PERIODIC MAINTENANCE 2-23

CYLINDER COMPRESSION

Cylinder compression :

Standard : 1300 – 1700 kPa

(13 – 17 kg/cm

2

, 185 – 242 psi.)

Max. difference between any other cylinders :

100kPa (1.0 kg/cm

2

, 14 psi.)

NOTE:

Figures shown are guidelines only, not absolute service limits.

Low compression pressure can indicate one or more of follow-

ing :

• Excessively worn cylinder wall

• Worn piston or piston rings

• Stuck piston rings

• Poor seating of valves

• Ruptured or otherwise damaged cylinder head gasket

TEST PROCEDURE

1. Start engine and allow to warm up, then shut engine off.

2. Remove STBD / PORT side covers.(See page 7-2)

3. Remove all spark plugs.

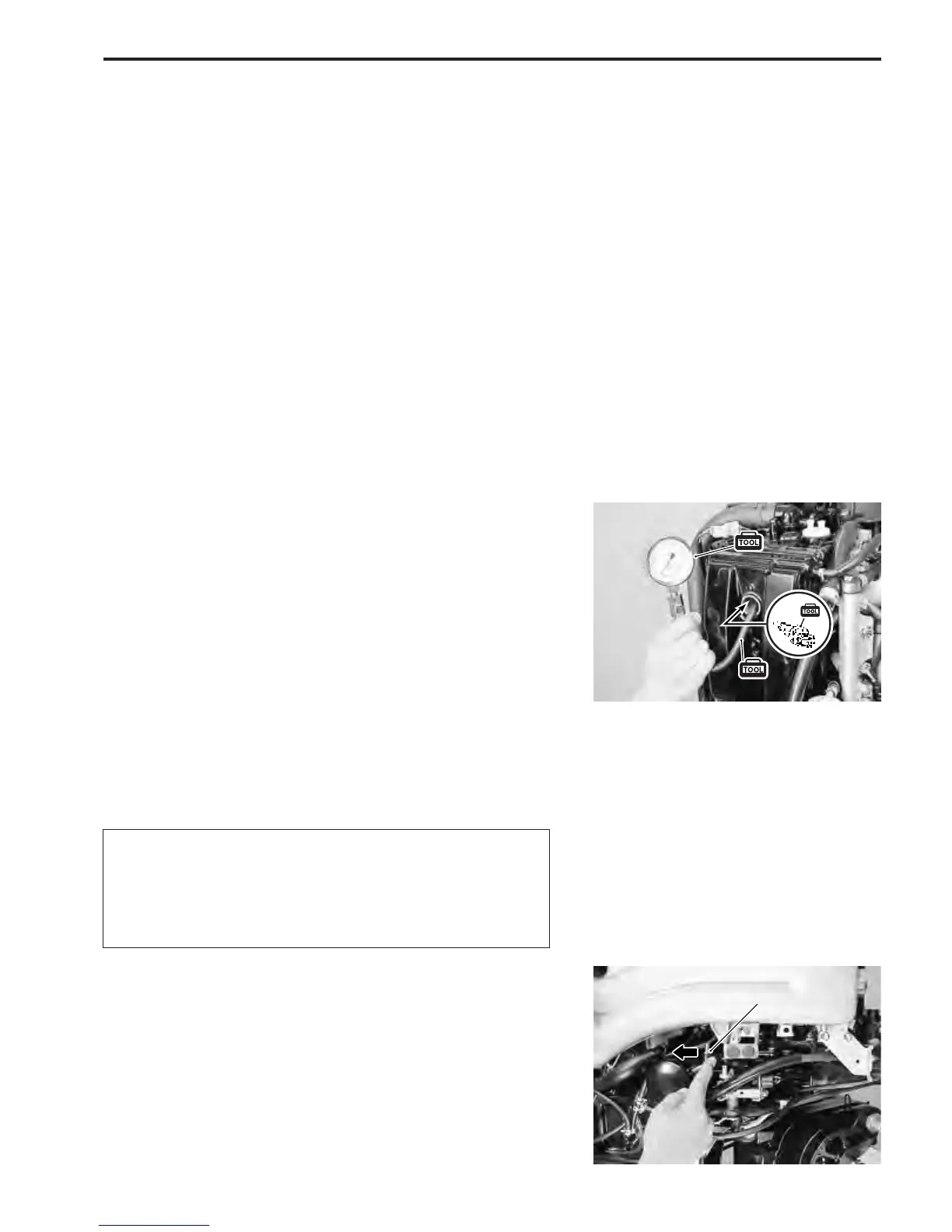

4. Install compression gauge hose attachment into plug hole,

then connect compression gauge hose to gauge hose at-

tachment and compression gauge.

\ 09915-64512 : Compression gauge

09915-64530 : Compression gauge hose

09915-67010 : Compression gauge hose attachment

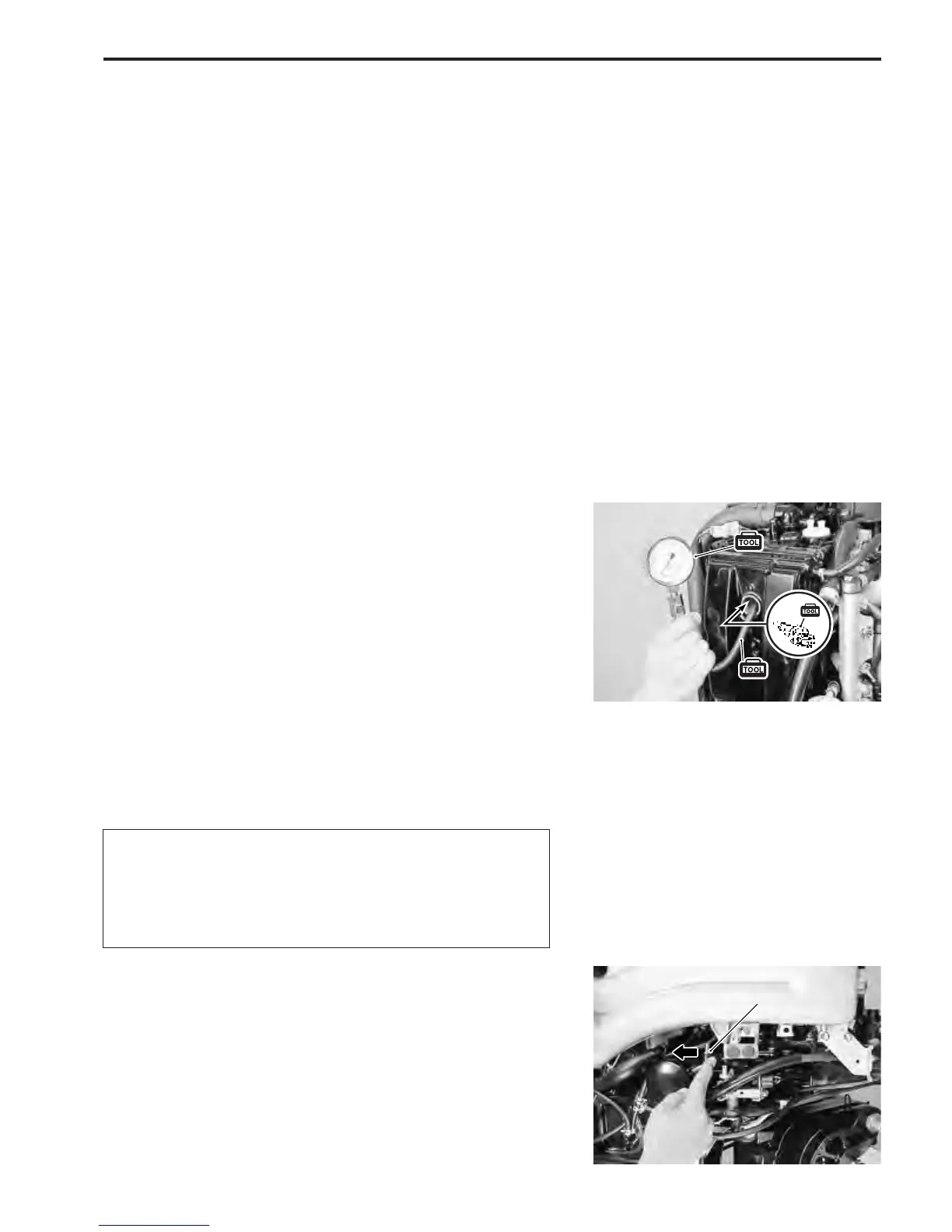

5. Disconnect safety lanyard (switch plate) from emergency

stop switch.

Throttle leverThrottle lever

#

Disconnect the safety lanyard from the emergency stop

switch prior to cranking the engine.

This will prevent any residual fuel discharged from the

cylinders being ignited by a spark discharge from the

spark plug caps.

6. Disconnect remote control throttle cable from throttle lever.

7. Move and hold throttle lever in full-open position.

8. While cranking engine with starter motor, note maximum

compression pressure reading on gauge for each cylinder.

9. Reinstall parts removed earlier. (spark plugs, side covers,

etc.)

Loading...

Loading...