TROUBLESHOOTING YOUR SUPERMAX

21

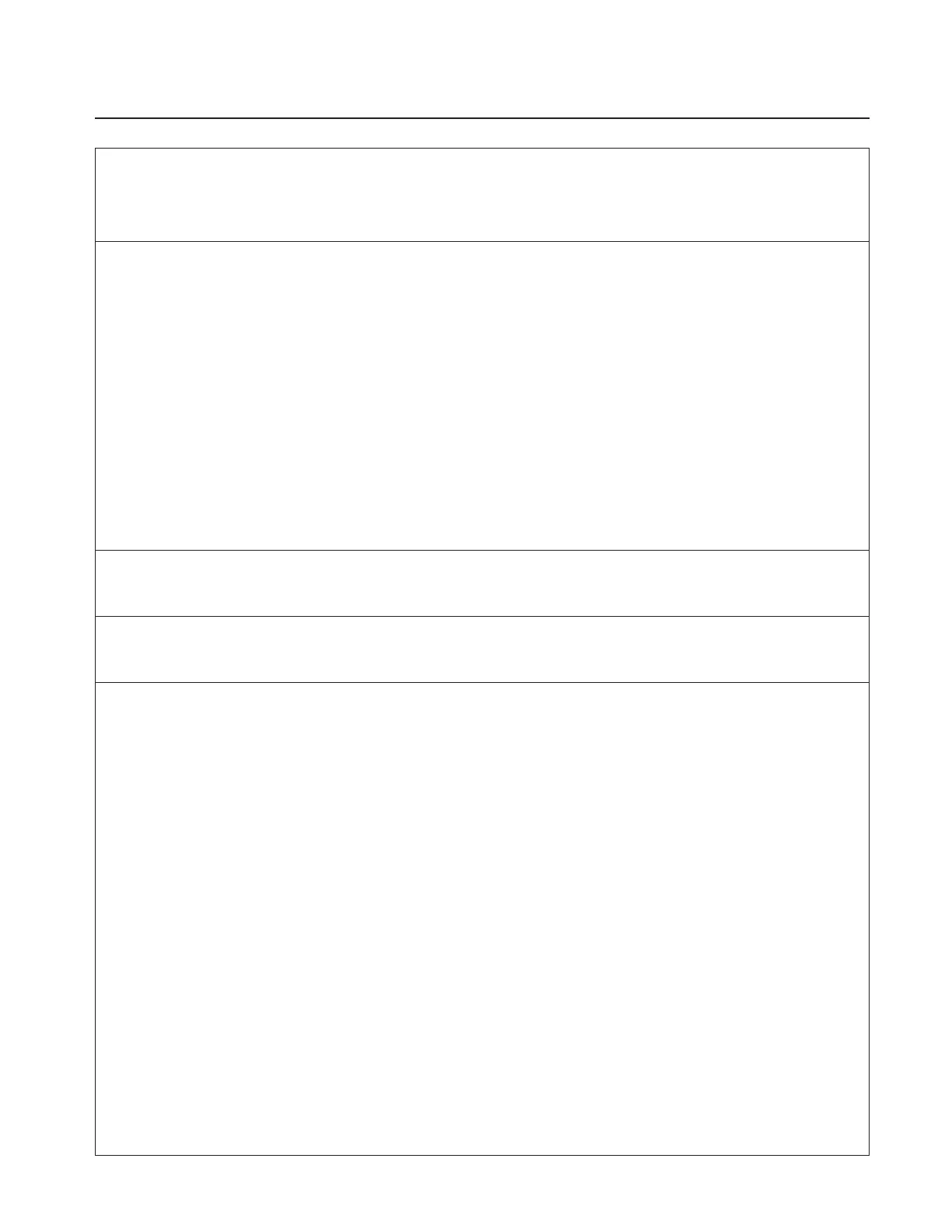

TROUBLESHOOTING GUIDE: MACHINE (Continued)

Problem Possible Cause Solution

1. Belt out of adjustment.

2. Drive or driven conveyor

3. Conveyor table not flat

Readjust by leveling with

5. Roller bushings elongated

Replace bushings (page 31).

Table height adjustment

works improperly.

1. Improper adjustment of

height control.

Readjust height control

(pages 9, 24, 26).

1. Improper V-belt tension.

Increase drive belt

tension.

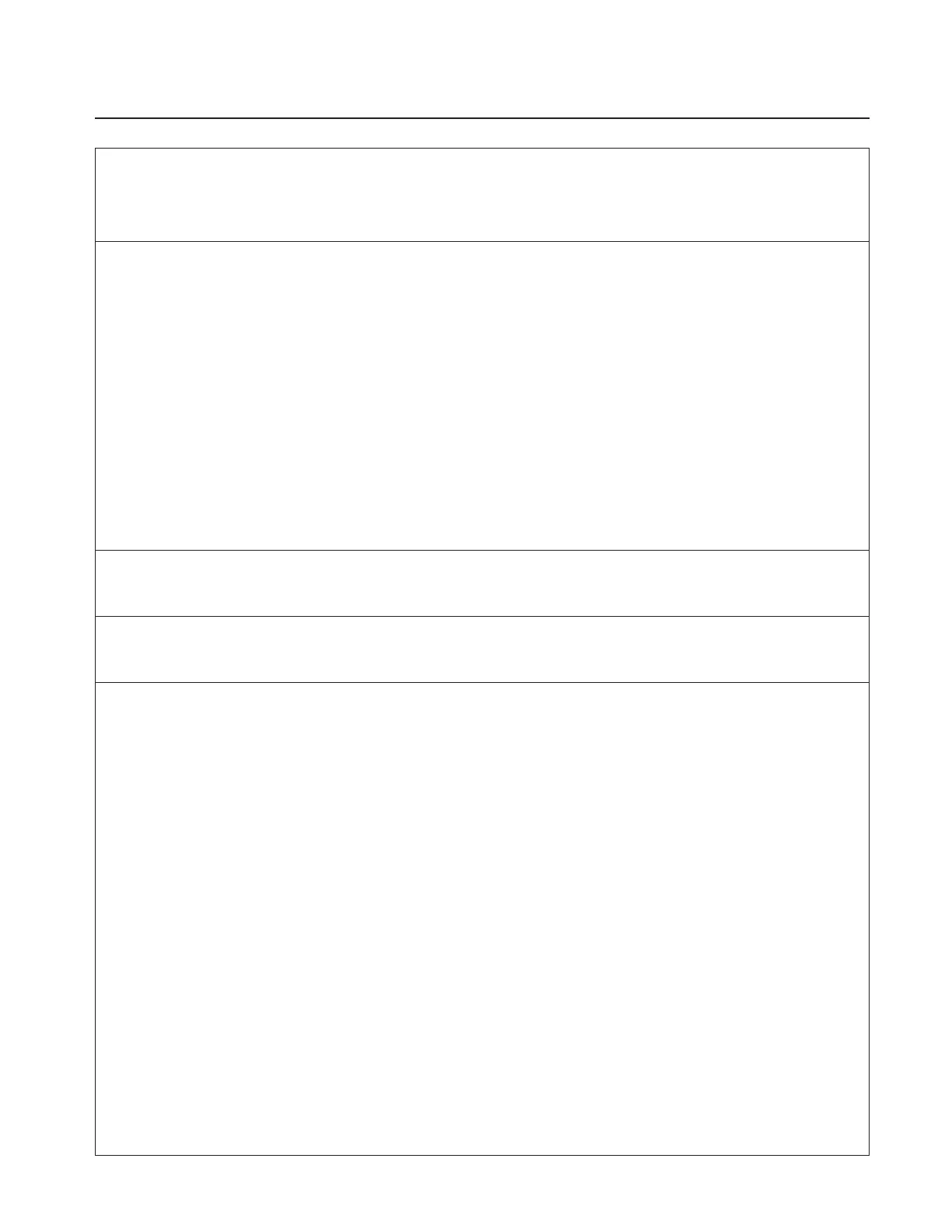

Knocking sound

while running.

1. Bearing out of alignment.

2. V-belt worn.

3. Loose weight in drum.

4.

Pulleys wobbling or

out of round.

5.

Set screws loose in

pulley or bearing.

6. Abrasive fastener on

drum loose (without

abrasive strip in place).

7. Bearing worn.

idler pulley bearings).

Realign bearing (page 33).

Replace V-belt (page 32).

Glue weight back in place.

Replace pulley (page 34)

Retighten or replace set screws.

Insert abrasive paper, or

replace fastener (page 10).

Replace bearing (page 33).

Loading...

Loading...