Maintenance

149

AXLE TYPES

Safety Precautions

No welding is permitted on AL-KO Axles

It is important that the wheel and hub/ brake

drum are compatible. This mean that the

PCD, wheelbolts and inset must all be

compatible with both the hub/brake drum

and the wheel rim.

Particular attention must be paid to the

recommended torque figures for the

wheelbolts (see pg 18).

The axle type details shown on axle type

plates must not be obscured or made

illegible by application of any additional

surface finish.

Operating Instructions

Service Brake

When the towing vehicle is braking or

travelling down hill, the overrun device shaft

is pushed in (dependent on the magnitude of

the thrust on the shaft) and presses on the

overrun lever. This acts on the bowden

cables and expander mechanism, which in

turn expands the brake shoes applying the

wheel brakes.

Hand Brake

With the gas strut version, pull the

handbrake lever until upright. With the spring

cylinder version, pull the handbrake lever

right up to the last tooth. The caravan is then

braked.

IMPORTANT NOTE

Please note that with the handbrake fully

applied, the caravan/trailer is able to move

backwards by 25 cms until the spring

cylinder/gas spring takes effect.

Maintenance and Cleaning

Maintenance of Euro-Plus/Euro-Compact

and Euro-Delta.

The above semi-trailing axles come fitted

with maintenance free wheel bearings

(greased and sealed for life) and no

adjustment is necessary.

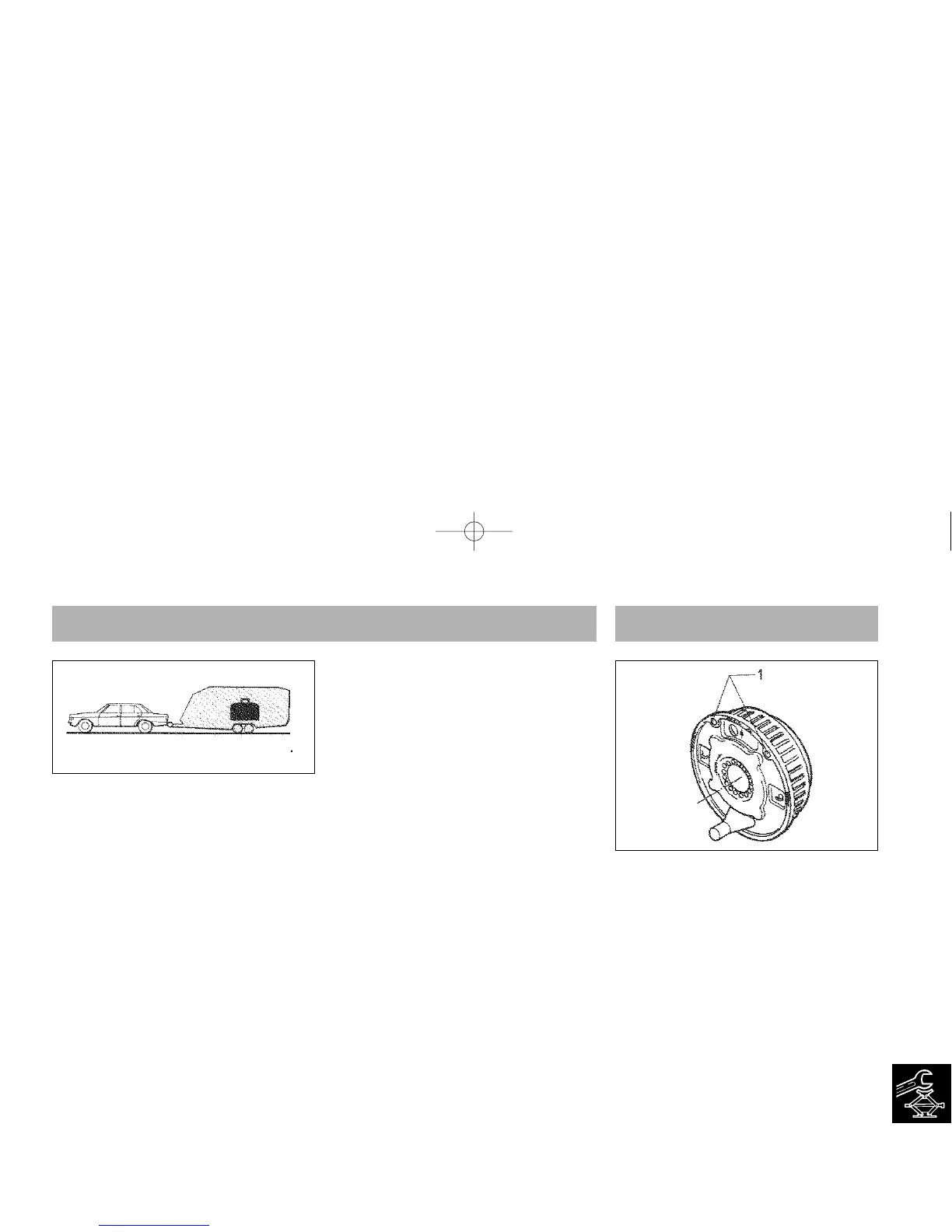

NOTE: The hub bearing is not protected

against water ingress. Check wheel brake

linings for wear every 10,000 kilometers or

every 12 months via the inspection hole

(Fig. 5/Item 1). Adjust if necessary. Where

continuous travel in hilly regions or high

mileage is experienced, earlier inspection

and adjustment may be necessary.

NOTE: The flanged hub-nut, located under

the dust cap, used to keep the brake drum

in situ, is a ONE-SHOT NUT (ie. must only

be used once). If removed it must be

replaced with a NEW flanged nut - torqued

to 290 ± 10 Nm (214+/1 7.5 lbs/ft). A small

amount of special mineral grease, available

from AL-KO must be applied to stub axle

thread prior to fitting the new flanged nut.

After fitting excess grease must be removed

with white sprit.

The rear hexagon cap head bolt located

under the black plastic cap MUST NOT BE

DISTURBED under any circumstance.

Interference with this nut will result in

immediate tyre wear and damage to the

braking system and WILL INVALIDATE ALL

WARRANTIES. Should the rear nut

accidentally be disturbed then the complete

axle must be returned to AL-KO for resetting

of the toe-in and camber.

Fig. 4

Fig. 5

Loading...

Loading...