SERVICING YOUR SUPERMAX

33

4. Make sure that the pulleys are in alignment by

holding a straightedge across their flat sides and

adjusting to it. Also check that all bolts are tight

before using the sander.

ROTATING/REPLACING DRUM BEARINGS

Replacing the permanently lubricated drum bear-

ings on the SUPERMAX sander is a relatively

straight-forward procedure. Bearings should be

replaced when they allow excessive play of the

drum, make excessive noise, or otherwise indicate

failure.

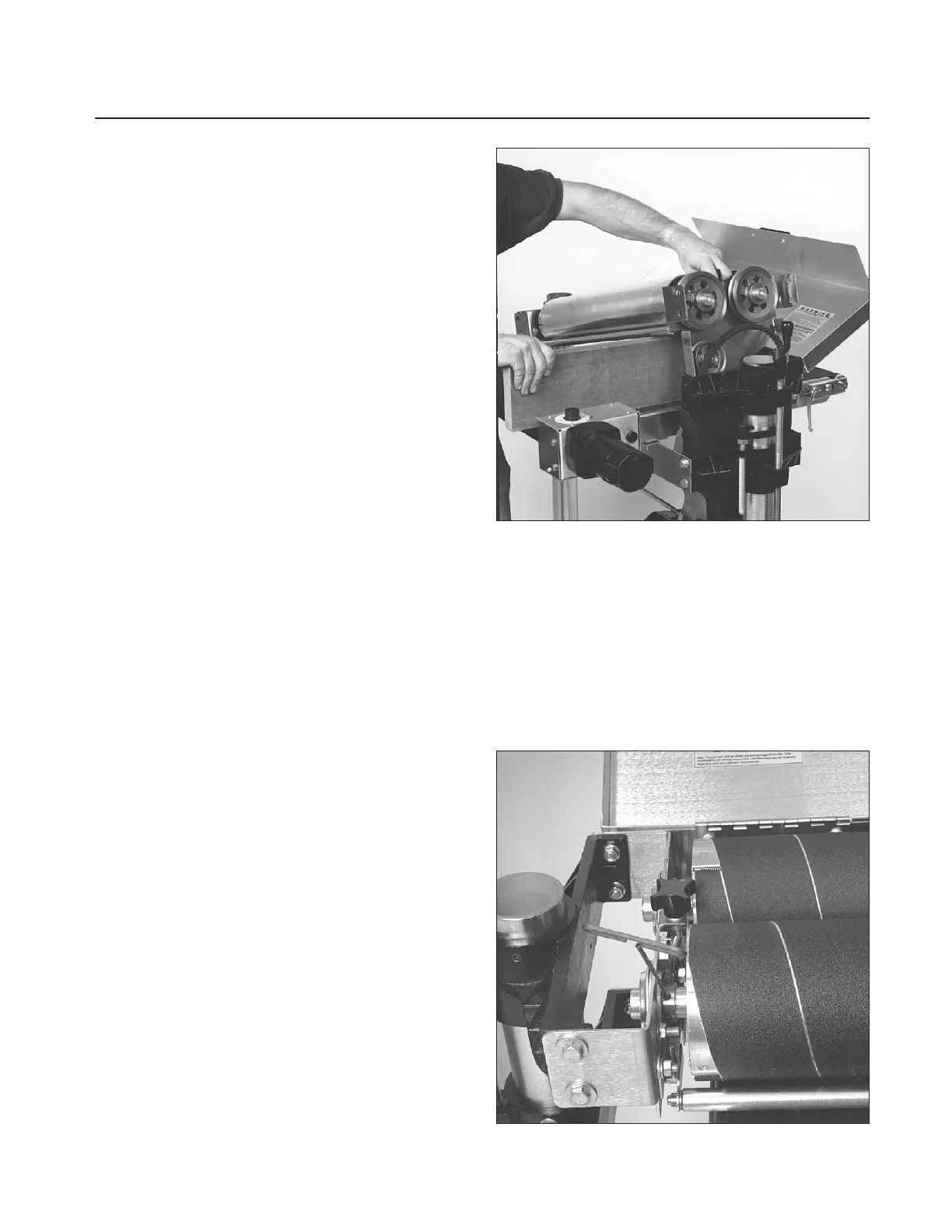

Note that if clicking noises in the bearings are a

problem, rotating may be a solution instead of

replacement, as follows (See Fig. 40):

Rotating Bearings

Step 1. Loosen the set screws in the bearing collar.

Leave the allen wrench in one of the set screws.

Then rotate the drum within the bearing and

tighten the set screws.

Step 2. If the clicking persists, or if the drum shaft

is tight in the bearing and cannot rotate, then

loosen the two bolts holding the bearing and the

flange for the bearing. Now repeat Step 1. After

the drum is rotated within the bearing, tighten the

flanges first and then the set screws. Note: After

tightening the rear bolt in the flange, loosen it

approximately 1/4 turn, which allows the rear

drum to pivot. After the machine has run for a

half hour, stop to check that the set screws and

bearing bolts are tight.

The general procedure outlined below suggests

replacing bearings on the left (outboard) side, one

at a time, starting with the rear drum of dual

drum sanders, then moving to the front drum.

Then, if needed, proceed to the right (inboard)

side, also working on the rear drum of dual drum

sanders first, then the front drum.

Disassembly Procedure

1. To begin the procedure in all cases, disconnect

power to sander.

2. Remove the outer belt guard cover by removing

the two 5/16" x 1/2" hex head bolts holding it in

place, then the four 10-32 screws in the lower half.

Slide the middle section back and the outer guard

to the side.

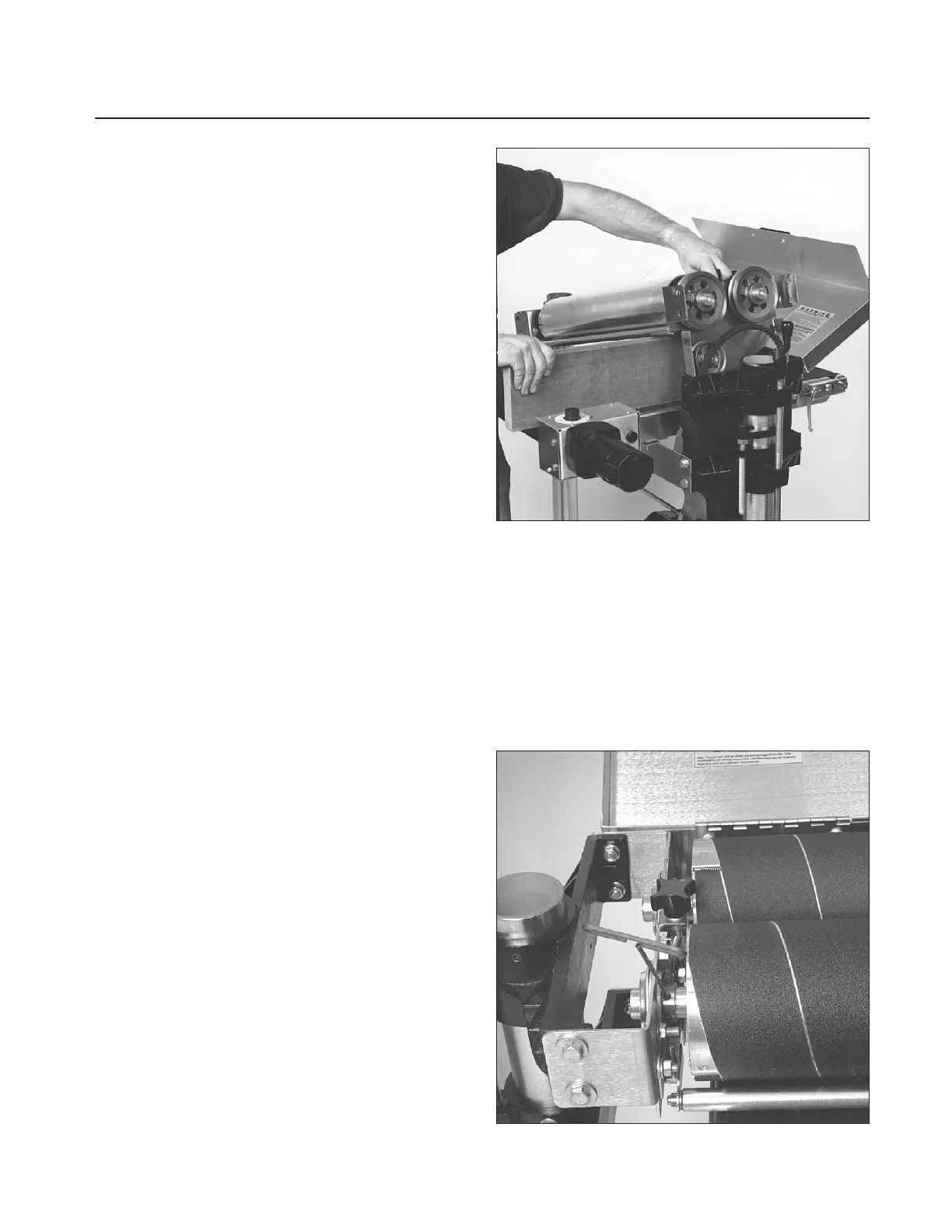

Fig. 39. Supporting drums to remove bearings.

3. Loosen the pinch bolt of the motor support

casting and raise the motor to loosen the V-belt.

4. Next, level the drums to each other (see pages 7

and 8 in this manual). Then raise the conveyor

bed until the drum(s) rest on the conveyor bed.

With this done, follow the steps below:

Fig. 40. Locating bearing set screws.

Loading...

Loading...