HANDLE

DRUM

TABLE

HEX NUT &

GEAR

ADJ.

KNOB

SHAFT

INDICATOR

NEEDLE

SCALE

HEX NUT

SERVICING YOUR SUPERMAX

27

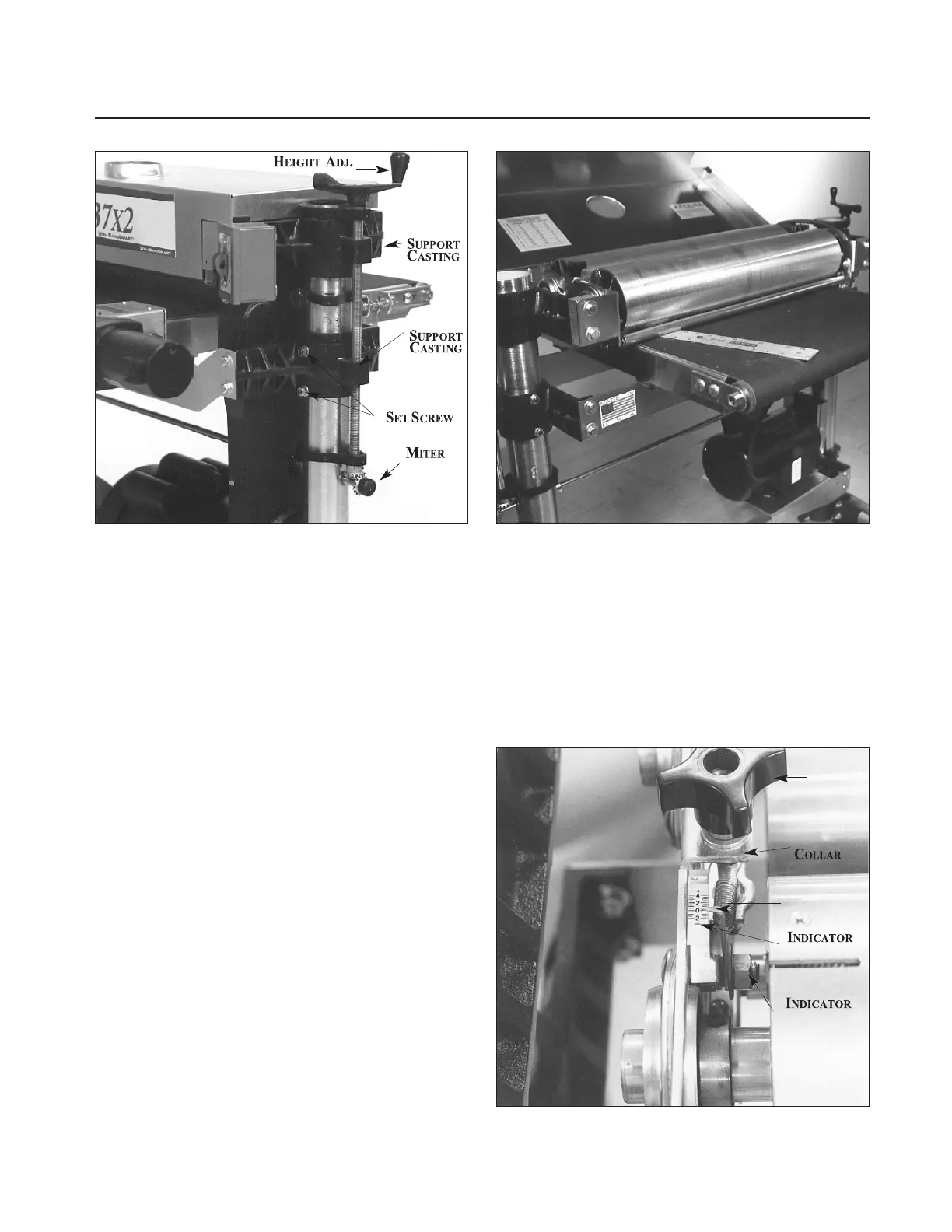

Fig. 25. Adjusting primary drum. Fig. 26. Using thickness gauge during alignment.

ment of the drum (see Adjusting Table Level,

page 7). Note that if only fine adjustment of the

primary drum alignment is required, these adjust-

ment procedures can be used to correct alignment

without relieving V-belt tension or adjusting ten-

sion rollers as described above.

The above procedure is all that is required to

align the drum on a single drum SUPERMAX

sander. If yours is a dual drum machine, follow the

procedure below.

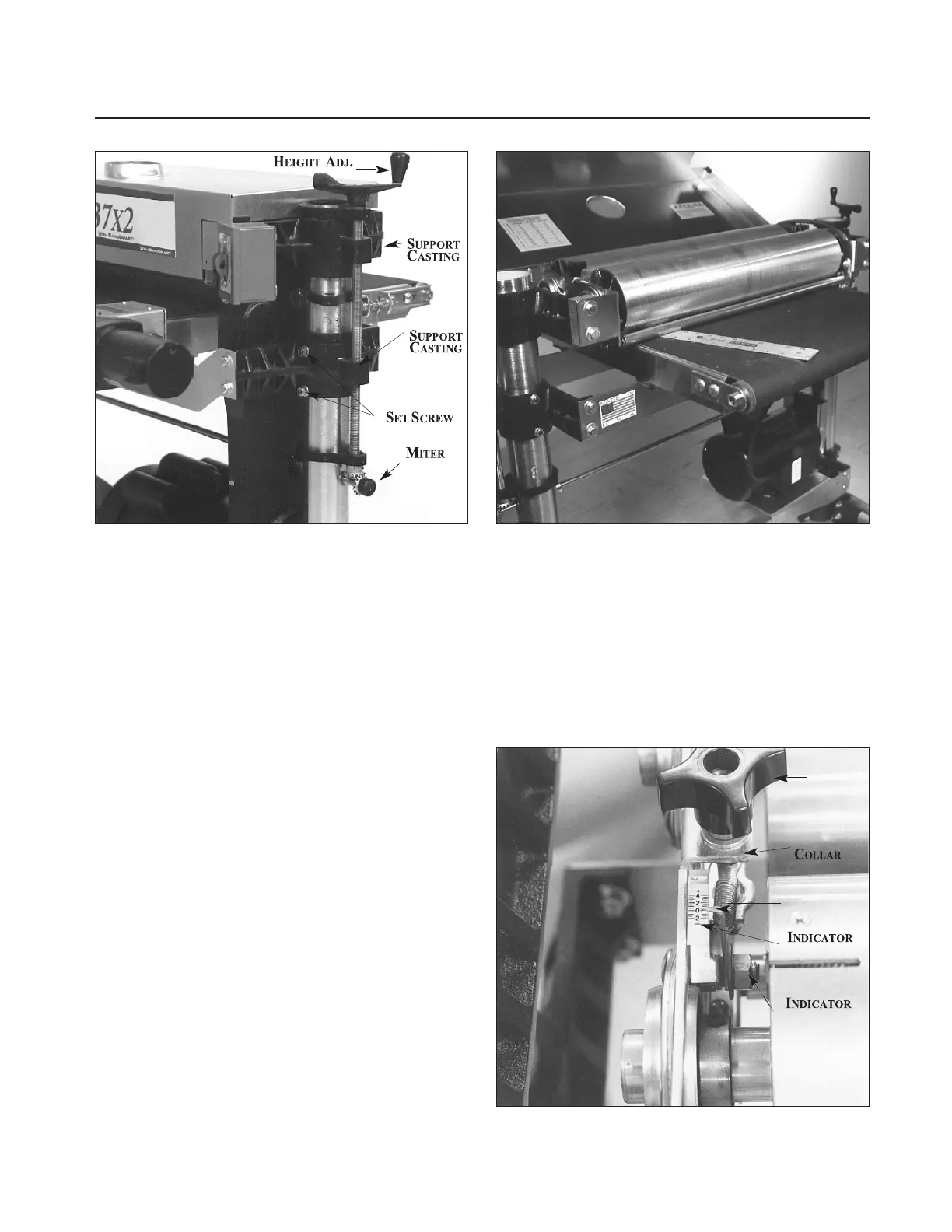

Secondary Drum Alignment. With the primary

drum properly aligned, use the same thickness

gauge and insert it between the secondary drum

and the table from the back side of the machine.

(Again, adjust the contact between the drum and

guide so the drum can barely be turned by hand.)

Measure at both sides of the drum to check that

the secondary drum is parallel to the table. To

adjust the secondary drum alignment, use the

right and left drum adjustment knobs (Fig. 27) to

raise or lower each side of the drum.

At this point both the primary and secondary

drums will be aligned parallel to the table and both

drums will be at the same height above the table.

Set the secondary drum adjustment indicators by

loosening the hex nut (Fig. 27), moving the scale so

that the zero mark is directly under the needle, and

retightening the hex nut. Zero the indicator for

other side of drum in the same manner.

Caution: Do not overtighten the hex nut of the

indicator (Fig. 27). This can flare the brass bush-

ing and render the indicator inoperable. Also, the

secondary drum adjustment knobs should turn

with a slight resistance to avoid any movement

during operation. To adjust knob resistance, turn

the knob clockwise to reveal the set screw on the

Fig. 27. Secondary drum adjustment indicator.

Loading...

Loading...