INBOARD

KNOB

SHAFT

INDICATOR

NEEDLE

SCALE

HEX NUT

8 SUPERMAX OWNER’S MANUAL

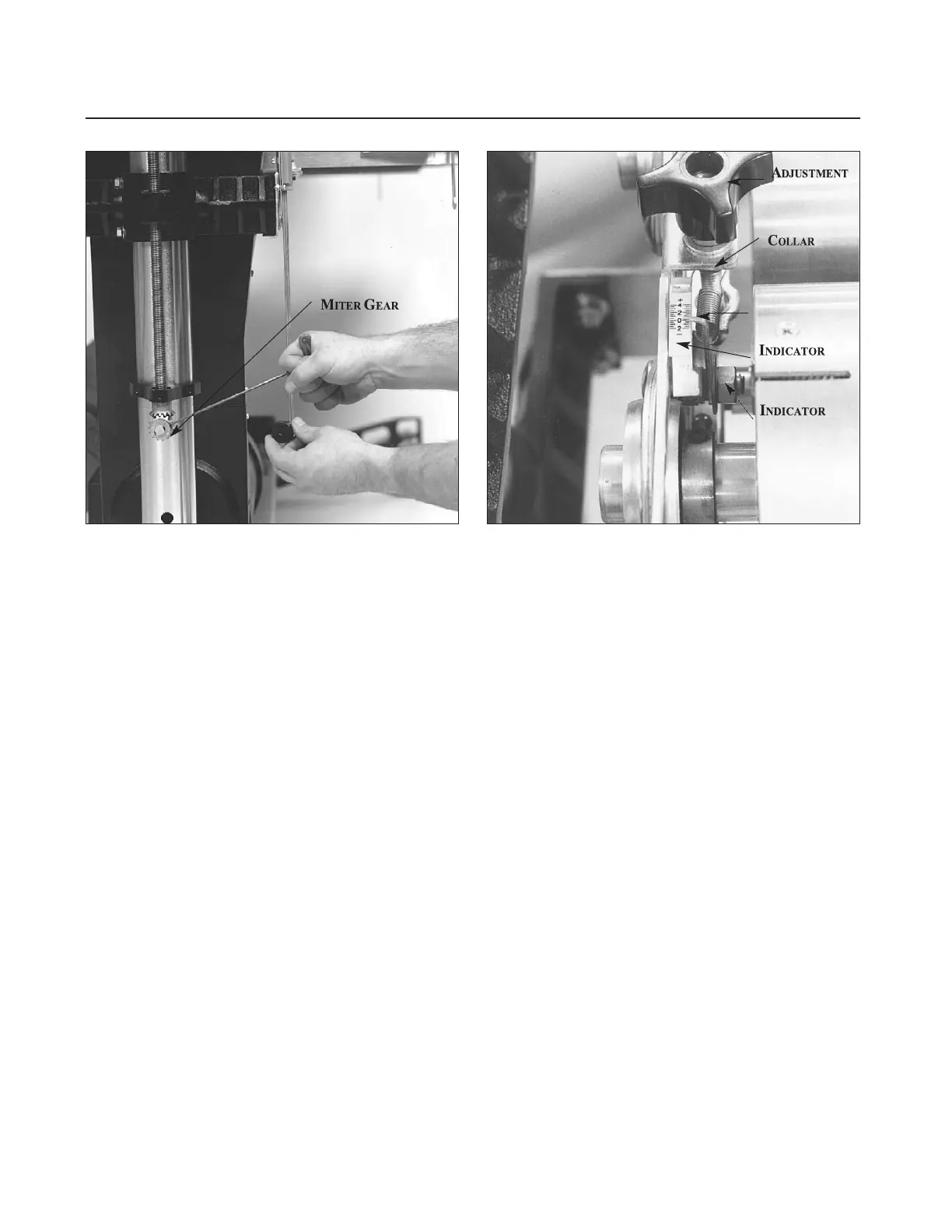

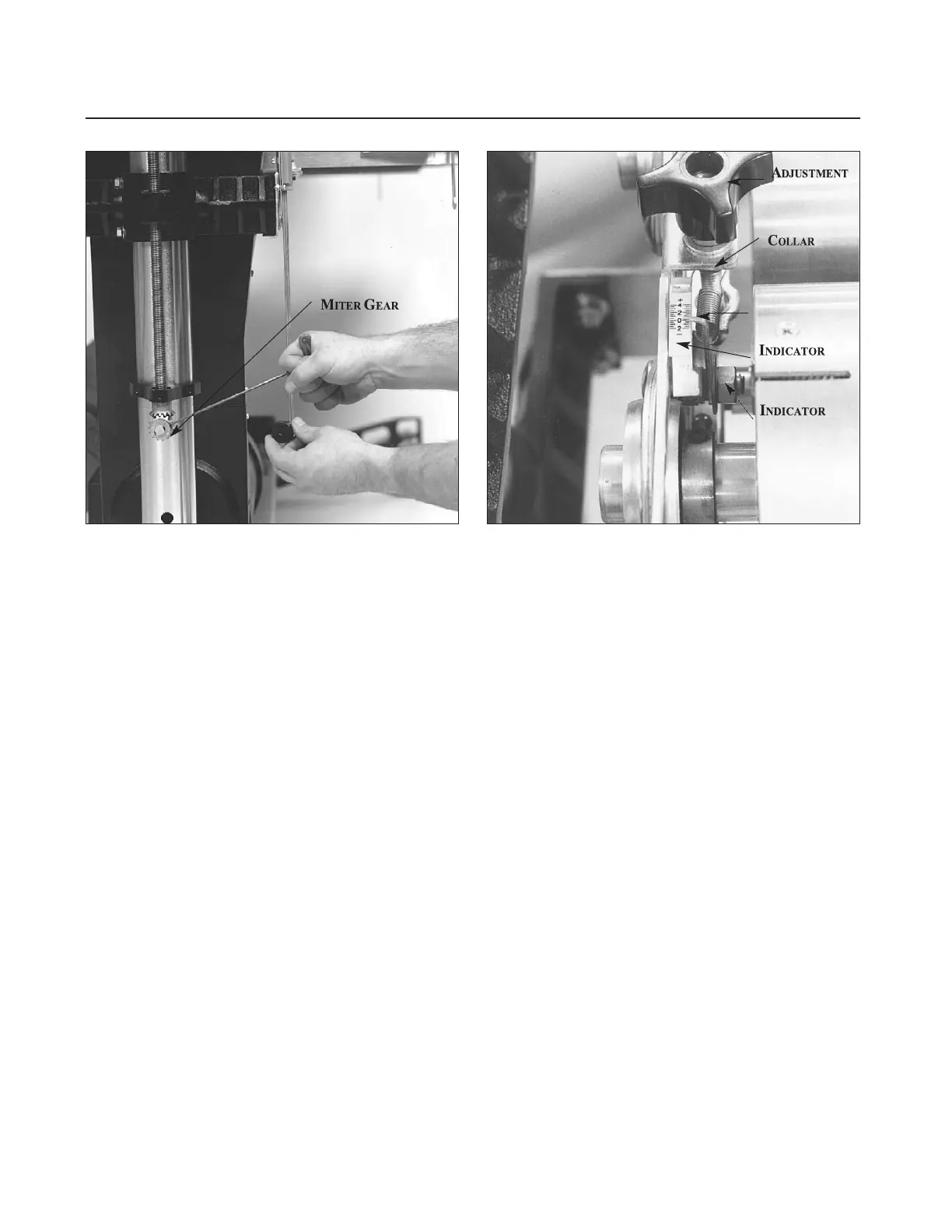

Fig. 8. Adjusting primary drum alignment. Fig. 9. Rear drum adjustment indicator.

the right (inboard) miter gear (see Fig. 8), finely

raise or lower the right (inboard) side of the table

to achieve parallel alignment of the front (primary)

drum. The distance between the conveyor table

and both sides of the front drum should be the

same. Reinstall the miter gear, aligning the set

screw to the flat of the shaft.

Dual Drum Models: Before altering this con-

veyor table position, also check to see that the rear

drum (dual drum models only) is likewise parallel

to the conveyor table, with both sides at the same

height above the table. Using the same thickness

gauge, check both sides of the rear drum from the

rear of the machine while holding up the rear ten-

sion roller. Adjustment of the rear drum is done by

using the right and left drum adjustment knobs

(see Fig. 9).

After the rear drum is adjusted, it is important to

reset the rear drum adjustment indicators to zero

on both sides. Set the secondary drum adjustment

indicators by loosening hex nut, then moving the

indicator scale so that the zero mark is directly

under the needle, and retightening the hex nut

(see Fig. 9). Likewise, zero the indicator for other

side of drum. Take care not to overtighten the hex

nut of the indicator. This can flare the brass bush-

ing and render the indicator inoperable.

Also check that the secondary drum adjustment

knobs turn with a slight resistance to avoid any

movement during operation. To adjust knob resis-

tance, turn the knob clockwise to reveal the set

screw on the shaft collar below the bracket, then

loosen the screw. Making sure the adjustment

knob is tightly seated on top of the bracket, raise

the shaft collar up against the bracket from below

and retighten the set screw.

Note: The nut of the

rear bolt on the rear (secondary) drum bearing

bracket should be backed off a quarter-turn

from being fully tightened. This allows the lock

washer to be depressed slightly but not complete

-

ly. This is the pivot point for the rear drum.

CHECKING THE CONVEYOR BELT

Conveyor belt tension and tracking adjustments

may occasionally be necessary during break-in and

normal operation to compensate for belt stretching.

Install Ceramic Guides at this time. See the

Ceramic Guides instruction sheet inside Ceramic

Guides box, for details. Ceramic Guides are pack-

aged separate on sander.

Belt Tension. To adjust the tension of the convey-

or belt, first adjust the take-up screw nut (see Fig.

10) on both sides of the conveyor to obtain approxi-

mately equal tension on both sides of the belt when

taut. Insufficient belt tension will cause slippage of

conveyor belt on the drive roller during sanding

operation. The conveyor belt is too loose if it can be

stopped by hand pressure applied directly to the top

of the conveyor belt. Excessive belt tension can

Loading...

Loading...