CHANGING A WHEEL

1. Leave caravan hitched to towing vehicle

and ensure handbrake is applied.

2. Lower corner steadies (as safety

measure) on the side that the wheel is

being changed to stabilise the caravan.

3. Use wheel brace to slacken off wheel

nuts on the wheel to be changed.

4. Position jack under the axle at the

appropriate jacking point (see fig. B)

5. Jack up the caravan until the wheel for

removal is just off the ground.

6. Remove the wheel nuts, wheel trims and

remove the wheel.

7. Fit spare wheel and reverse the above

procedure.

Ensure clean, dry mating surfaces and

clean, dry bolt/nut sealing areas.

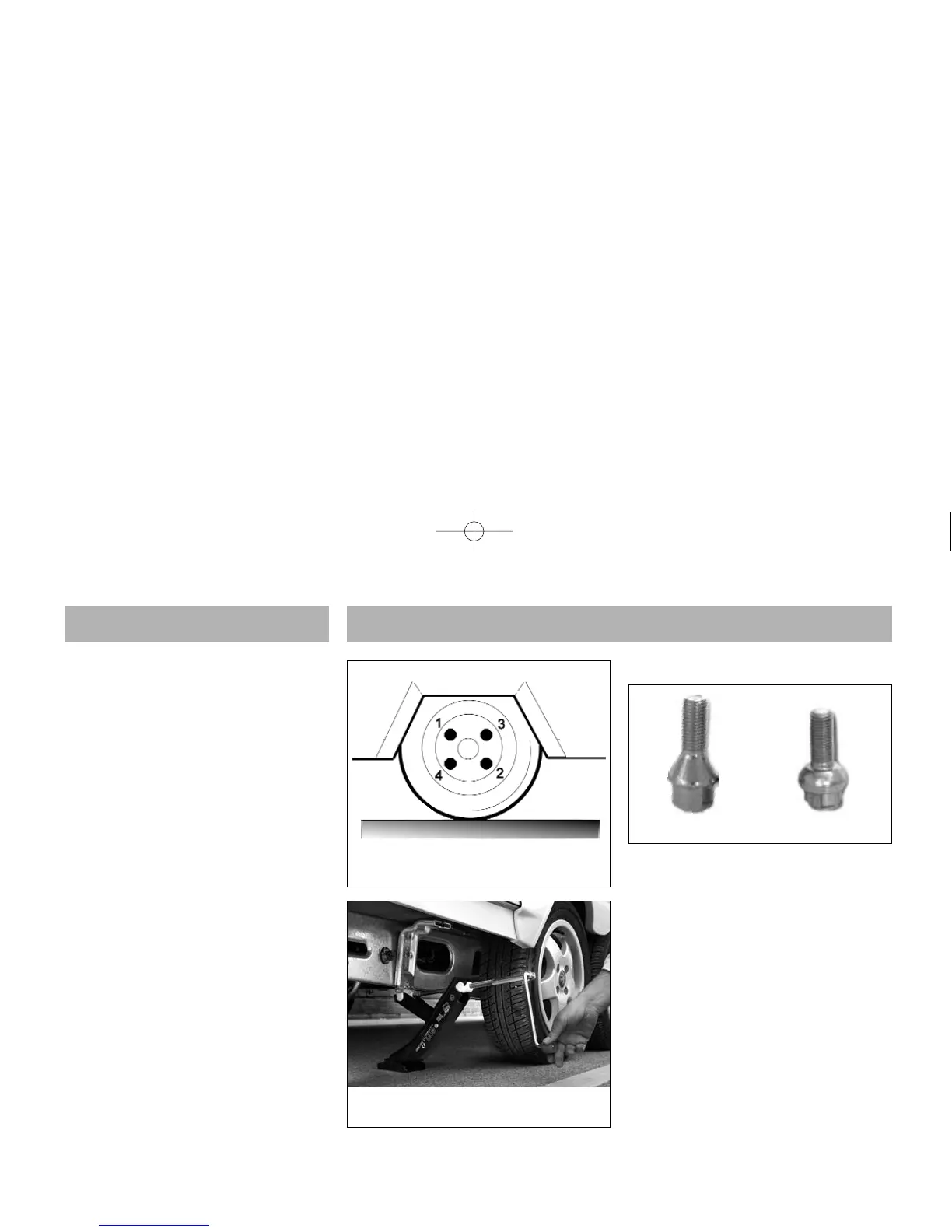

8. Tighten all four/five nuts, according to Fig.

A, to 88Nm (65lb/ft) for steel wheels or

115Nm (85lb/ft) for alloy wheels using a

torque wrench or have checked as soon

as possible.

Ensure the correct wheel fixings are used,

as supplied with your caravan

IMPORTANT

When a wheel has been removed and

replaced the torque of the wheel nuts should

be re-checked after approximately 15 miles

of running. (See 8 above).

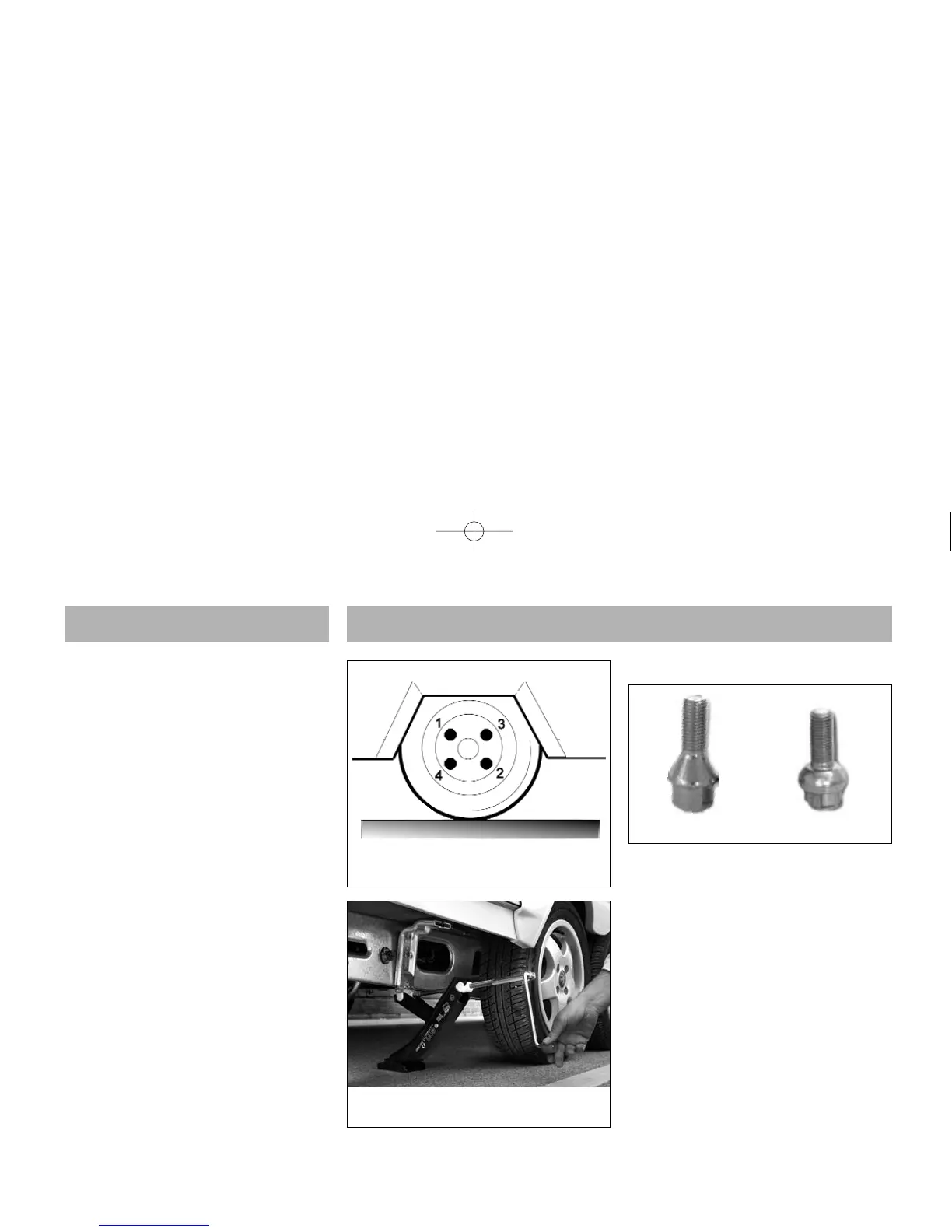

PLEASE NOTE DIFFERENT BOLT TYPES

Conical seated wheel bolts are suitable for

14” and 15” alloy and 14” steel spare wheel

use only. However Spherical seated wheel

bolts must be used on the 15” steel spare

wheel (Challenger and Cameo single axle).

Spherical seated bolts must not be used on

any 14” wheel or 15” alloy wheel this is due

to the machined seating on the wheel rim.

MODELS AFFECTED: CAMEO SINGLE

AXLES AND CHALLENGER RANGE.

SPHERICAL BOLTS ARE TIE WRAPPED TO

THE SPARE WHEEL.

Fig. A Wheel Nut Tightening

Conical Spherical

Fig. B Scissor Jack

The Towing Code

18

Loading...

Loading...