ShopTek™ ST4, ST5, ST7, ST11, ST15 Three-phase 60 Hz User Manual 2: Description

88292018-236 R00

Subject to EAR, ECCN EAR99 and related export control restrictions. 15

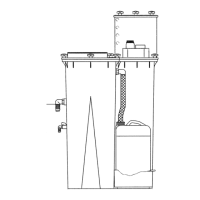

2.5 Control system—functional

description

Refer to Figure 2-5 and Figure 2-6. The compressor con-

trol system regulates its output to match the demand.

This

system consists of a solenoid valve and an inlet

valve that control the compressor’s operational modes.

The following descriptions of operational modes apply to

a compressor whose rated operating pressure is

125 psig (8.6 bar).

Start mode—0 to 50 psig (0 to 3.5 bar)

There is no load on the compressor at startup, the sole-

noid valve is open and the inlet va

lve is closed. When the

compressor (START) pad is pressed, the separator

tube pressure rises from 0 to 50 psig (0 to 3.4 bar). When

it re

aches its full operating speed (maximum rpm), the

compressor switches to the full load mode.

Full load mode—50 to 127 psig (3.4 to 8.8 bar)

When the compressed air pressure rises above 50 psig

(3.4 bar), the minimum pressure valve opens allowing

comp

ressed air to flow into the service line. From this

point on, the Controller continuously monitors the line air

pressure. The solenoid valve remains closed in this

mode. As long as the compressor is running at 127 psig

(8

.8 bar) or lower, the inlet v

alve is fully open.

Unload mode—greater than 127 psig (8.8 bar)

When there is no, or only a small demand, the service

line pressure will rise. The controller de-energizes the

solenoid valve when the pressure exceeds 127 psig

(8

.8 bar) allowing the separator tube air pressure to be

supplied directly

which closes the inlet valve. At the same

time the solenoid valve exhausts the system pressure to

the atmosphere and lowers the separator tube pressure

to approximately 29 psig (2.0 bar). A check valve in the

air

service line prevents air from back-flowing to the sep-

arator tube.

When the pressure drops to the low setting: (cut-in pres-

sure) usually 112 psig (7.7 bar) for high pressure (9 bar)

compres

sors, 137 psig (9.4 bar) for (10 bar) compres-

sors, 161 psig (11.1 bar) for (12 bar) compressors: the

con

troller energizes the solenoid valve and prevents line

pressure from reaching the inlet control valve.

NOTE

Other pressure settings can be selected

depending on compressor application or rating.

Loading...

Loading...