EAR99 and related export control restrictions.

2.3 Compressor cooling and

lubrication system—functional

description

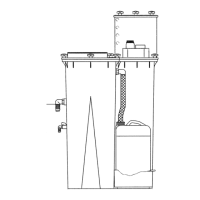

Refer to Figure 2-3 and Figure 2-4. The cooling and lubri-

cation system consists of a fan, fan motor, aftercooler

(

ST11/ST15 only) / fluid cooler, full flow fluid filter, thermal

valve, interconnecting hoses and separator tube.

The pressure in the separator tube starts the fluid flow by

for

cing the fluid from the high pressure area of the tube to

an area of lower pressure in the compressor unit. Fluid

flows from the bottom of the separator/tube to the thermal

valve that is fully open when the fluid temperature is

below 185°F (85°C) [195°F (91°C) for pressures rated

above 150 psig]. The fluid passes through the thermal

valve, the

fluid filter, and directly to the compressor where

it lubricates, cools and seals the rotors, and the compres-

sion chamber.

As the discharge temperature rises above 185°F (85°C)

[19

5°F (91°C) for pressures rated above 150 psig], due

to

the heat of compression, the thermal valve begins to

adjust and a portion of the fluid then flows through the

cooler. From the cooler the fluid flows to the fluid filter

and on to the compressor. A portion of the fluid flow to

the compressor is routed to the anti-friction bearings

which support the compressor rotors.

The fluid filter must be replaced. Refer to Section 3.4:

Lubrication change recommendations

and fluid filter and

separator maintenance on p

age 22.

2.4 Compressor discharge system—

functional description

Refer to Figure 2-3 and Figure 2-4. The compressor dis-

charges the compressed air/fluid mixtur

e into the separa-

tor/tube. The separator/tube has three basic functions:

• It acts as a primary fluid separator.

•

Serves as the compressor fluid sump.

• Houses the final fluid separator.

The compressed air/fluid mixture enters the separator/

tube

and flows through an internal baffle system that

changes the flow’s direction and velocity, which causes

most of the fluid to fall to the bottom of the separator

tube. A small amount of fluid remaining in the com-

pressed air collects on the surface of the separator ele-

ment as the air flows through the separator.

A return line (or scavenge tube) leads from the dry side of

the

separator tube to the medium pressure region. Scav-

enged fluid is returned by a pressure differential between

the sep

arator tube and compressor.

The separator system reduces the fluid car

ry-over to less

than 2 ppm at nominal rated pressures.

The controller will shut down the

compressor if the dis-

charge temperature reaches 235°F (113°C).

A minimum pressure/check valve loc

ated downstream

from the separator maintains the separator tube pressure

at 50 psig (3.4 bar) during load conditions. This pressure

leve

l is necessary for proper air/fluid separation and suffi-

cient fluid circulation.

A terminal check valve is a sub-component of the mini-

mum pressure/check valve that prevents compressed air

in th

e service line from back-flowing into the separator

tube on shutdown or when the compressor is operating in

an unload condition. Also, a pressure relief valve on the

compressor’s wet side opens if the separator tube pres-

sure exceeds its rating.

Add fluid to the separator tube through the capped fluid

fill

port. There is also a sight glass that enables the user

to check the separator tube fluid level. See Section 4.5:

Fluid level check on p

age 37.

WARNING

Stop the compressor and relieve all internal

pressure before removing caps, plugs, and/or

other components when the compressor is run-

ning or pressurized.

Loading...

Loading...