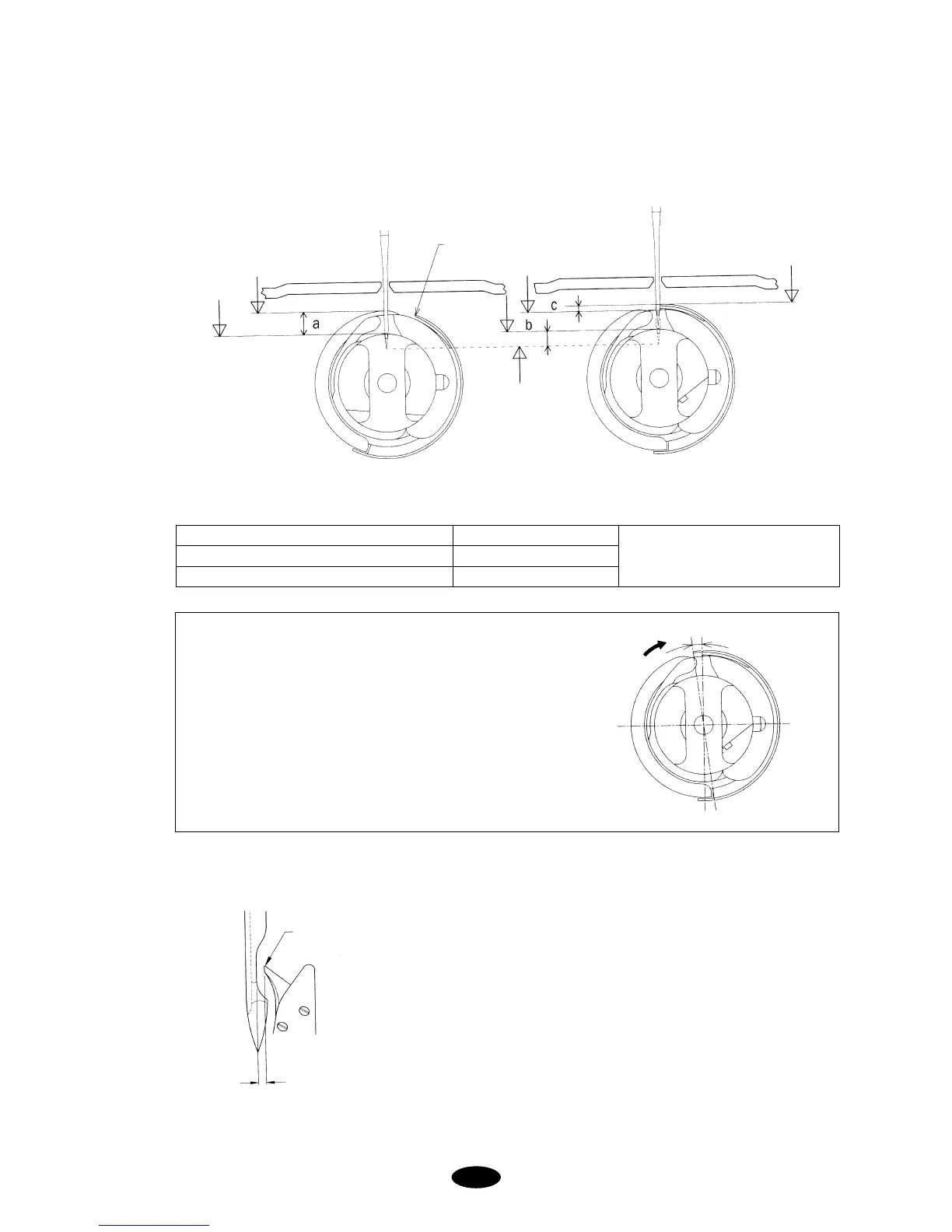

4) Relationship between Needle and Hook

① Adjusting Timing between Needle and Hook

Default timing of the needle and the hook is set by the main shaft angle of 201°and varies as below.

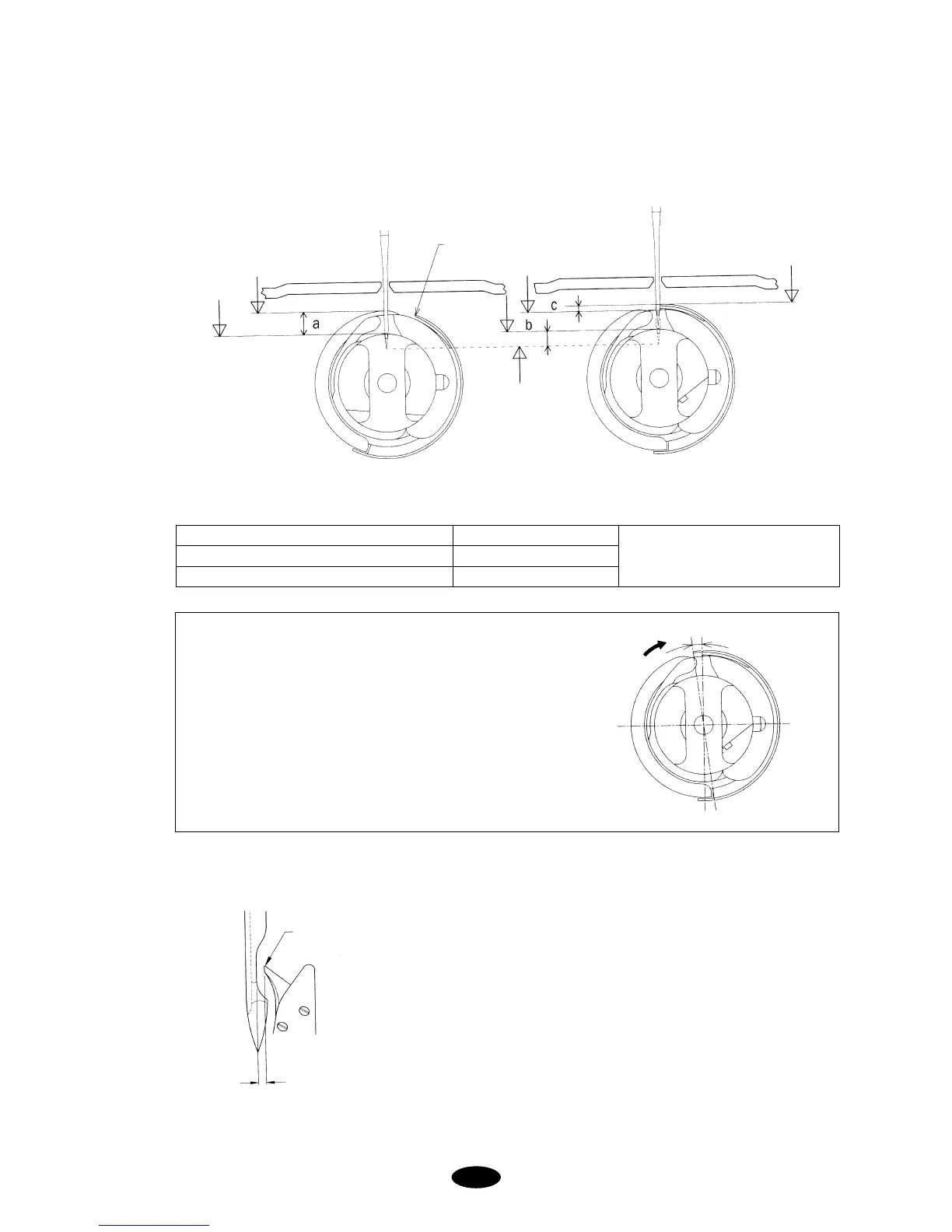

② Adjusting Gap between Needle and Hook Point

5-16

• Gap between the hook point and the scarf of the needle

should be 0.1-0.3 mm minimum.

• Thread skip occurs due to thread looping or inadequate

balance/gap between the needle and the hook. The closer the

hook point is to the needle, the hook point will be inside the

loop and threading will be more stable.

[Fig.5-23]

[Fig.5-25]

Hook point

0.1~0.3mm

[Fig.5-24]

Top edge of

needle eye

Top point of hook

circumference

Needle tip

Top edge of the

needle eye

Hook allowance

(gap)

Hook

point

Lower dead stop

of the needle

Hook point

a. At lower dead stop of the needle bar

2.3~3.7 mm

1.8~2.2 mm

0.5~1.5 mm

The figures may change according

to needle specification/number.

b. At needle-hook timing

c. At needle-hook timing

[CAUTION]

The hook can move right and left if there is an allowance

in the lower shaft gear. Eliminate the allowance (gap) by

turning the hook clockwise. Then adjust the timing.

Loading...

Loading...