ShopTek™ ST4, ST5, ST7, ST11, ST15 Three-phase 60 Hz User Manual 4: Installation

88292018-236 R00

Subject to EAR, ECCN EAR99 and related export control restrictions. 37

4.3.1 Pipe sizing

Pipes should be sized as a minimum to match the dimen-

sions of the compressor’s discharge co

nnection. All piping

and fittings should be rated for the discharge pressure.

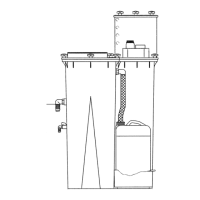

4.3.2 Auxiliary receiver tank

An auxiliary receiver tank should be installed in systems

where large demand fluctuations will occur.

4.3.3 Isolation valves

Install isolation valves where isolation of the compressor

from the service lines is required. These valves should

have drip legs that drain at an angle downward from the

base. A vent to the piping should be installed down-

stream of the compressor outlet connection.

When two compressors are installed to operate in parallel

with a comm

on receiver tank, an isolation valve and drain

trap for each compressor should be installed before the

common separator/sump.

4.3.4 Fluid containment

Compressors have a fluid containment pan to collect fluid

leaks or spills. The pan has a drain located on the front

side of the machine.

4.4 Belt check

Tension of drive belts should be checked upon installa-

tion and after ½ to 2 hours of run time. This is essential to

pr

oper performance of the compressor unit as well as to

ensure long belt life. In addition, belt tension should be

checked every 2000 hours and adjusted if necessary.

Refer to Section 6.8: Belt maintenance

on page 45 for

detailed instructions.

4.5 Fluid level check

The compressor is shipped fully charged with the proper

amount of fluid. However, it is necessary to check the fluid

level at the time of installation and during compressor oper-

ation. Check the fluid level by looking at the sight glass on

the sep

arator tube when the compressor is in the SHUT

DOWN MODE (fluid level may not be visible when operat-

ing). In this condition the sight glass should be completely

full. Add

fluid if the level is visible or if no fluid is visible at all.

4.6 Electrical preparation

Interior electrical wiring is installed at the factory.

Required customer wiring should be done by a qualified

electrician in compliance with OSHA, National Electric

Code and/or any applicable local electrical codes apply-

ing to isolation switches, fused disconnect

s, etc. Sullair

provides a wiring diagram for use by the installer. An

electrical check should be made to ensure that the first

start-up will be successful. The compressor and drive

should be properly grounded/earthed in accordance with

applicable codes, regulations, and requirements.

Feeder cables should be sized by the customer/electrical

con

tractor to ensure that the circuit is balanced and not

overloaded by other electrical equipment. The length of

wiring from a suitable electrical power source is critical

because voltage drops can adversely effect the perfor-

mance of the compressor. Cable sizes may v

ary consid-

erably so the mains terminals will

accept up to 120 mm

2

(4/0 awg) (75 kw) cable.

Feeder cable connections to incoming terminals L1-L2-

L3

should be tight and clean.

The applied voltage must conform to the motor and com-

pressor data plate ratings.

A starter hole is provided for an incoming power connec-

tion. If it is necessary to make a hole

in the control box in

a different location, care should be taken to not allow

metal shavings to enter the starter and other electrical

components within the box. If another hole is used, the

original hole must be blocked off with a sealed plug.

1. Check incoming voltage. The incoming volt-

ag

e must match the compressor’s wire rat-

ing/specifications.

2. Check motor starter and overload heater sizes.

3. Check all electrical connections for tightness.

NOTE

Compressors not equipped with a receiver tank

may need to have their response times adjusted.

Contact Sullair Customer Care for assistance.

WARNING

Energized internal components are a potentially

fatal shock hazard. Disconnect all power before

performing any work on the compressor’s elec-

trical system.

Loading...

Loading...