N770-06-00 2 I56-509-01

not responsible for devices that have been improperly in-

stalled, tested or maintained.

1. Mount the detector where there is adequate clearance

for installation and removal and a clear view of it for in-

spection. See Figure 1 for mounting dimensions.

2. Locate to protect from damage, 6-7 feet above the floor.

3. On horizontal runs, position the detector on top of the

pipe or on the side. Do not mount it upside down.

4. Mount detector at least 6 inches from a fitting which

changes the direction of the water flow.

5. BE SURE DIRECTION-OF-FLOW ARROW MATCHES AC-

TUAL DIRECTION OF FLOW IN THE PIPE.

Mounting Instructions

1. This WFDTNR waterflow detector is designed to fit only

the appropriate tee fitting.

NOTE: Leg of tee perpendicular to flow of water must

have a 1" NPT thread. Do not use a reducer to

achieve the correct thread size. Failure to follow

this instruction will result in failure of the detector

to report a waterflow condition.

2. WFDT units are shipped without the paddles mounted to

the actuator. Select the correct size paddle for the tee be-

ing used the appropriate nominal pipe diameter size is

molded on the surface of the paddles). Align hole on

stem of paddle with hole on actuator lever. Fasten to-

gether using a #4-40 x

1

/

4

" fillister head screw supplied

in bag assembly. See Figure 2. Use only the screw pro-

vided with the WFDTNR. Drive screw head through hole

in paddle until it seats firmly to actuator lever surface.

No washer is required. For paddle replacement refer to

Maintenance section.

3. Thread detector onto tee fitting and tighten with

A78-2111-00

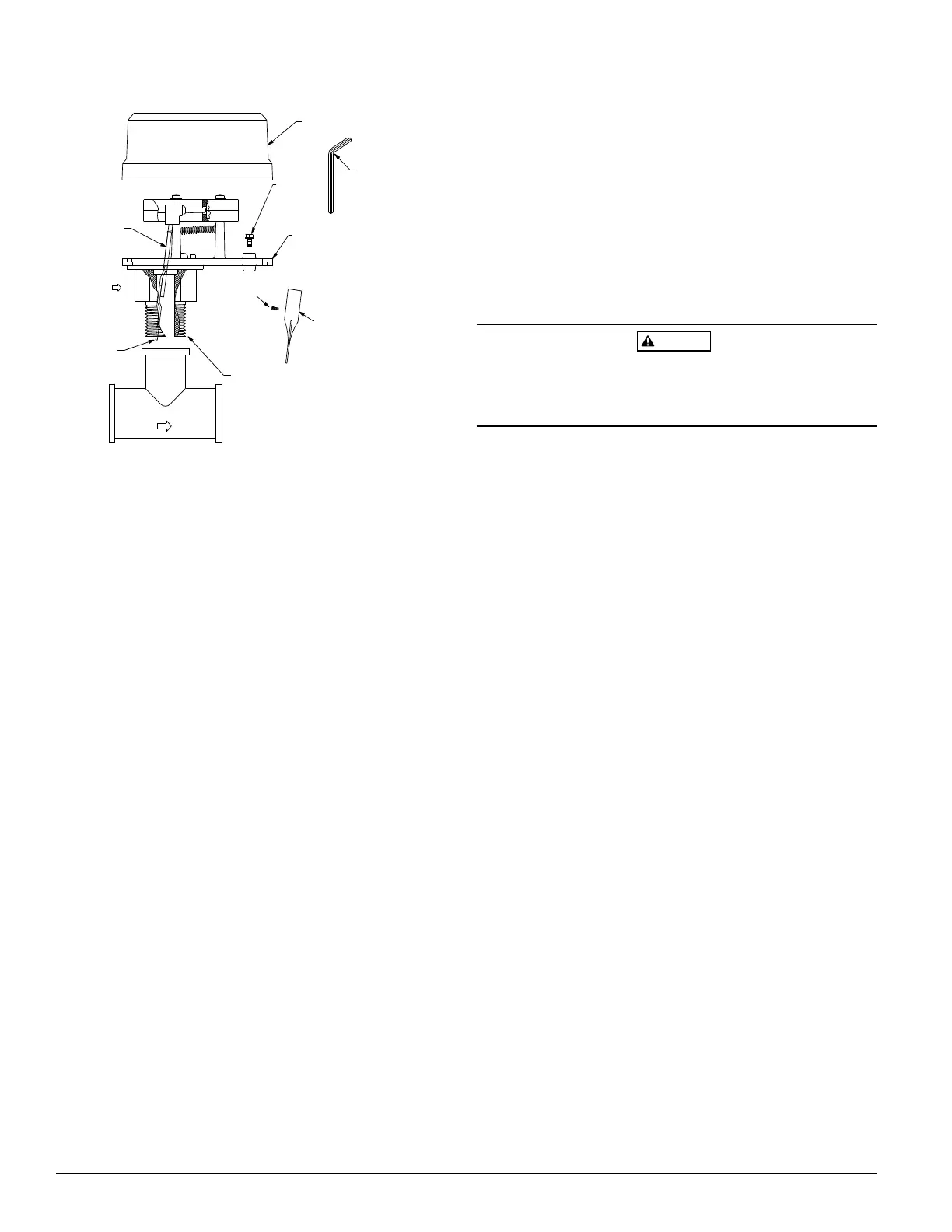

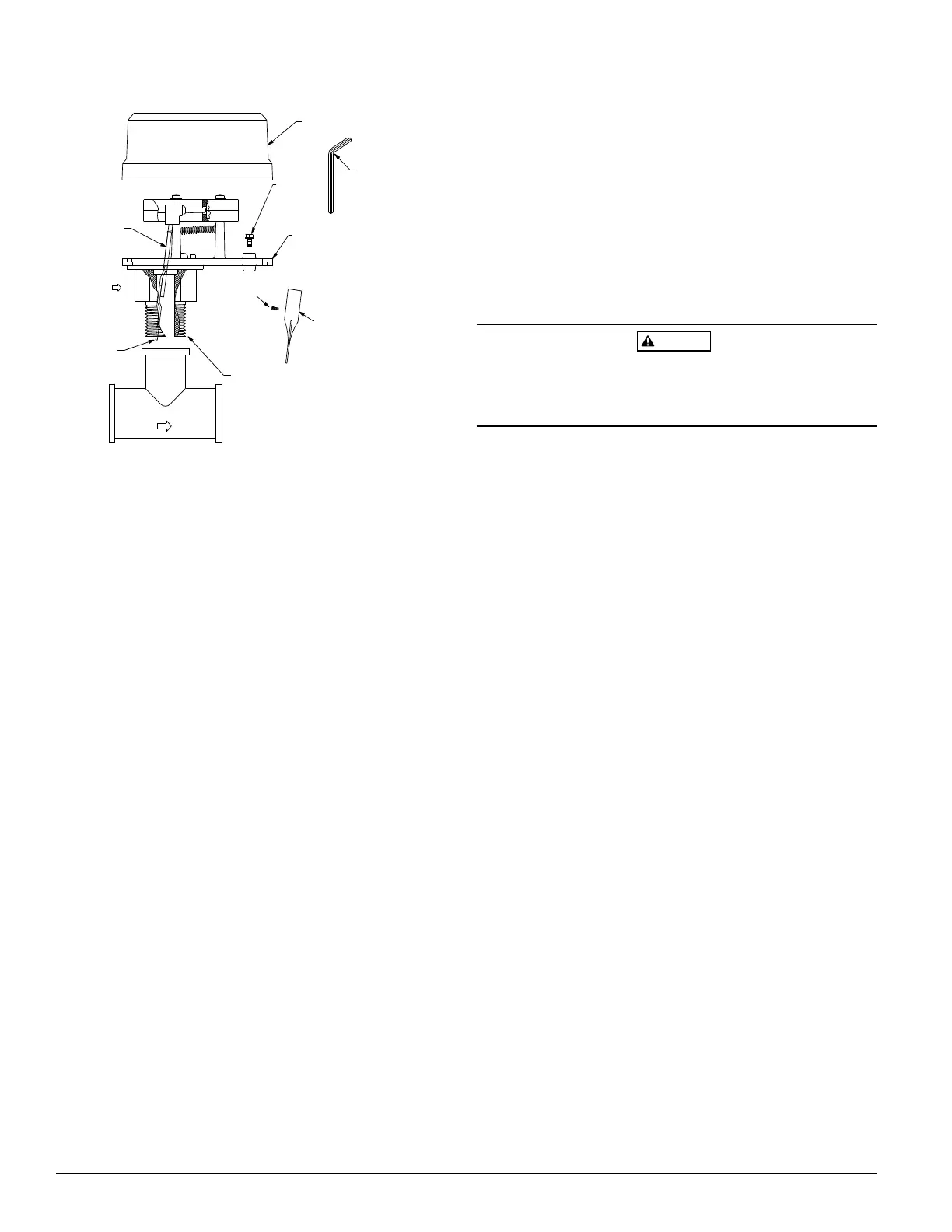

Figure 2. Assembly diagram:

COVER

GROUND

SCREW

(GREEN)

MOUNTING

PLATE

TAMPER PROOF

WRENCH (P/N WFDW)

PADDLE

FILLISTER

HEAD SCREW

1" NPT THREAD

WATER FLOW

ACTUATOR

ASSEMBLY

FLOW

ACTUATOR

LEVER

wrench. Use of thread sealant or tape is recommended.

Use height gage (located at end of paddle tee) to ensure

proper depth of detector on tee fitting. See Figure 1.

Height gage must fit between top of tee fitting and under

side of hex tee adapter. A gap between gage and tee

adapter is acceptable. When correctly installed, the de-

tector must face in the proper direction of waterflow and

be aligned with the pipe.

4. Remove the plastic cover with the tamper proof wrench

provided. Move the actuator lever back and forth to

check for binding. If the vane binds, remove the detector

and correct the problem before proceeding.

CAUTION

Be sure the direction-of-flow arrow points in the correct di-

rection, otherwise a waterflow condition will go unre-

ported. See Figure 2.

Operational Testing

Always notify a central station monitoring waterflow

alarms before repairing, maintaining, or testing waterflow

alarm devices.

1. Fill the sprinkler and check for leaks around the

WFDTNR. If it leaks, check to see that the fittings are

tight. If leak persists, drain the system and remove the

detector (see removal instructions under Maintenance).

Check for damaged threads or cracked fitting. Reinstall

detector and check again for leaks. Do not proceed until

all leaks have been stopped.

2. With cover removed, connect an ohmmeter or continu-

ity tester across (COM and B) terminal switch contacts.

The ohmmeter should show an open circuit, no continu-

ity (when the red switch buttons are depressed).

3. Deflect the actuator lever to release the switch buttons.

The ohmmeter or continuity tester should show a short

circuit when the switch buttons are released.

4. Open the inspector's test valve to allow the detector to

indicate a flow condition. The detector should remain

activated until the inspector's test valve is closed. Air

pockets in the sprinkler system may prevent the detector

from firing immediately.

5. Replace the cover and tighten the security screws with

the tamper proof wrench. Store wrench is a secure place.

Field Wiring

1. The WFDT has two SPDT switches. Switch contacts

(COM and B) are closed when water is flowing and open

when water is not flowing. Connect the switches as

shown in Figure 3 depending on the application.

2. When connected to a listed sprinkler/fire alarm control

panel, the initiating circuit must be non-silenceable.

Technical Manuals Online! - http://www.tech-man.com

Loading...

Loading...