2-2

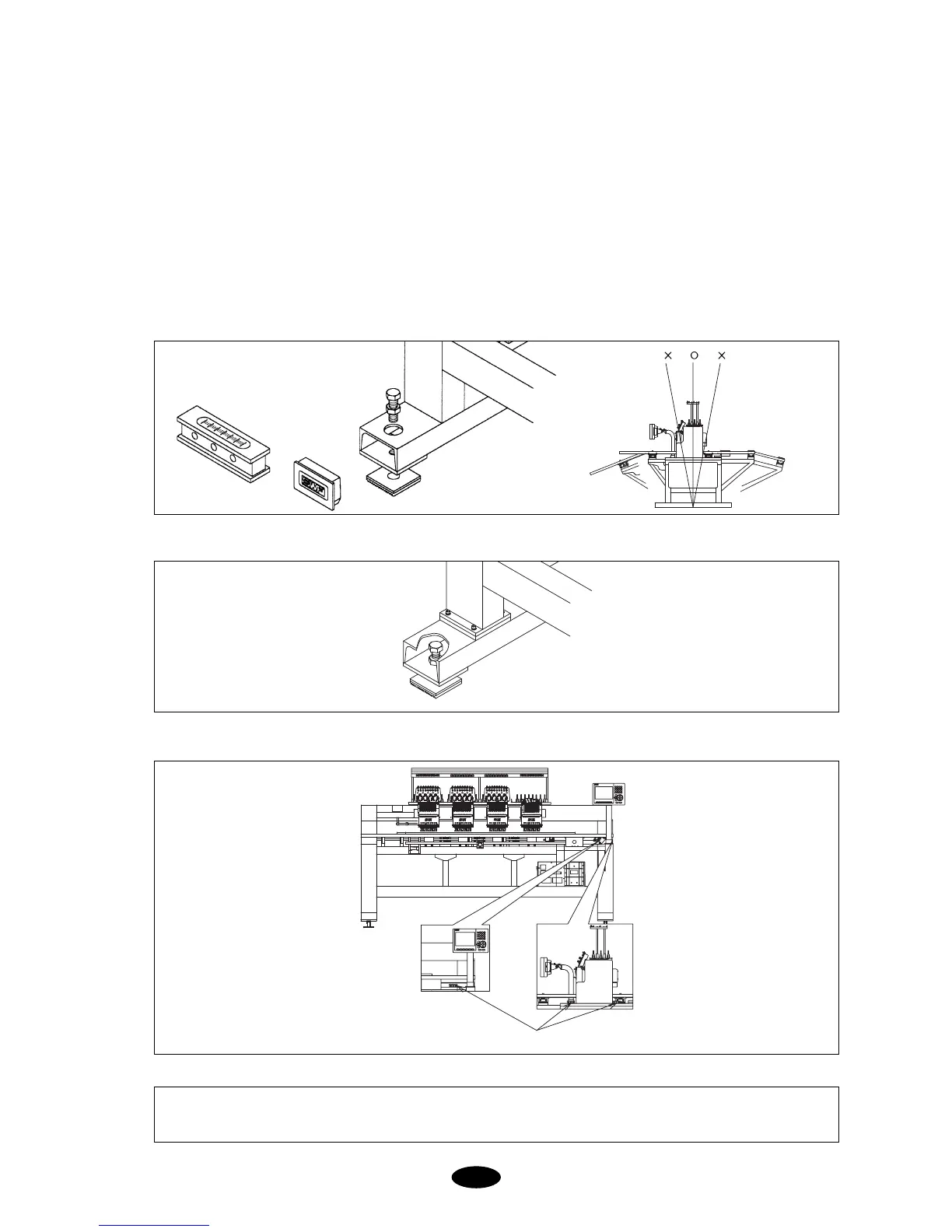

2-3) LEVELING THE MACHINE

The machine must be accurately leveled (especially front and back) to prevent the needle from moving out of

position.

1) Use the adjusting bolts installed at the four stands to level the machine (front, rear, left, and right). Use a level

gauge.

① Check the voltage supply where the machine will be installed.

② Install the cable away from the operator’s work space to prevent accident or injury.

③ If the difference in heights of the four bolts is over 10mm, place spacers beneath the lower adjusting bolts to

make the heights even.

2) Use a nut to fasten the bolts when the machine is horizontally leveled.

[CAUTION]

The level gauge does not measure accurately on a square pipe or a table.

[Fig.2-2]

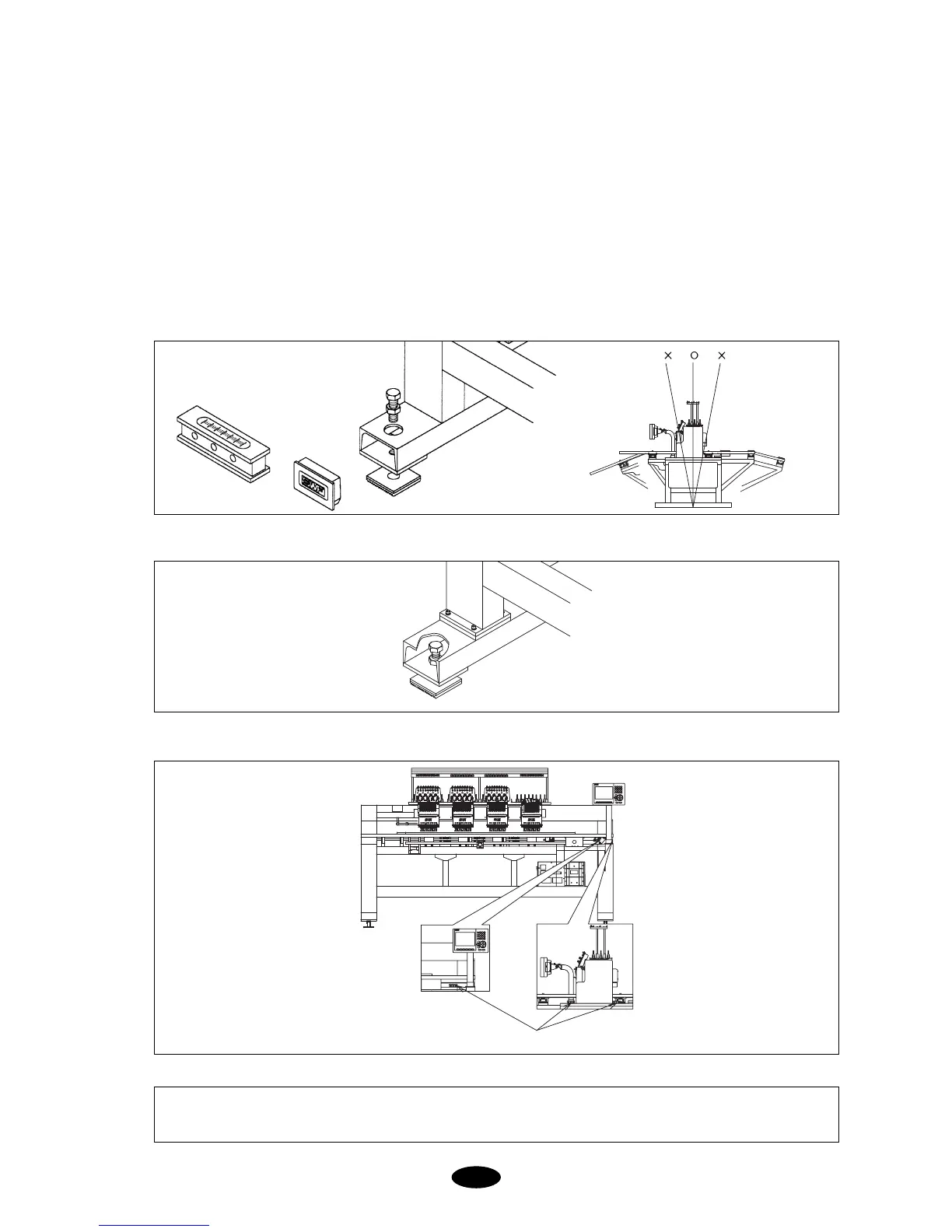

3) Using the level gauge

[Fig.2-3]

[Fig.2-1]

Level gauge

Level gauge

Adjusting bolts

Level base

Loading...

Loading...