13

POWER AND ELECTRICAL SAFETY

The SuperMax Tools 16-32 drum sander requires 110 V, single-phase 20 amp service. After the dust collection sys-

tem is in place and the drum alignment is checked your machine should be ready to be powered up and operated.

ABRASIVE SELECTION GUIDE

To attach a strip to the drum, follow the procedure below.

GRIT COMMON APPLICATION

36 GRIT Abrasive planing, surfacing rough-sawn boards, maximum stock or glue removal

60 GRIT Surfacing and dimensioning boards, trueing warped boards

80 GRIT Light dimensioning, removal of planer ripples

100 GRIT Light surfacing, removal of planer ripples

120 GRIT Light surfacing, minimal stock removal

150 GRIT Finish sanding, minimal stock removal

180 GRIT Finish sanding only, not for stock removal

220 GRIT Finish sanding only, not for stock removal

Note: See page #20 for complete list of pre-cut abrasives offered by SuperMax Tools for this specic unit.

CONNECTING DUST COLLECTORS

Dust collection is necessary for the SuperMax Tools 16-32 drum sander. The sander comes equipped with a 4”

diameter dust exhaust port at the top of the cover. Check to make sure that the minimum dust requirements are

dust collector capacities is 600 cfm. For best results, follow the recommendations of the manufacturer of your

dust collection equipment. When connecting dust collectors straight pipe is preferred because it is the least

Note: Some applications will require more dust collection than the recommended minimum.

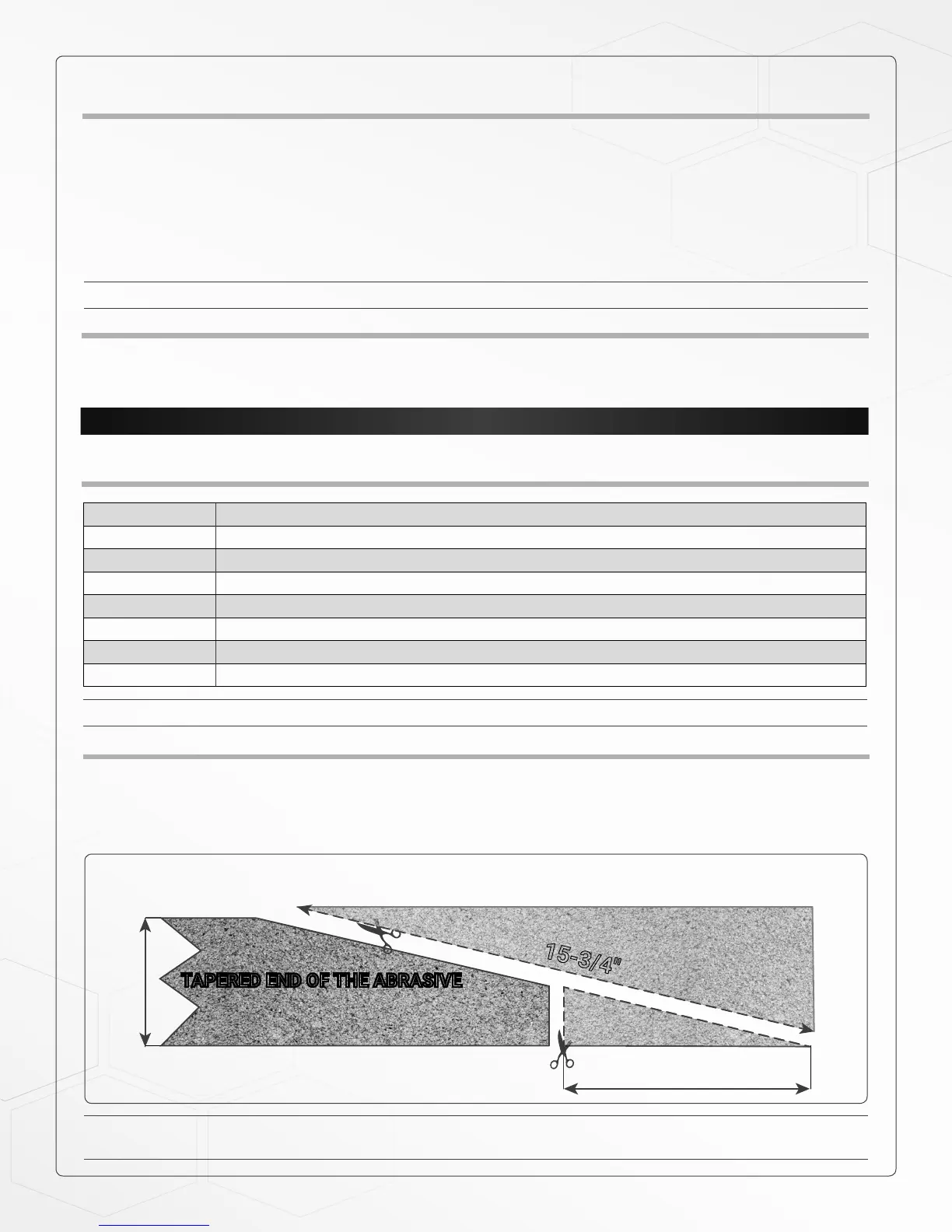

INSTALLING AND WRAPPING ABRASIVES

Accurate attachment of the abrasive strip to the drum is critical to achieving the top performance from your

tapered and attached to the outboard (left) side of the drum. Then the strip is wrapped around the drum, and the

second taper is made for attachment to the inboard (right) side of the drum.

Note: Pre-cut wraps have been factory tapered to the specic width of your drum. If you are cutting your own

abrasive, use the wrap that came on the drum as a template (abrasive side up).

Approx. 3’’

Bande abrasive (côté abrasif vers le haut)

3’’

15-3/4

"

TAPERED END OF THE ABRASIVE

Drum width: 16"

Tip-to-tip: 97"

Wrap ready to install: 91"

Loading...

Loading...