OD

V-BELT

32 SUPERMAX OWNER’S MANUAL

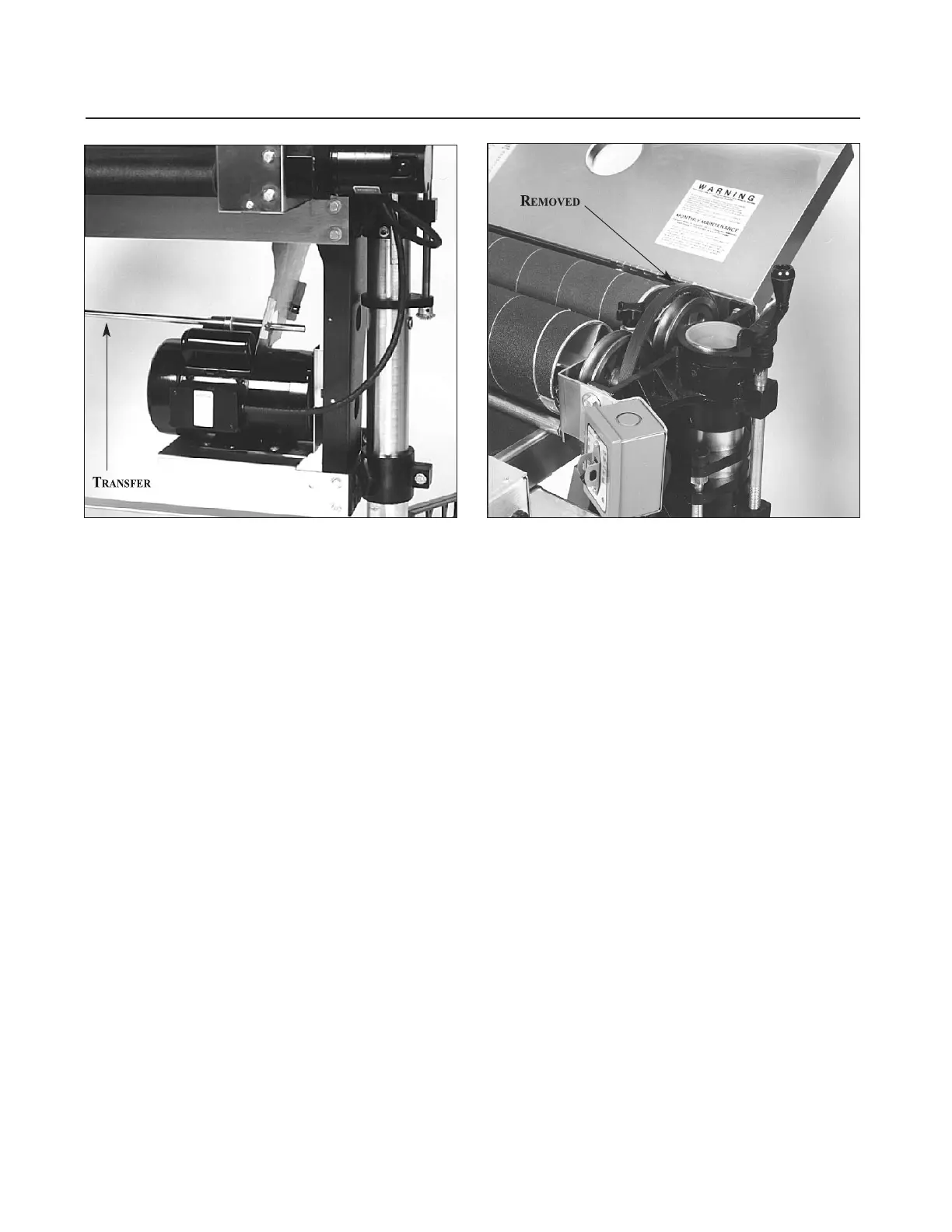

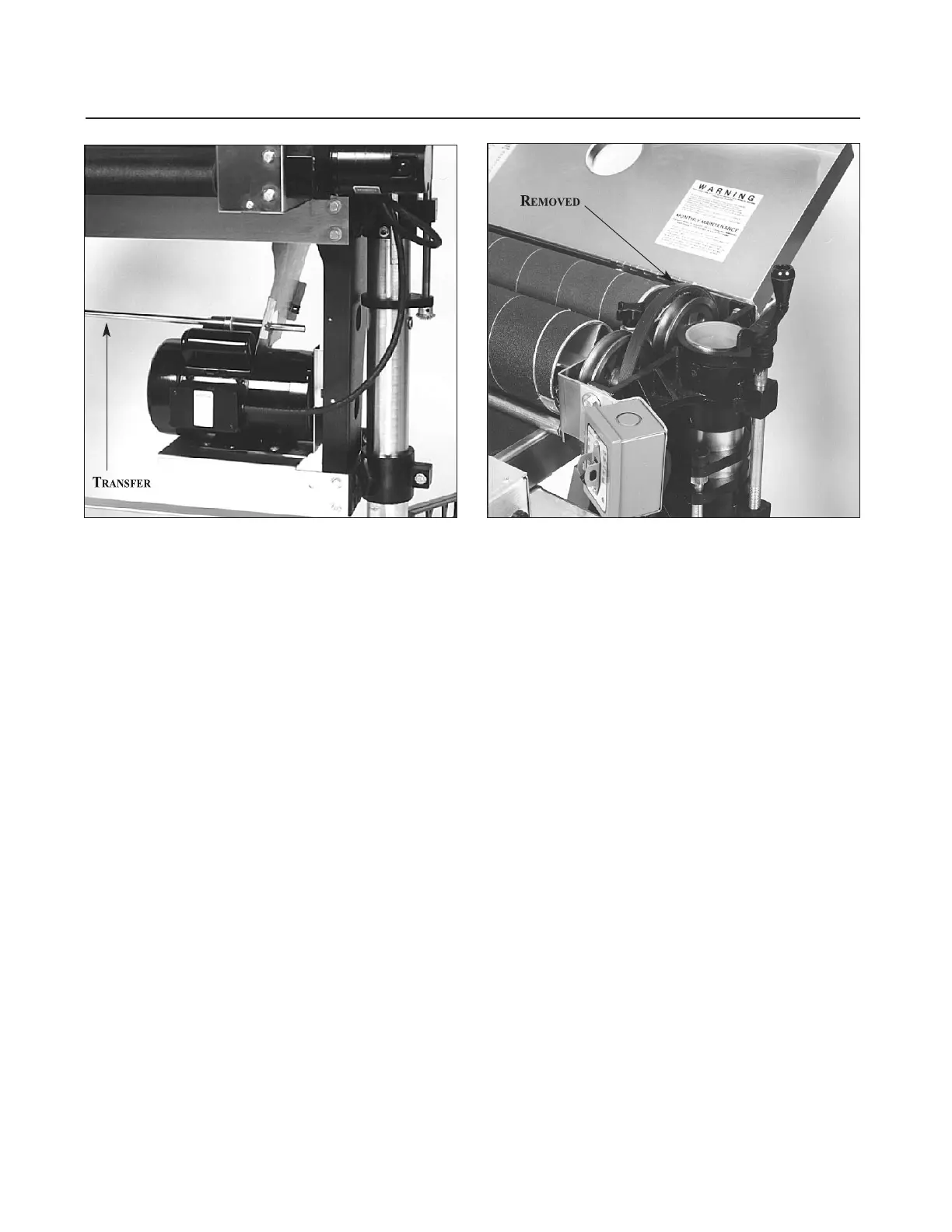

Fig. 37. Removing belt guard and transfer rod. Fig. 38. Removing main motor V-belt drive.

Step 2. Now repeat Step 1 on the right (inboard)

side of the conveyor. Compare the measurements

from side to side. If they are not equal, loosen one

of the brackets that hold the drive or driven roller

in place. Tip this bracket until the distance

between the drive or driven roller and the straight-

edge are equal from side to side, then tighten the

bracket.

REPLACING V-BELT

To change the V-belt on the SUPERMAX, first

unplug machine from the outlet. Remove two

screws in lower section of belt guard and loosen

the pinch bolt of the motor support casting. Raise

the motor and retighten the pinch bolt. The pro-

cedure is the same for single drum sanders except

that there is one driven pulley instead of two.

V-Belt Removal

1. Remove the lower outer belt cover by removing

the four 10-32 screws holding it in place (see Fig.

29 and 37). Remove the two 5/16" x 1/2" hex

head bolts holding it in place; pull the middle

cover to the left. Take the V-belt off the pulley

(Fig. 38).

2. Loosen the pinch bolt of the motor support

casting, raise the motor, and re-tighten pinch bolt.

3. Remove the miter gear from the right (inboard)

side of the transfer rod. Loosen the shaft collar on

the left (outboard) side of the rod, and pull the rod

back enough so the V-belt can be removed. Note

the routing of the old V-belt; now remove the old

V-belt and replace it with the new V-belt.

Machine Reassembly

1. To reassemble the unit after replacing the V-

belt, first place the transfer rod back through the

machine. Tighten the shaft collar. Reinstall the

miter gear on the transfer rod, making sure the set

screw is centered on the flat of the rod.

2. Adjust the tension on the V-belt by sliding the

motor down and then tightening the pinch bolt in

the motor support casting. Adjust so the belt

deflects about 1/2" between the pulleys when

pressed. Excessive tension can increase motor load

and decrease bearing life, while a loose belt can

reduce operating efficiency and shorten belt life.

3. Reinstall the outer and middle belt guard using

the two 5/16" x 1/2" hex head bolts and the four

10-32 screws.

Loading...

Loading...