18 SUPERMAX OWNER’S MANUAL

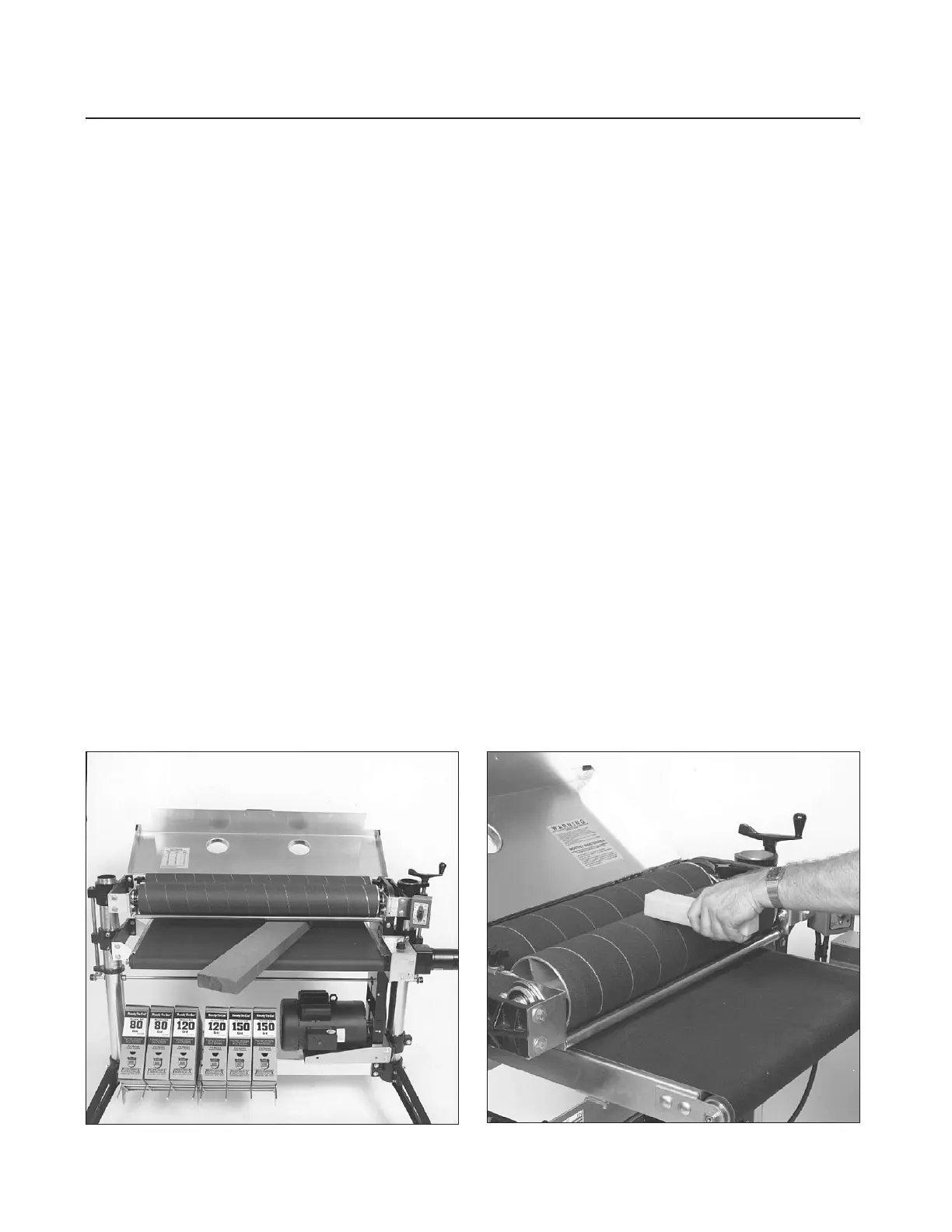

drums). However, even a slight offset angle of the

stock will provide for more effective stock removal.

The optimum feeding angle for stock removal is

about 60° (see Fig. 17). Angling the workpiece for

stock removal provides other advantages, such as

less loading of certain areas of the drums due to

glue lines or mineral streaks in the stock, more

even wear of abrasive strips, potentially faster feed

rates, and lighter loads on the motor.

Note that to get the best final finish, however,

the stock should be fed through the machine so it

will be sanded in line with the grain of the wood

on the final one or two passes.

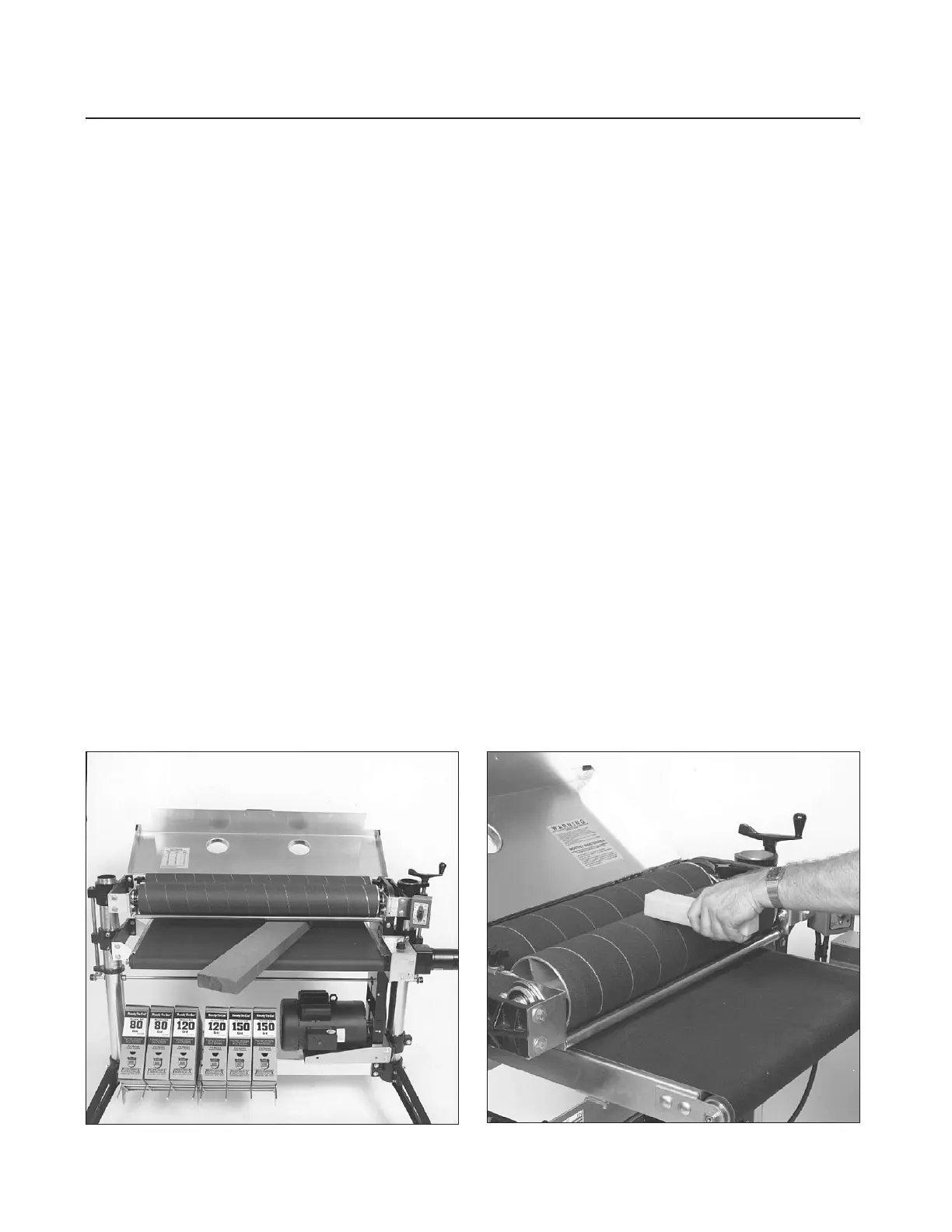

Cleaning Abrasive Strips. Regularly clean the

abrasive strips on the drums with commercially

available cleaning sticks, following the manufac-

turer’s directions. (See Fig. 18.) Cleaning sticks are

available from your dealer or from SuperMax

Tools. When cleaning, also brush the stick crumbs

from the drum while it is still rotating. Important:

Wear eye protection, tight-fitting clothes and keep

alert during this operation to avoid injury. Cloth-

backed abrasives can be cleaned by soaking in

paint thinner or mineral spirits for 20 minutes to

1 hour, then using a brush to remove any build-up

or burns. Dry the abrasive strips completely before

reuse. In some cases build-ups resulting from

burns can be removed with Plexiglas held on edge

over a rotating drum. Have dust collection turned

on when cleaning.

Stretching Abrasive Life. When sanding metal or

solid surface, MDF, or particle board, ceramic abra-

sive (Regalite™) will last longer than aluminum

oxide and also allow a more uniform finish.

Abrasive life can also be increased on SUPERMAX

machines by removing the abrasive strip from the

drum and reversing it. To do this, remove the strip

and use what was the trailing end as the starting

end on the left (outboard) side of the drum.

Reversing the strip will provide a fresh set of cut-

ting edges on the drum.

Keeping The Machine Clean. For best results,

make cleaning the machine a regular shop proce-

dure. Allowing excess build-up of dust and debris

can adversely affect performance through the load-

ing of the abrasives, slippage on the conveyor

table, and/or the accumulation of material inside

the drums which can throw off the center of bal-

ance. Leave the dust collector on when cleaning

dust from the drums. Also brush the conveyor belt

after cleaning operations. If not cleaned, the con-

veyor belt could allow stock to slip during sanding

operations.

Fig. 17. Offset stock feeding angle. Fig. 18. Cleaning abrasive strips.

Loading...

Loading...