N770-04-00 1 I56-393-05

OSY2 Gate Valve

Supervisory Switch

INSTALLATION AND MAINTENANCE INSTRUCTIONS

A Division of Pittway

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

Important

Please Read Carefully And Save

This manual contains important information about the in-

stallation and operation of supervisory switches. These in-

structions apply to System Sensor switches for outside

screw and yoke valves only. Read all instructions carefully

before beginning installation.

WARNING

Do NOT use this switch in explosive or potentially explo-

sive atmospheres.

Do NOT leave unused wires exposed.

All supervisory switch installations must comply with local

codes and ordinances and the requirements of the authority

having jurisdiction. Additional information is available in

National Fire Protection Association standards NFPA 13,

13D, 13R, 71, and 72.

General Installation Considerations

The OSY2 Supervisory Switch can be mounted on open

yoke valves between

1

/2" and 12" in diameter in the posi-

tions shown in Figure 1 only. If the switch is installed with

the actuator pointing upward, water may leak into the inte-

rior of the switch. Therefore, do NOT install the OSY2

with its actuating lever pointing upward.

All OSY2 models are equipped with a ground screw inside

the switch housing near the conduit exit hole for those ap-

plications where grounding is required.

Narrow Yoke Valves

As Figure 2 suggests, installing the valve with mounting

bolts inside the yoke is recommended. However, some

valves may have yokes that are too narrow for this arrange-

Specifications

Contact Ratings: 10 A @ 125/250 VAC

2.5 A @ 24 VDC

Dimensions: 5

3

/4"H X 3

1

/2"W X 3

1

/4"L

Maximum Stem Extension: 2

5

/8"

Minimum Stem Extension:

5

/8"

Bracket Span: 6

3

/4"

Operating Temperature Range: 32° - 120°F (0° - 49°C)

Shipping Weight: 2

3

/4 lb.

ment. If this is the case, the bolts can be positioned on the

outside of the yoke.

Limited Clearance Valves

The OSY2 mounting bracket fits most of the open yoke

valves used in fire protection systems. However, some of

these valves, especially those less than 1

1

/2" in diameter,

have irregularly shaped yokes or such limited clearances

that the clamping bar cannot be installed properly and/or it

causes the valve to bind. If this is the case, the use of the

supplied J-bolts is required to attach the OSY2 to the valve

(see J-Bolt Detail, Figure 2).

Installation Procedure

See Figures 2 and 3, as required, while performing the pro-

cedure that follows.

Perform step 1 on valves 1

1

/2" in diameter and smaller

only. Proceed directly to step 2 if the switch is being in-

stalled on a valve larger than 1

1

/2" in diameter.

1. Remove and discard the two C-clips and roller from the

actuating lever.

2. Set the valve to its fully open position. Remove the OSY2

Supervisory Switch from the carton and adjust the posi-

tion of the retaining washers to provide sufficient bolt

length for the yoke thickness of the valve.

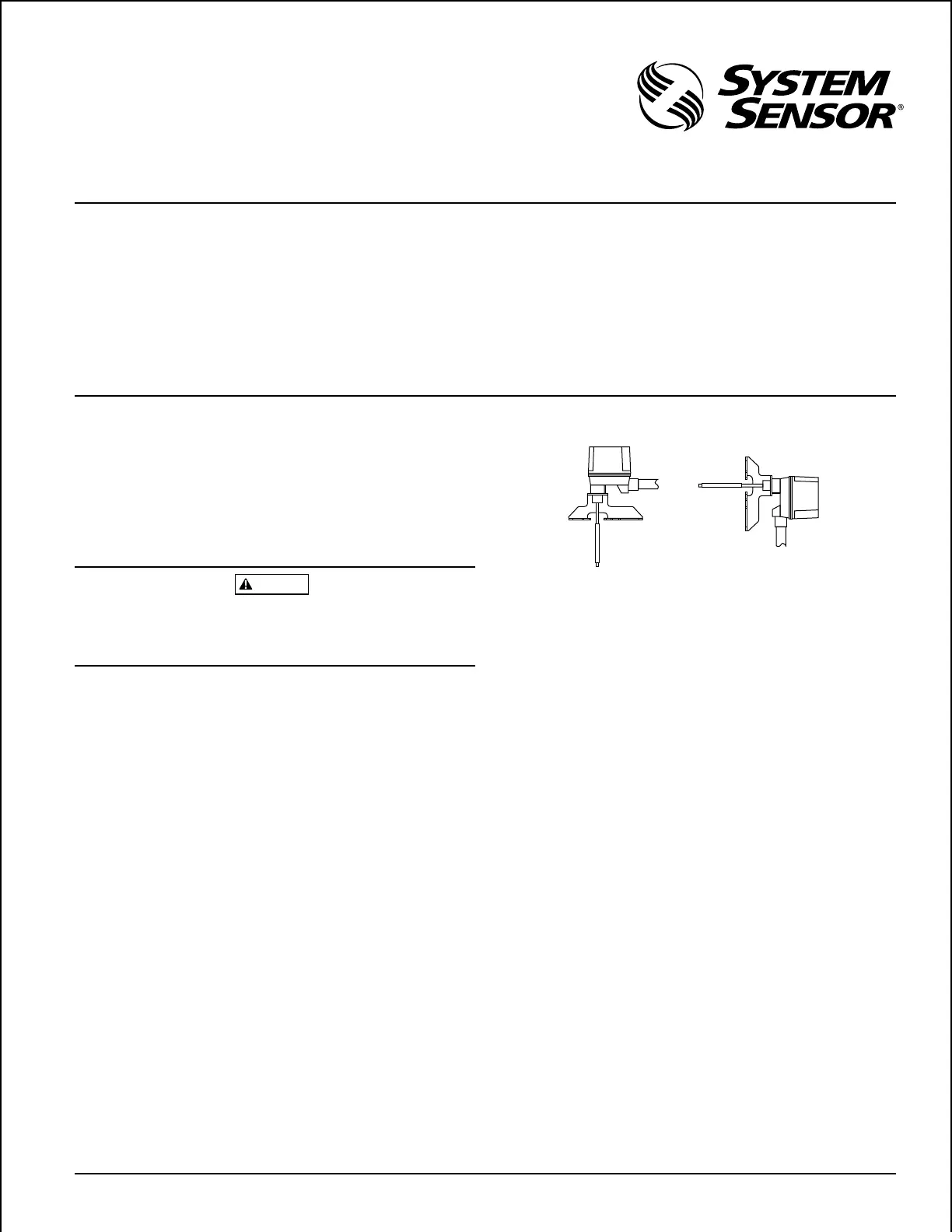

Figure 1:

ACTUATOR

VERTICAL (DOWN)

ACTUATOR

HORIZONTAL

Technical Manuals Online! - http://www.tech-man.com

Loading...

Loading...