3: Specifications ShopTek™ ST4, ST5, ST7, ST11, ST15 Three-phase 60 Hz User Manual

88292018-236 R00

22 Subject to EAR, ECCN EAR99 and related export control restrictions.

3.2 Lubrication guide

Refer to Figure 3-1 for the fluid fill port location. Sullair’s

ShopTek series compressors are filled and

tested at the

factory with Sullube

®

lubricant.

3.3 Application guide

Sullair encourages its customers to participate in a fluid

analysis program with the fluid suppliers. In some cases

the analysis results suggest a fluid change interval which

differs from the User Manual. Contact a Sullair represen-

tative for details.

3.4 Lubrication change

recommendations and fluid filter

and separator maintenance

3.5 Installation drawings (ID), piping

& instrumentation diagrams

(P&I), and wiring diagrams (WD)

Printed copies of your installation drawings (ID), piping &

instrumentation diagrams (P&I), and wiring diagrams

(WDs) for your compressor are included in the packet of

printed documentation included with your compressor.

PDFs of these drawings are included on the documenta-

tion CD included with our compressor.

CAUTION

Do not mix different types of lubricants. Mixing

lubricants can cause malfunctions or compres-

sor damage and will void the

compressor’s war-

ranty.

CAUTION

Contamination of compressor fluids with mineral

oil or other fluids can cause foaming, filter plug-

ging, or orifice line obstruction.

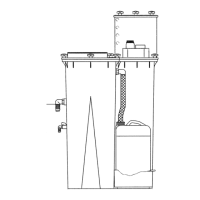

Figure 3-1: Fluid fill location

1. Separator tube 3. Fluid fill port

2. Sight glass 4. To drain

†

†

Disconnect oil line from cooler

NOTE

When performing a fluid change or topping off:

With machine off, fill to the bottom of the fill port.

Sight glass will be completely full.

Mixing, changing or adding other lubricants

with

in the compressor unit may void the air end

warranty.

Lubricant

Fluid

change

Filter

change

Separator

change

Sullube

†

ABC

Key:

A—1 year

B—2,000 hours

C—4,000 hours

†

ST4, ST5, ST7: 1 gallon (4 liters)

ST11, ST15: 1.3 gallons (5 liters)

Loading...

Loading...