ShopTek™ ST4, ST5, ST7, ST11, ST15 Three-phase 60 Hz User Manual 6: Maintenance

88292018-236 R00

Subject to EAR, ECCN EAR99 and related export control restrictions. 45

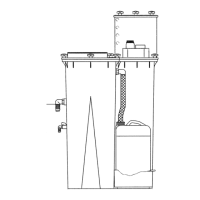

6.7.1 Separator element replacement

Refer to Figure 6-6 and Figure 6-7. Use the following pro-

cedure below to change the separator:

1. Loosen and remove the six (6) hex head

cap

screws (M12 x 45 mm) from the cover

plate.

2. Lift the cover plate from the separator tube.

3. Remove the separator element.

4. Inspect the separator tube for rust, contami-

nation, or damage.

5. Reinsert the separator elements into the

separator tube taking care not to dent the

element against the tank opening.

6. Install a new lubricated O-ring in the O-ring

groove on the underside of the separator/

tube cover.

7. Replace the cover plate, washers and cap-

screws. Torque to 28 ft·lbs. (38 N·m).

8. Clean the return line strainer before restart-

ing the compressor. Refer to Figure 6-1 and

Figure 6-2.

9. Check condition of grounding spring on lid,

ensure it is clean and provides good contact.

6.8 Belt maintenance

The correct drive belt tension is essential to ensure that

full motor power is transmitted to the compressor unit.

The belt tension is achieved by raising the compressor

unit which has the effect of increasing belt tension. Refer

to Figure 6-10 and Figure 6-11.

Belt tension must be re-adjusted ½ to 2 hours after a new

set

of belts are fitted. This will ensure that the belts have

completed their initial stretch. Subsequent to this, belt

tension needs to be checked and adjusted if necessary

every 2000 hours for the duration of the belt life.

There are two recommended methods for checking the

belt

tension. The test methods will be detailed as follows.

6.8.1 Belt tension measurement with

Optikrik tension meter

Refer to Figure 6-8. Follow instructions as follows:

1. Ensure the indicator arm is pushed down

pr

ior to starting.

2. Gently place the meter on the flat side of one

belt at the midpoint between the motor and

compressor unit pulleys.

3. Slowly press on the push pad. Avoid contact-

ing the meter with other fingers as this may

affect the reading.

4. Once a definite click is detected, immediately

release pressure and the indication arm will

remain in the measuring position.

5. Carefully lift the meter without moving indi-

cating arm.

6. Read the measurement at the exact point

where the top surface of the indicator arm

crosses the scale.

7. Rotate the motor pulley through at least one

complete revolution and measure the ten-

sion again, recording the results.

8. Repeat step 7 for a total of 3 measurements.

CAUTION

Relieve all pressure from the separator/sump

tank and all compressor lines.

Figure 6-8: Optikrik belt tension meter

Loading...

Loading...