19

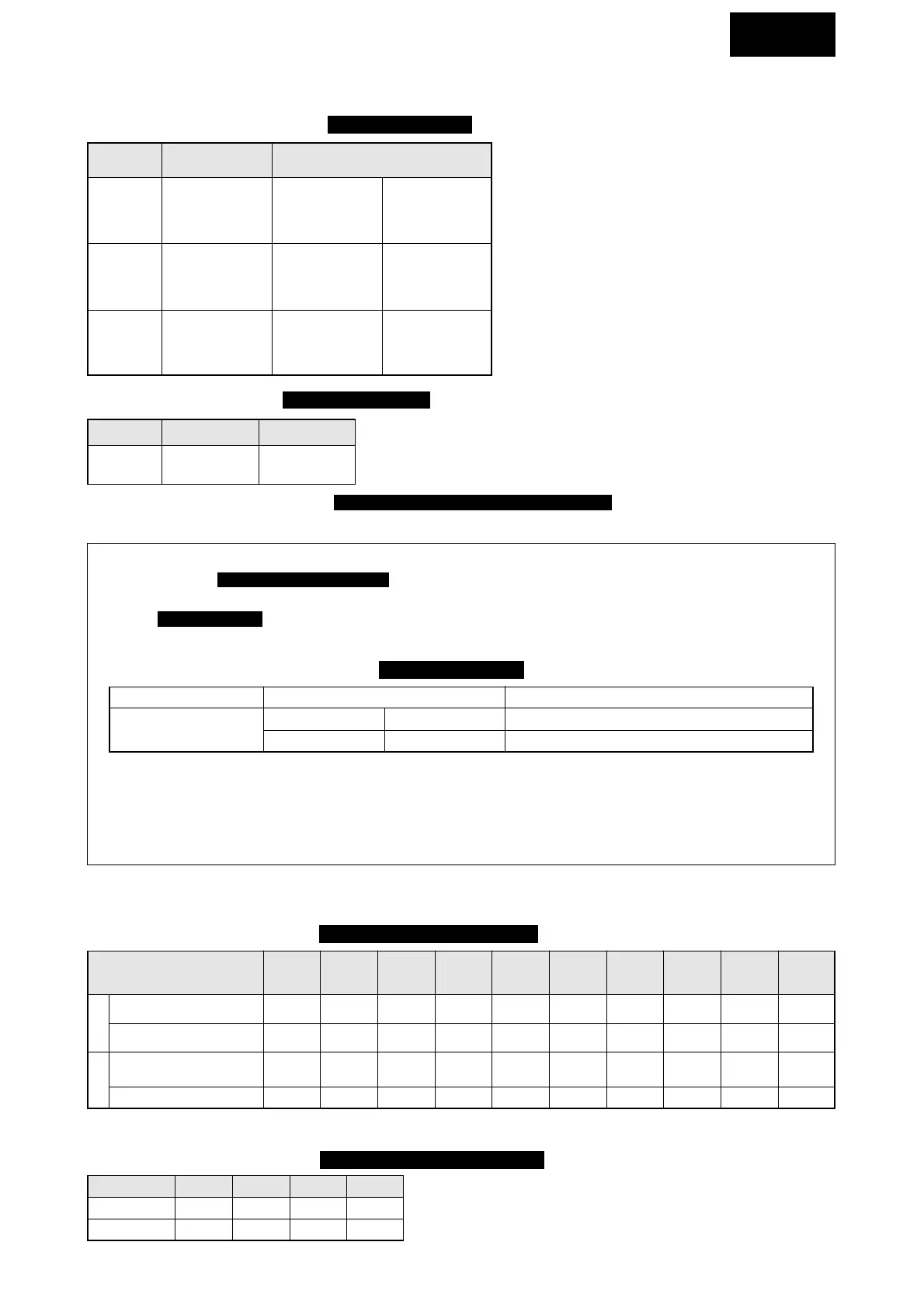

(2) Recommended Lubricants

Be sure to use a lubricant recommended by our company.

Ambient

Tempperature

-10°C – 5°C

0°C– 35°C

30°C – 50°C

Shell Oil

Shell Tellus

S2 M 46, 68

Shell Tellus

S2 M 100

Shell Morlina

S2 B 150

Shell Morlina

S2 B 220

Nuto H 68

Teresso 100, 150

Teresso 220, 320

Exxson Mobil

Mobil DTE 25, 26

(ISO VG46, 68)

Mobil DTE

Oil Heavy

(ISO VG100)

Mobil Vacuoline 528

(ISO VG150)

Mobil Vacuoline

533,537

(ISO VG220, 320)

Table 17 Recommended Lubricating Oil for A Type and B type

Ambient

tempperature

-10°C – 40°C

Idemitsu

Kosan

Daphne Alpha

Drive P150

JX Nippon Oil &

Energy

TD Oil 150

Table 18 Traction oil designated for D Type (ND Series)

1 For operation in winter or at a relativery low ambient temperature, use lubricating oils with lower viscosity.

In the case of forced lubrication models , a plunger pump or trochoid pump may cause cavitation and necessary

amount of oil may not be supplied. In such a case, a burned main body may result.

2 For N02A and M02B with small input capacity in particular, use of lower viscosity oils is recommended.

3 Table 19 shows selection standard for viscosity of lubricating oil.

Min allowable viscosity

Max allowable

viscosity

Above 20mm

2

/s at oil temp, during operation

Viscosity to obtain the oil film needed for transmission of the load

Viscosity that allows Variators to start

Viscosity that allows plunger pumps and trochoid pumps to start

Oil bath lubrication

models

less than 4300mm

2

/s

Forced oil lubrication

models

less than 2200mm

2

/s

Table 19 Selection Standard for Oil Viscosity for A Type and B Type

4 To ensure smooth start, use lubricating oil whose pour point is at least 5-10°C lower than ambient temperature.

5 If ambient temperature varies over a wide range, use lubricating oil whose viscosity remains stable, or lubricating oil

that will satisfy requirments in Notes 3 and 4 in high viscosity index.

6 When units are always used at an ambient temperature other than 0 to 40°C, consult with the factory because

depending on models it may need to change some parts or preheat or cool lubricating oil.

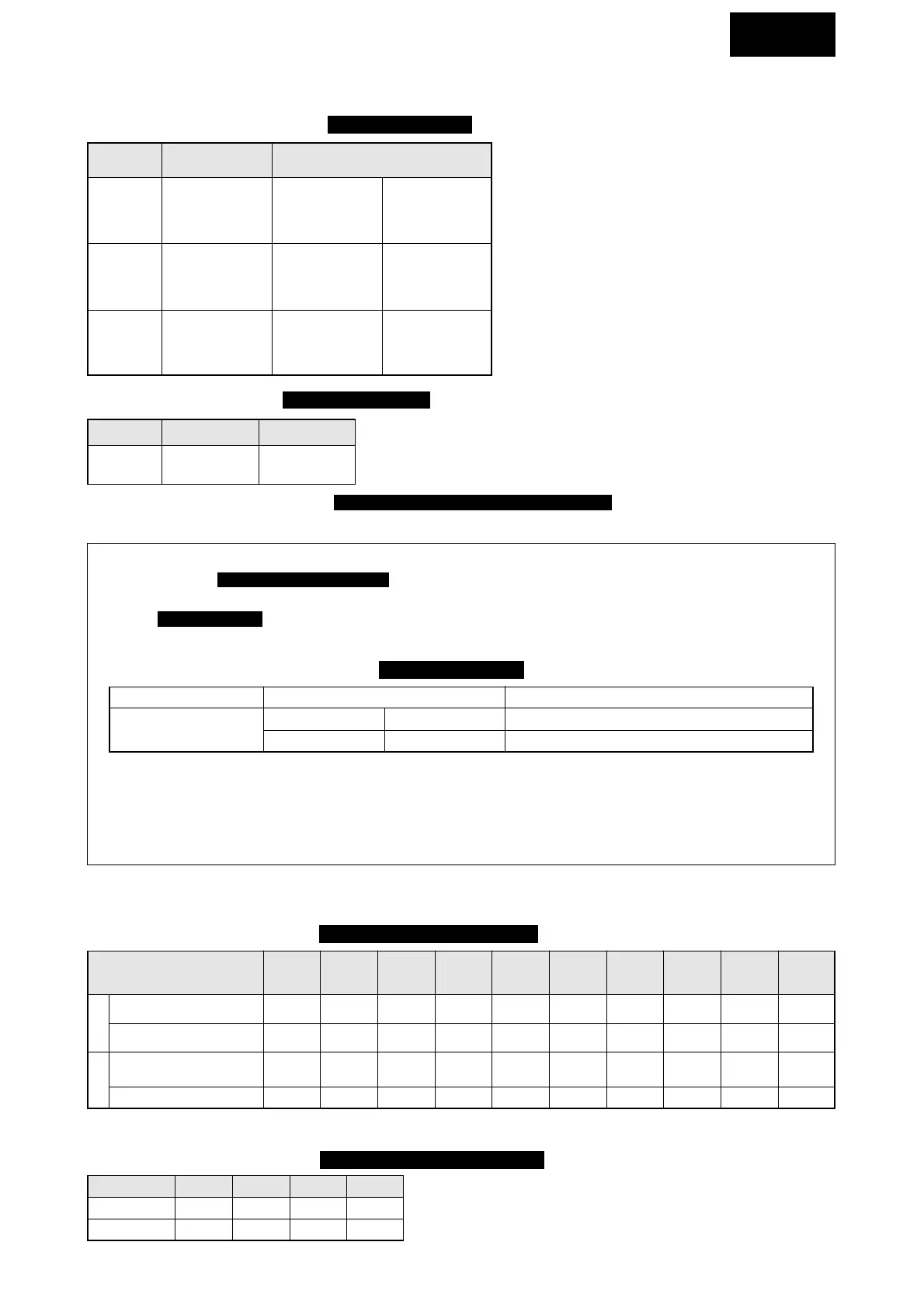

(3) Oil Quantity

Table 20, 21 shows approx. quantity of oil. Be sure to check the oil level through the oil gauge.

Note: Regarding 50A—200A and 50B—150B, amounts in pipe and oil cooling device. Amounts of oil in the oil cooling device : 3.2L for 50A. 75A, 100A,

50B, and 75B, 6.7L for 150A amd 100B, 13.5L for 200A and 150B.

Table 20 Amount of Lubricating Oil (L) for A Type and B Type BEIER Part

BEIER size

Horizontal

Basic model

With a gear reducer

Built-in gear type

Verticlal

Basic model

With a gear reducer

Built-in gear type

N02A

N05A

N1A

0.7

1.1 2.3 5.2 7.5 13 20 38 98 – –

2.6 7.4 15 10 20 24 38 108 – –

1.8 3.7 4.3 11 10 20 56 85 95

1.5 4.1 7.6 6.5 12 13 23 56 85 95

N02B

N05B

N2A

N3A

N1B

N2B

N5A

N8A

N10A

N3B

N5B

N8B 15A 10B 20A 15B

30A

40A

20B

30B

50A

75A

100A

50B

75B

150A 100B 200A 150B

Table 21 Amount of Lubricating Oil (L) for D Type (ND Series) BEIER Part

BEIER size

N05D

Horizontal 1.2

Vertical 2.6

N1D N2D

2.4

5.5

N3D N5D

4.8

13.5

N8D N10D

8.7

19.5

COMMON

Always use correct lubrication oil for D Type (ND Series) BEIER-CYCLO Variator , which requires different lubrication

oil for BEIER part and CYCLO part.

Loading...

Loading...