OPERATING YOUR SUPERMAX

15

Begin experimenting with the feed rate set at

about 40% to 50% of maximum. The best feed rate

will depend on a number of factors, including type

of stock, grit and depth of cut used, and whether

the stock is feed directly in line with the conveyor

bed or at an angle. If you observe a ripple effect on

the stock, slow down the feed rate. If the finish is

smooth and the machine is not overworking, you

can experiment with using a faster feed rate.

Also try a faster feed rate if the stock you are

working begins to show burn marks. With cherry,

hard maple and some other hardwoods, using a

shallower depth of cut and a faster feed rate will

help minimize burn marks. Slightly angling the

stock as it is fed into the machine may also help pre-

vent burning the stock.

Because of the wide range of variables, it is impor-

tant to experiment with your specific conditions

and make adjustments to achieve the optimum feed

rate. If problems occur, first check the depth of cut

and/or adjust the feed rate. Refer to Troubleshoot-

ing Your SUPERMAX in this manual, page 19.

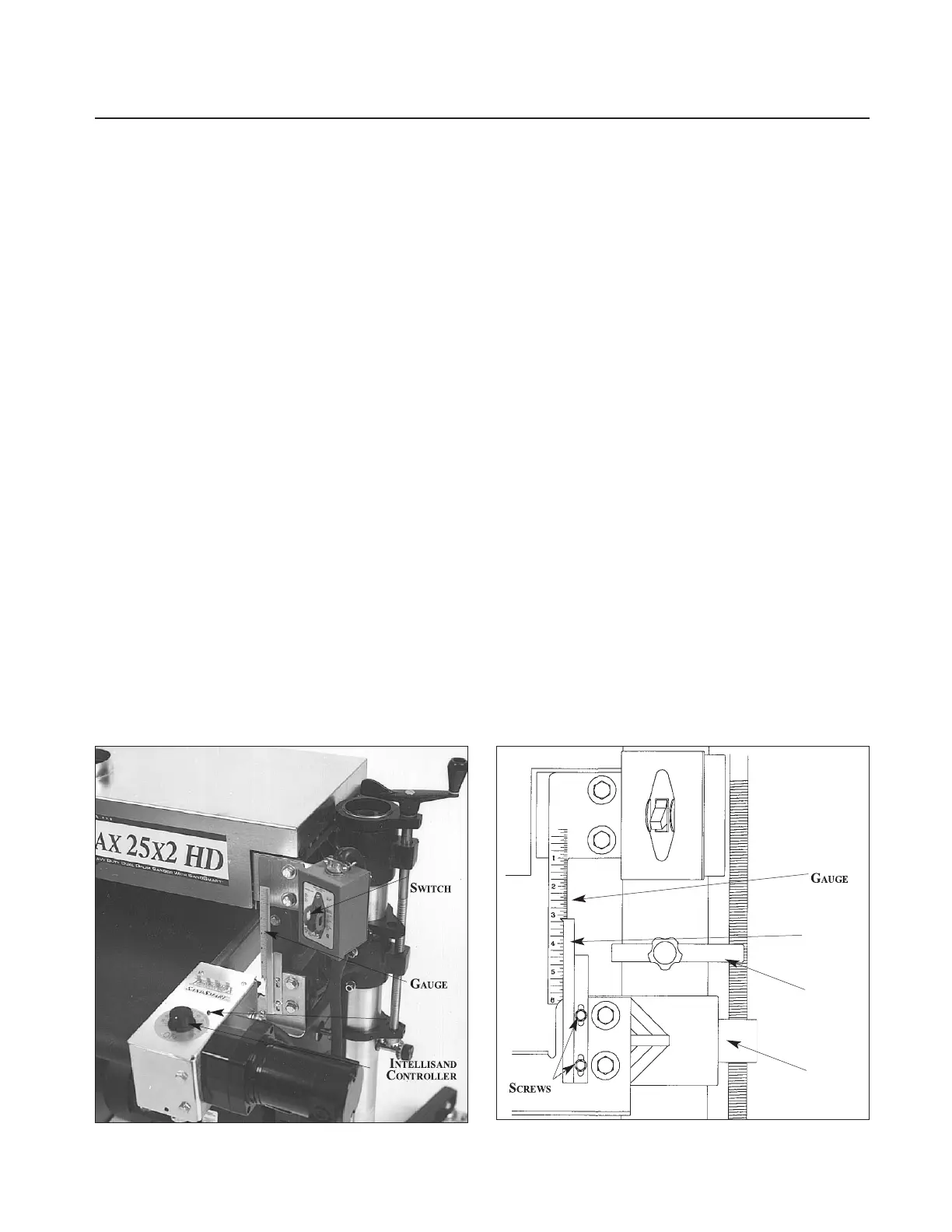

USING THE DEPTH GAUGE

The depth gauge (see Fig. 16) measures the distance

between the conveyor table and the sanding drum

for thickness dimensioning of boards. To calibrate

the depth gauge, raise the conveyor table until the

drum(s), wrapped with abrasive, touches the con-

veyor table. Loosen the two slotted screws holding

the indicator needle to the table mount bracket

(Fig. 16). Raise or lower the indicator needle to read

at zero and tighten the two slotted screws.

USING THE PROSCALE

™

DEPTH GAUGE

The ProScale depth gauge (Page 35, Fig. 45A) has

its own manual. The ProScale can be calibrated by

raising the conveyor until the drum(s) are touching

the conveyor and zero the readout. Another calibra-

tion method is to sand a piece of wood, measuring

the thickness of the wood and change the reading

on the ProScale. See included ProScale manual for

details on calibrating and operation.

USING THE DEPTH STOP

A depth stop (Fig. 16) is located on the column

tube just above the tale support casting on the right

(inboard) side. The depth stop casting has a lock-

ing knob located on one side of the casting. To

operate the depth stop: Determine desired thick-

ness of sanded part by either referencing the depth

gauge or sanding a part and measuring the thickness

of the sanded part. At this sanding thickness, posi-

tion the depth stop along the column tube with the

gauge resting on the table support casting and tight-

en the locking knob on the depth stop. This will

give a desired exiting thickness to the material and

help prevent under dimensioning.

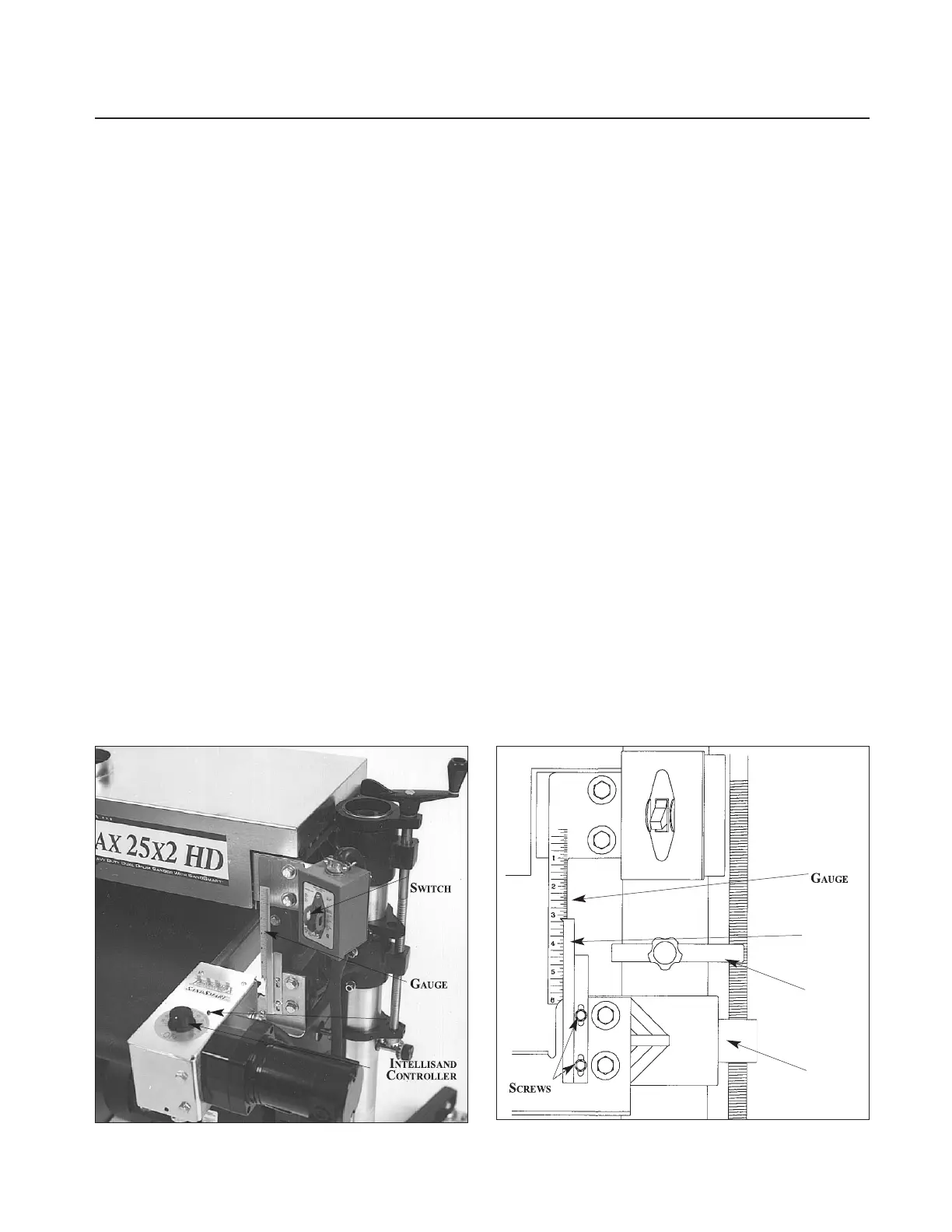

Fig. 15. Intellisand Controller and depth gauge.

Fig. 16. Depth gauge components, on some models.

DRUM

DEPTH

INDICATOR

LIGHT

CALE

EEDLE

EPTH

Loading...

Loading...