Installation

Figure 6 Attach Identification Label

2. Arrange the system components so that the gas lines will be protected from stress and

traffic. Observe the minimum bend radius of 180 mm (7") when routing gas lines. Provide

supports where needed.

3. Remove the dust caps from the compressor’s supply and return gas couplings.

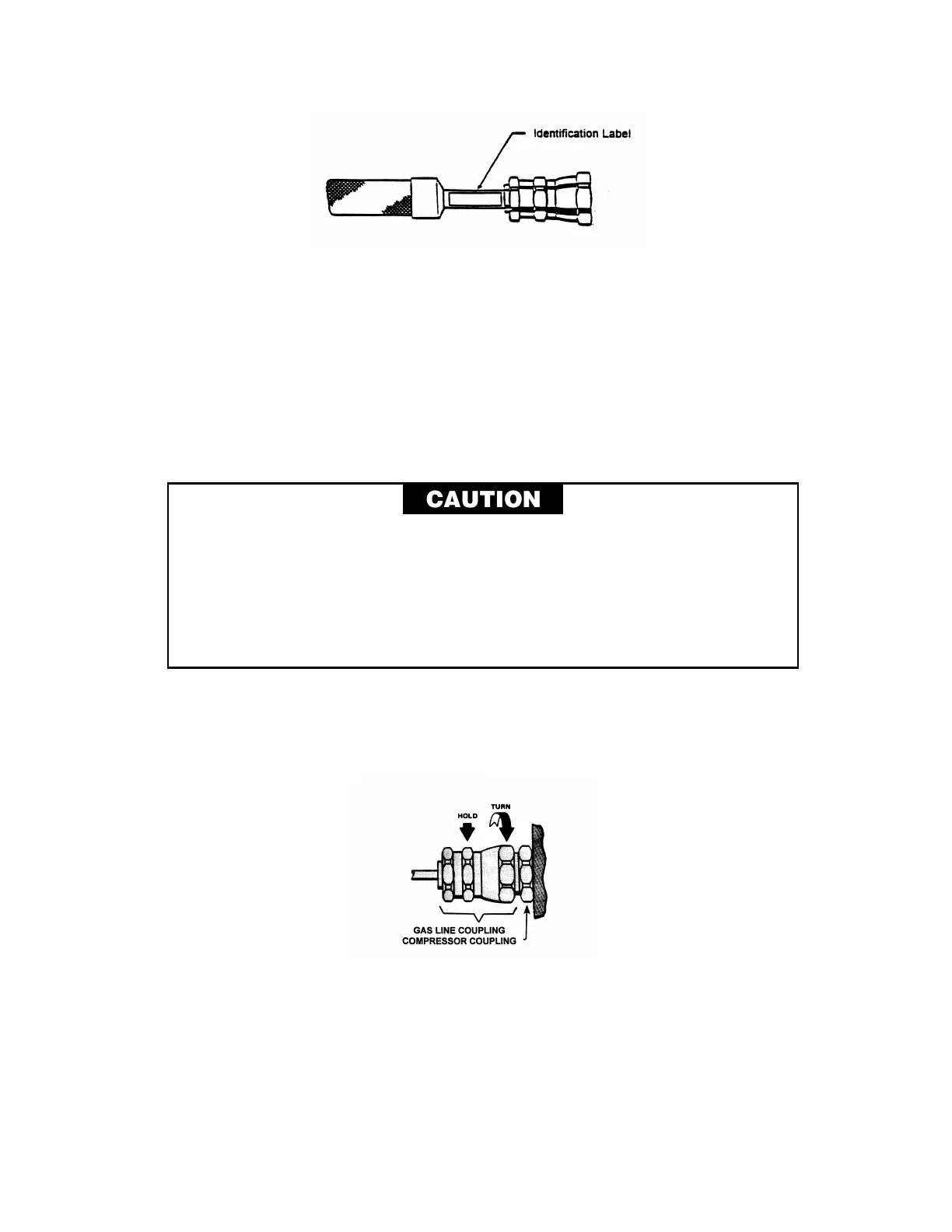

4. Connect the gas lines to the compressor’s high-pressure (supply) and low-pressure (return)

couplings. Use two wrenches to tighten the coupling. Torque all couplings to 47 ± 7 Nm (35

± 5 ft. lbs.) See Figure 7. Tighten each coupling before proceeding to the next one.

AVOID GAS LEAKS. Check the condition of the gasket seal on the male half of

each Aeroquip coupling. Be sure the gasket seal is in place and the sealing

surfaces on both the male and female halves are clean before connecting.

Replace the gasket seal if it is damaged or missing.

Keep the gas line couplings aligned when making or breaking a coupling

connection. Leaks can occur due to the weight of the gas line or due to a sharp

bend near the connection.

NOTE

Retain the dust caps and plugs to re-cover the couplings when they are not in

use. They protect the couplings from damage and prevent the entry of

Figure 7 Connect Gas Line to Compressor or Cold Head

5. Using two wrenches, connect the RETURN gas line to the RETURN coupling on the cold

head. Tighten the coupling to 47 ± 7 Nm (35 ± 5 ft. lbs.).

Loading...

Loading...