Installation, Operation, and Maintenance Manual

SUMMIT PUMP MODEL SP 4

3. INSTALLATION

LOCATION

The pump should be located as close as practical to the supply of liquid. Other location

considerations are easy access for inspection and maintenance and ample overhead space

for lifting with crane or hoist.

The final location consideration is to assure that maximum NPSHa is available at the

suction flange. NPSHa must always be greater than NPSHr.

FOUNDATION

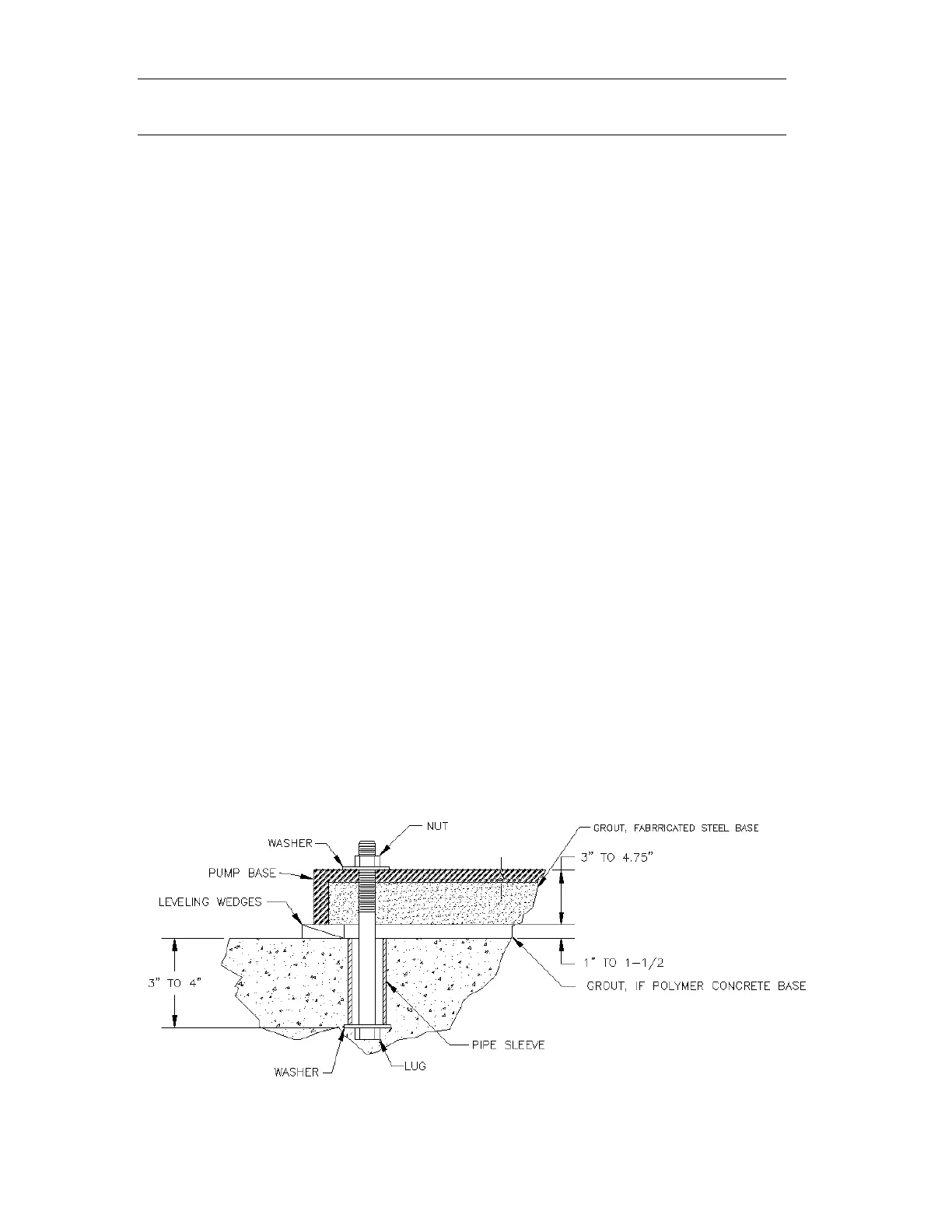

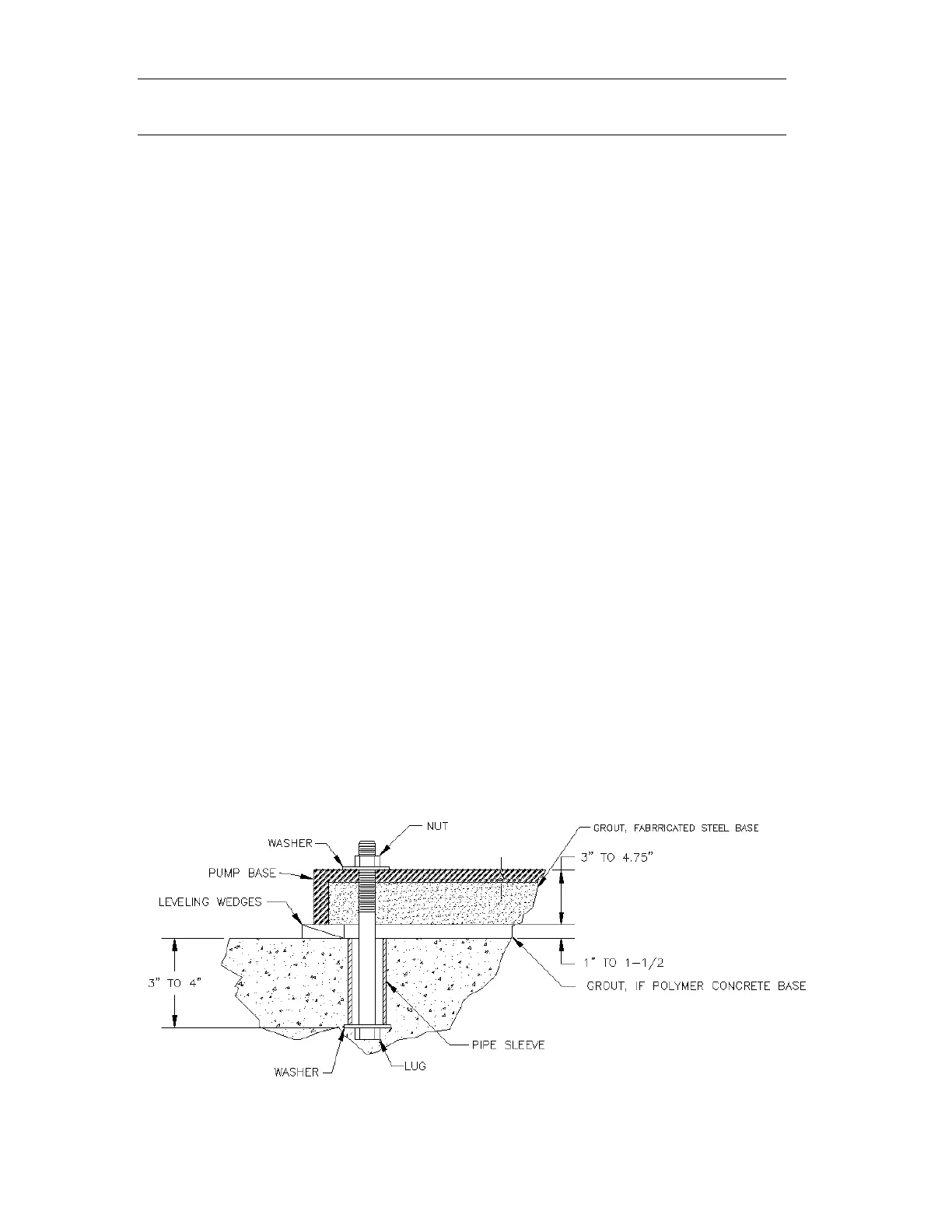

CONCRETE SUB-BASE

The concrete sub foundation performs a number of functions. It must support the weight

of the entire pump assembly, maintain the alignment of all system components, and

absorb the loads, forces and vibrations that are developed under normal operating

conditions. The concrete material used must be top quality and conform to local building

codes as well as the contractor’s strength requirements. Reinforcing bars and mesh

should be used as required. The mounting surface of the concrete foundation must be flat

and level beneath the footprint of the sub-base, or the pump could be installed out of

square. This could create problems aligning the piping, place extra loads on the

couplings and bearings, and alter the operating levels of lubricants or hydraulic fluids in

the system. It is recommended that the top surface of the slab be held flat and level to

Ff50/F150 according to American Concrete Institute (#117) and the Canadian Standards

Association (#A23.1) which is approximately 1/8” per 10 foot.

The mass weight of the sub foundation should be 3-5 times the mass weight of pump,

motor and baseplate. Dimensionally, it should be 3” to 6” longer and wider than the

polymer concrete or fabricated steel baseplate. Anchor bolts are installed in pipe sleeves.

The pipe diameter is 2.5 times larger than the anchor bolt diameter. This sleeve/bolt

assembly is embedded in the base when poured.

Anchor bolt sizes: 1”-8UNC. Length is 7.5 to 10” depending on base thickness and

overall size.

Loading...

Loading...