24 SUPERMAX OWNER’S MANUAL

SERVICING YOUR SUPERMAX

The basic adjustment procedures for your machine

are covered under Setting Up Your SUPERMAX

Sander, page 6. Review that section first. If follow-

ing the general instructions does not solve a specif-

ic problem or result in smooth operation, also

check Troubleshooting Your SUPERMAX, page 19.

Below are suggested procedures to follow when

more thorough readjustment or replacement is

necessary.

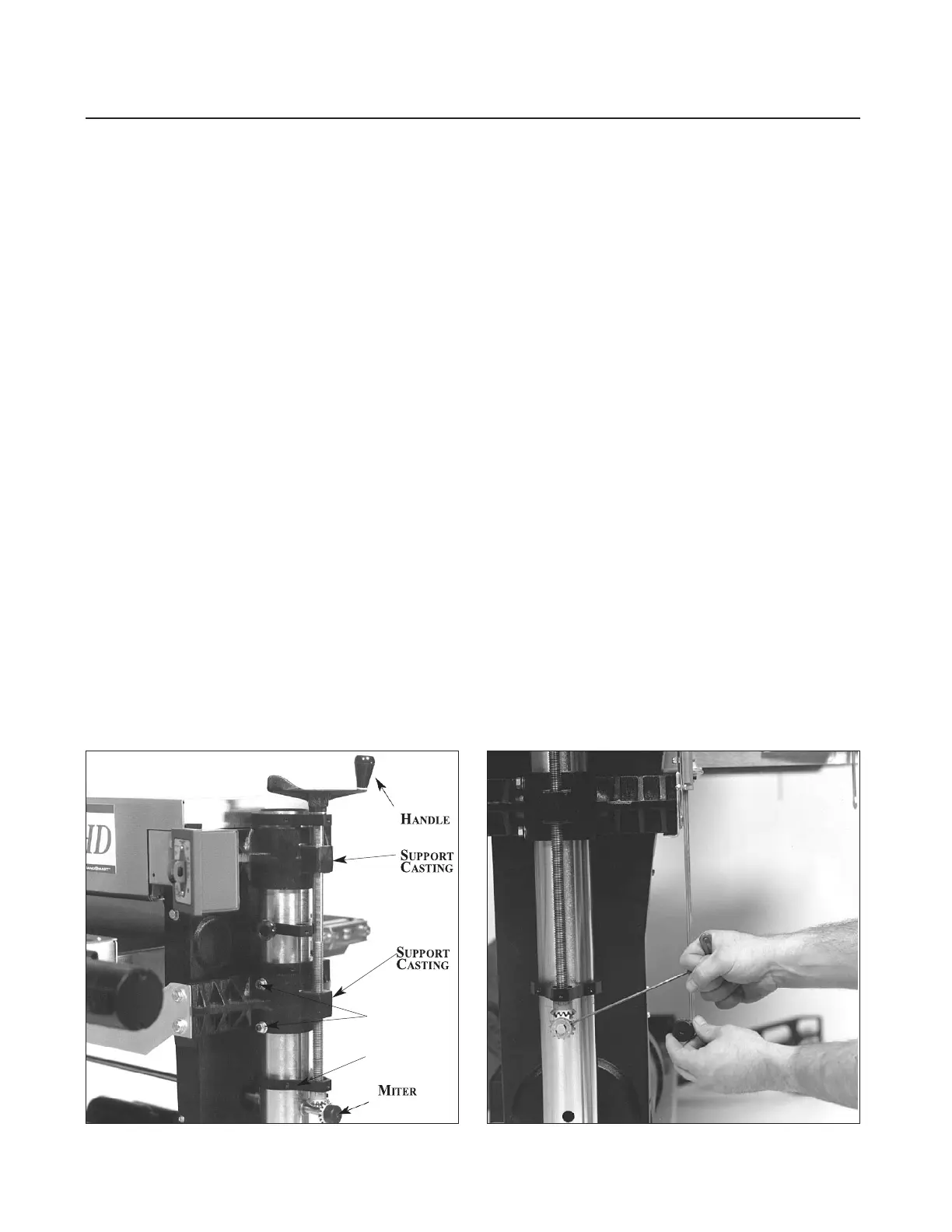

ADJUSTING HEIGHT CONTROLS

Height adjustment problems may be the result of

not loosening the set screws in the table support

castings before attempting operation. (This is cov-

ered on page 5 of this manual, and also on the sep-

arate unpacking sheet which was shipped with

your machine.) If the set screws were not loosened

as instructed, do so now before proceeding further.

Also make sure all moving parts of the height

adjusting mechanism are well lubricated, including

the miter gears, column tubes, and threaded

height adjusting screws.

When troubleshooting the height adjustment

mechanism, first check the conveyor table for level

(see page 7). Then test the height adjustment

mechanism (See Fig. 19). If it does not operate

easily, further adjustments may be necessary, as

outlined below. Following these steps should result

in smooth operation.

Readjustment Procedure

1. Loosen the set screws located at the front of the

table support castings (Fig. 19).

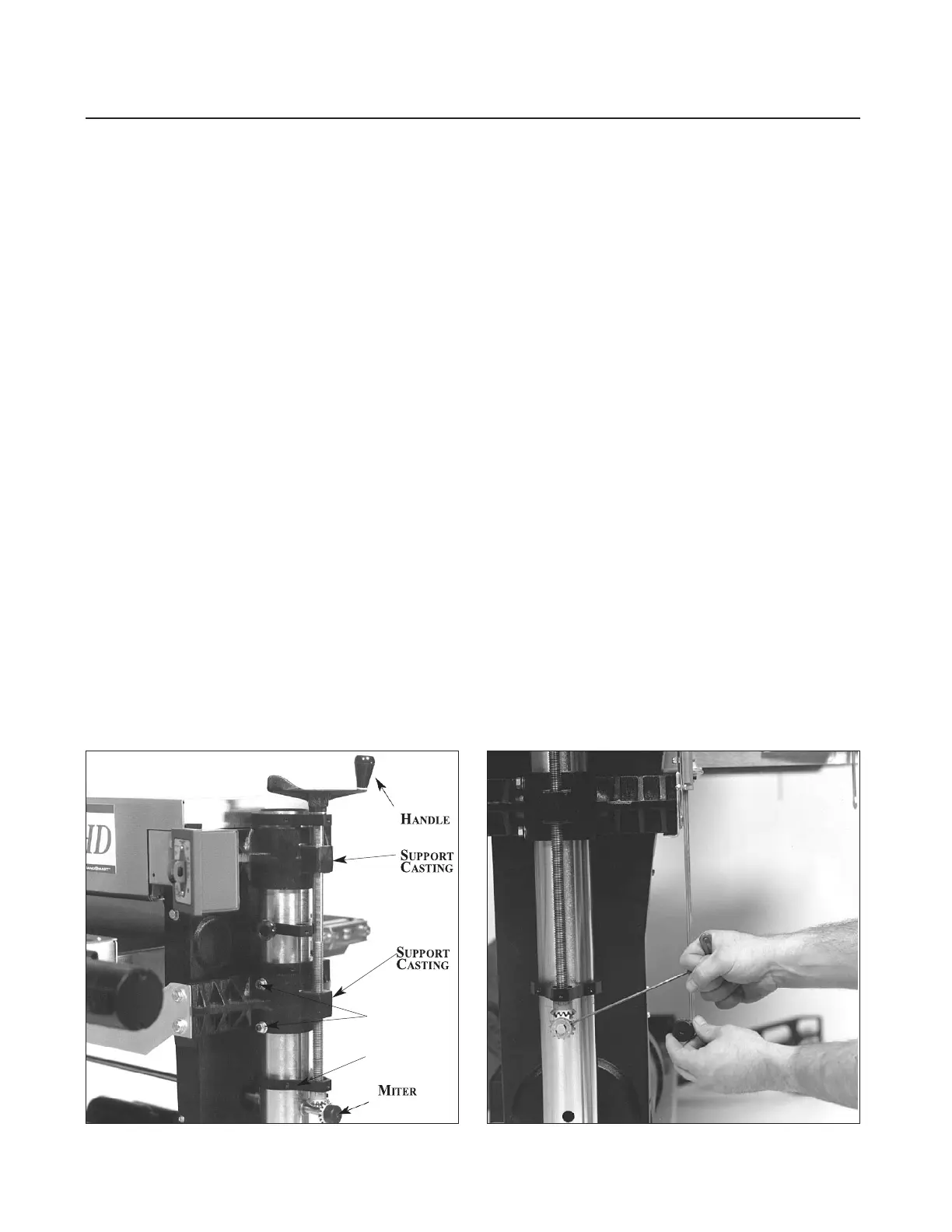

2. Lubricate thoroughly by applying penetrating

lubricant to the table support castings where they

contact the column tubes, and to all contact points

of adjusting screws and cross bar (Fig. 20). Also

apply oil or grease to the miter gears.

3. If the height adjustment feels stiff, check for

misalignment of adjusting screw supports and the

drum support castings which could cause binding

on the adjusting screw rods (Fig. 19). These cast-

ings can be adjusted by loosening the set screws

which secure them to the column tubes. Realign

the adjusting screw supports by loosening the two

set screws that hold them to the column tubes and

rotate to the proper position.

4. The adjusting screw supports located immedi-

ately below the height adjustment handle and the

Fig. 19. Table support casting set screws. Fig. 20. Adjusting miter gears for proper mesh.

H

ADJ.

DRUM

TABLE

HEX NUT

SET SCREW

ADJ. S

SUPPORT

GEAR

Loading...

Loading...