Installation, Operation, and Maintenance Manual

SUMMIT PUMP MODEL SP 20

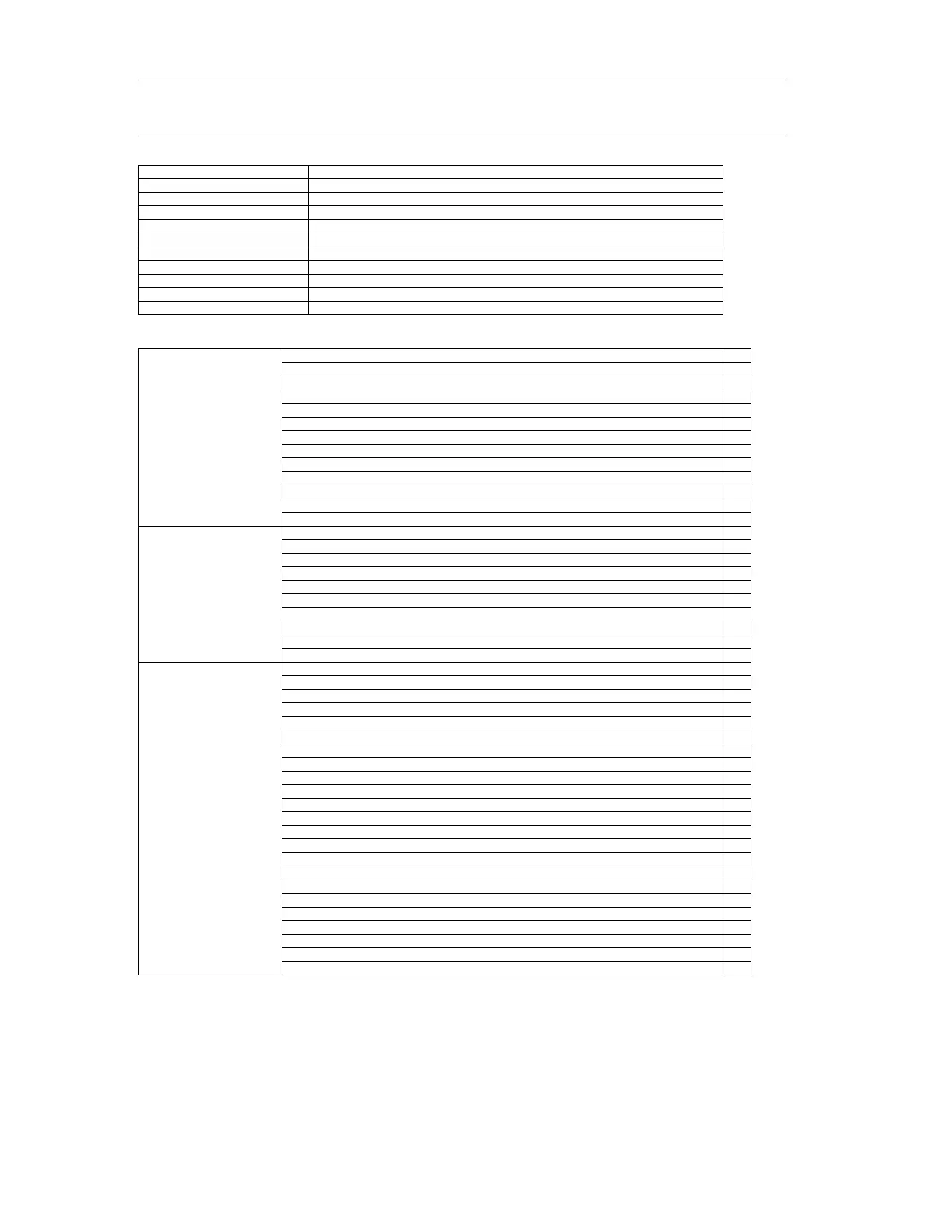

APPENDIX E – TROUBLESHOOTING

1,2,3,4,6,11,12,13,14,16,17,22,23,29,30,37

Reduced discharge delivery

2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,22,23,29,30,37

5,14,15,16,17,20,22,23,29,30,37

2,3,5,6,7,8,11,12,13,22,23,37

Excessive horsepower required

15,16,17,18,19,20,24,26,27,32,33,36

Leakage from stuffing box

24,26,31,32,33,34,35,38,45,46

24,26,28,31,32,34,35,36,38,45,46

Vibration and noise from pump

2,3,4,9,10,11,21,23,24,25,26,27,28,29,34,35,37,39,40,41,42,43,44

24,26,27,28,34,35,40,41,42,43,44

Overheating or seizure of pump

1,4,21,24,27,28,34,35,39,40,41,42

1,5,11,12,13,14,16,17,19,22,23,30,37

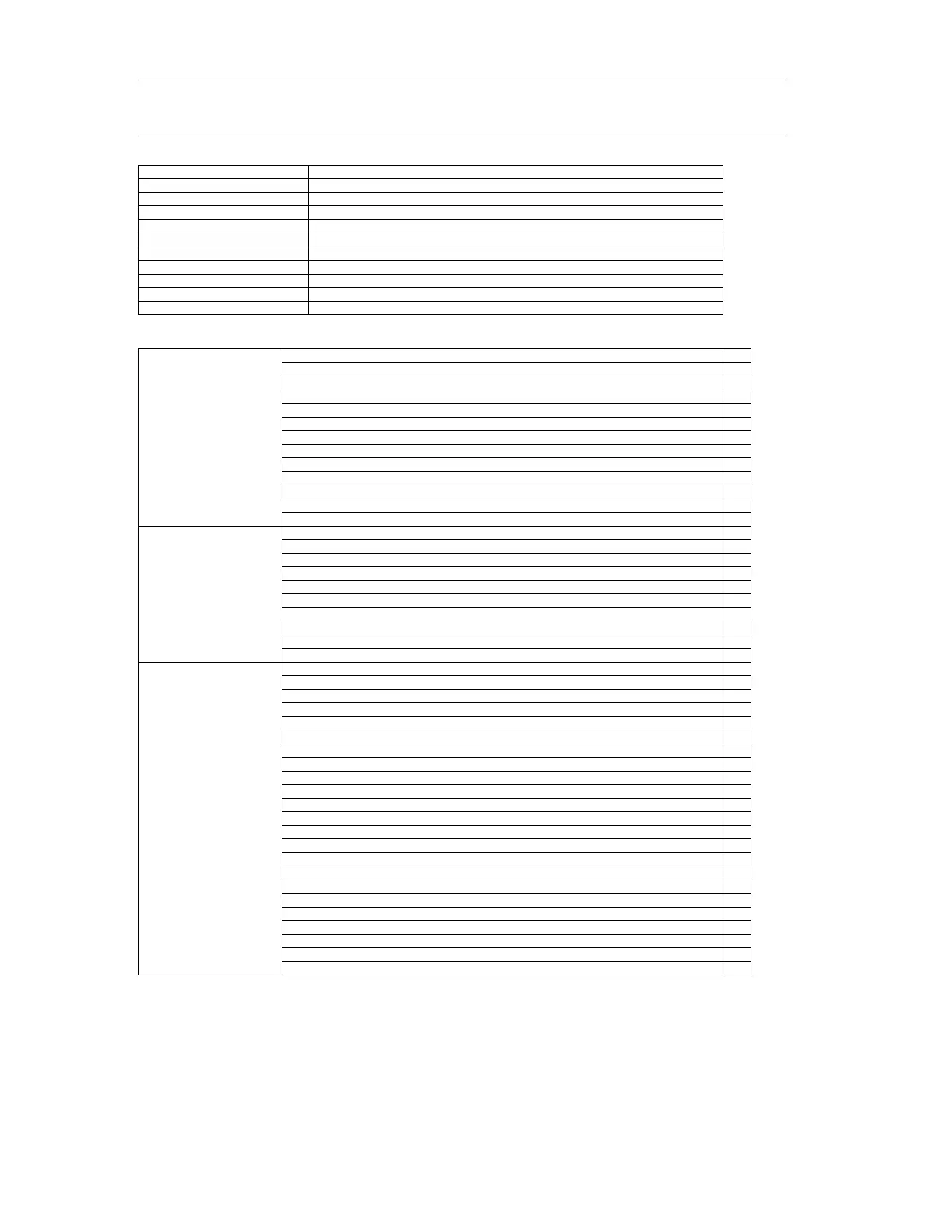

PROBABLE CAUSE AND REMEDY.

INTAKE

The pump or intake is not completely filled with liquid.

The suction lift is too high.

There is insufficient margin between the intake pressure and vapor pressure.

There is an excessive amount of air or gas in the liquid.

There are air pockets in the line.

Air is leaking into the intake line.

There is air leaking into the pump through the stuffing box.

The foot valve is too small.

The foot valve is partially clogged.

The intake pipe is insufficiently submerged.

The intake diameter is too small or the length of the intake pipe is too long.

SYSTEM

FAULTS

The pump is rotating in the wrong direction.

The total head of the system is higher than designed head.

The total head of the system is lower than designed head.

The specific gravity of the liquid is different than the design.

The liquid viscosity differs from design of the pump.

Operating at low capacity.

Entrained air in the pump. The pump hopper requires baffles.

Incorrectly installed pipe line or gaskets partly blocking pipe.

MECHANICAL

FAULT

The foundation is not rigid.

The rotating parts rubbing together.

The impeller is damaged or worn.

The casing gasket is leaking permitting internal leaking.

The shaft sleeve is worn or scored at the packing.

The packing is improperly installed.

The packing is incorrect for the operating conditions.

The shaft is running off center due to bearing ware or misalignment.

The impeller is out of balance resulting in vibrations.

The gland is too tight resulting in no flow of liquid to lubricate the packing.

There is foreign matter in the impeller.

There is dirt or grit in the sealing liquid leading to scoring of the shaft sleeve.

Excessive thrust caused by mechanical failier inside the pump.

There is an excessive amount of lubrication in the bearing housing causing high temperature.

There is a lack of lubrication.

The bearings are installed improperly.

There is dirt getting into the bearings.

There is water in the bearing housing rusting the bearings.

The expeller is worn or blocked.

There is excessive clearance at the bottom of the stuffing box, forcing the packing into the pump.

Loading...

Loading...