24

6 - SyScroll Air CO/HP Control

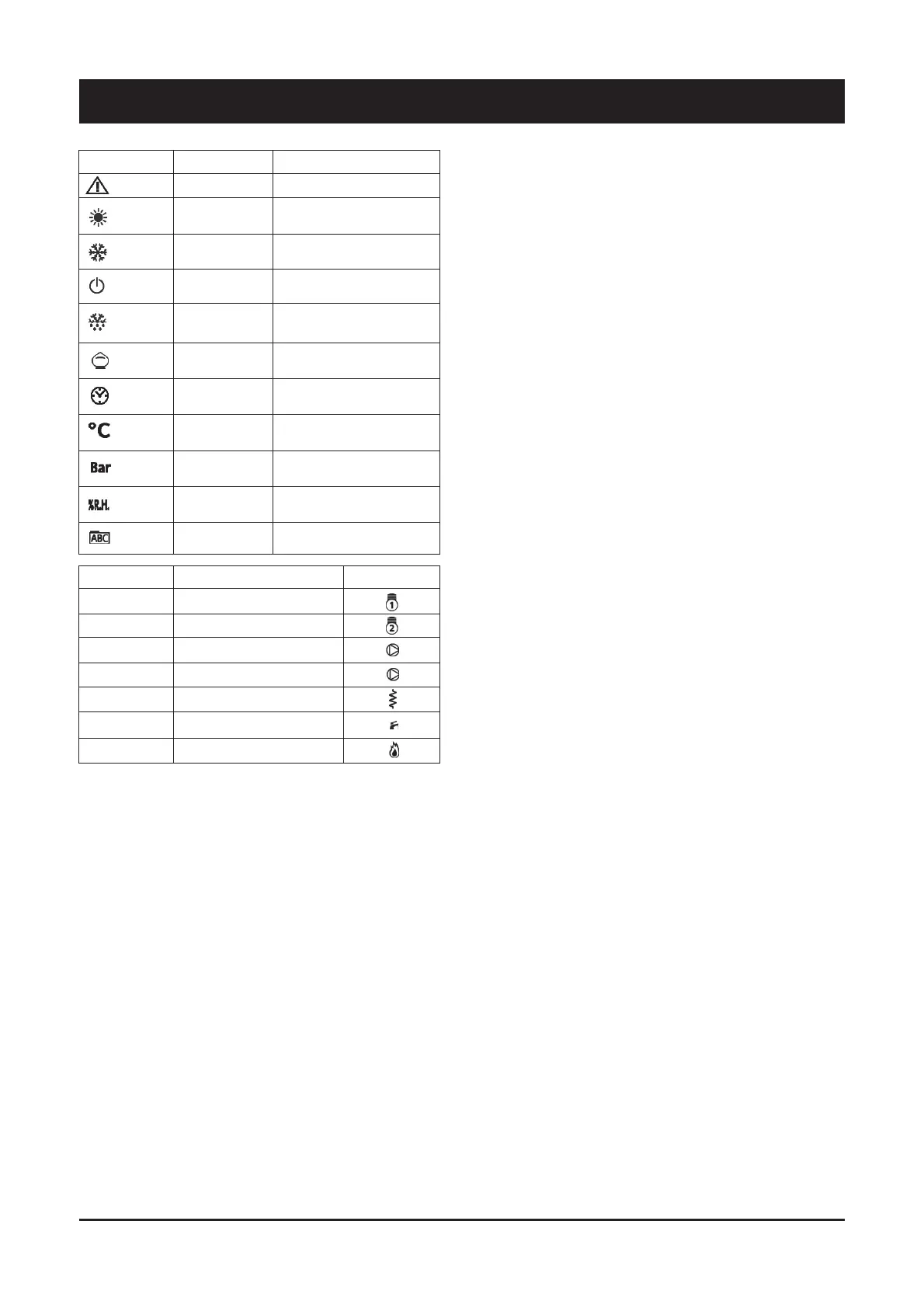

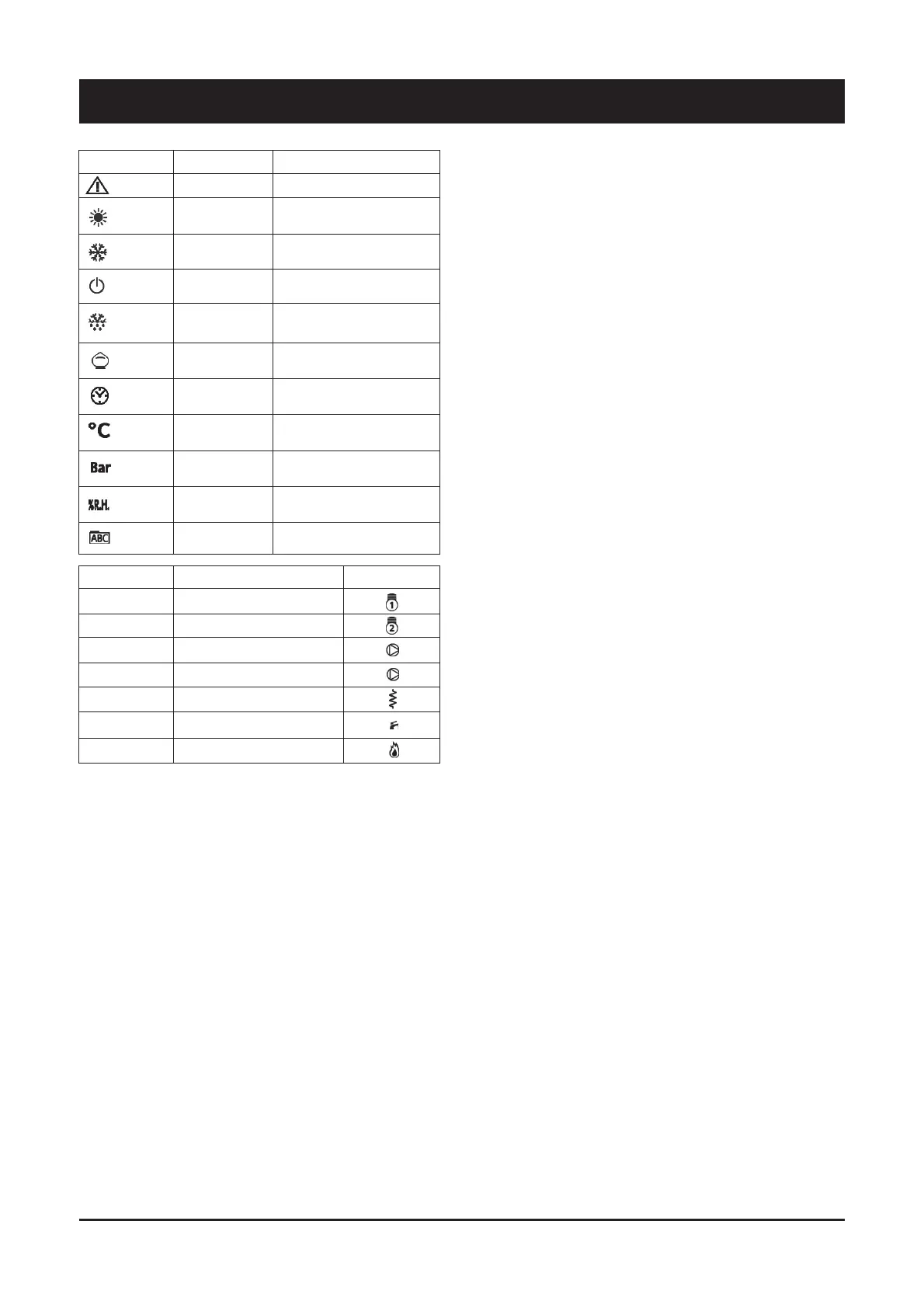

ICON / COLOR

LED N°*

STEADY ICON

DESCRIPTION

BLINKING ICON

ICON

- Alarm ON

First capacity step

Second capacity step

Primary circuit pump

Source circuit pump

Electrical heater

Sanitary hot water valve / pump

Boiler

/ RED

1

2

3

4

5

6

7

/ GREEN

/ GREEN

/ GREEN

/ GREEN

/ GREEN

/ RED

/ RED

/ RED

/ RED

/ RED

- Mode: HEATING

- Current HR

- Time slots activ.

- Mode: COOLING

/

/

/

- Mode: STAND-BY

- Configurable

Not used

Menu surf

- Alarm QUIT

- Antifreeze+Heat pump ON

- Heating mode by remote

- HR setting

- Time slots programming

- Cooling mode by remote

/

/

/

- Stand-by mode by remote

- Configurable

Not used

/

6.3 Folder structure

Folder structure is composed of totally four menus

1) Main display¤used to set what to display without acting on any

key

– Ai¤analogue input (temperature, pressure)

– rtC¤room time clock

– SetP¤standard set-point

– SetR¤corrected set-point (according to climatic correction,

etc.)

2) Operating mode¤used to set operating mode

– StbY¤stand-by

– HEAT¤heating

– COOL¤cooling

– AS¤sanitary hot water

3) Status¤used to show resources values

– Ai (AIL/AIE/Air)¤analogue inputs (main board / expansion

board / remote terminal)

– di (diL/diE)¤digital inputs (main board / expansion board)

– AO (AOL/AOE) ¤ analogue outputs (main board/expansion

board)

– CL (HOUr/dAtE/YEAr)¤clock

– AL (Er00¤Er98)¤alarms

– SP¤standard set-point

– Sr ¤ corrected set-point (according to climatic correction,

etc.)

4) Program¤define parameters, functions, password and to display

alarm log

6.4 Menu structure

“Program” menu is composed of totally four folders

1) Parameters¤change unit parameters

2) Functions¤manual operations (switch ON / switch OFF, alarm

quit, historic alarm delete, multi function key use)

3) Password¤define visibility levels for parameters/folders

4) Alarm log¤display alarm log

Parameter folder gives access to following sub-folders

– CL/CE/Cr/CF¤configure device I/O (L¤local; E¤expansion; r

¤remote; F¤serial)

DQDORJXH LQSXWV W\SH RI SUREH UDQJH GLIIHUHQWLDO ORJLF

function)

GLJLWDOLQSXWVORJLFIXQFWLRQ

GLJLWDORXWSXWVORJLFIXQFWLRQ

DQDORJXHRXWSXWVUDQJH

VHULDOFRQILJXUDWLRQFRPPXQLFDWLRQSDUDPHWHUV

– TR¤define thermoregulation parameters

VHWSRLQWPD[PLQK\VWHUHVLV

W\SHSURSRUWLRQDOGLIIHUHQWLDO

SUREHVHOHFWLRQ

– ST¤define operating status

FRROLQJRQO\

KHDWLQJRQO\

VFRROLQJDQGKHDWLQJ

FKDQJHRYHU

– CP¤configure compressor parameters (type/number/timing)

– PI¤define primary circuit / parameters / functions

RSHUDWLQJPRGHGLVDEOHDOZD\V2121LIFRPSUHVVRU21

GLJLWDODQDORJXHFRQWURO

DQWLVWLFNLQJ

DQWLIUHH]H

– BR ¤ control the parameters for an additional step for heating

and for sanitary hot water integration (boiler)

RSHUDWLQJPRGHGLVDEOHGLIIHUHQWLDO¤ fixed or in function of

outdoor air temperature)

VHWSRLQWK\VWHUHVLV

– DS¤define set-point offset (dynamic set-point) depending on

DQDORJXHLQSXW«9«9«9«P$

RXWGRRUDLUWHPSHUDWXUH

URRPWHPSHUDWXUH

– AD¤simulate an electronic inertial accumulator, acting on set-

point and hysteresis (adaptive function), by confronting minimum

/ effective ON-OFF time

– AS¤define sanitary hot water management parameters

RSHUDWLQJPRGHGLVDEOHVDQLWDU\KRWZDWHUYDOYHUHVLVWDQFH

/ pump)

VHWSRLQWK\VWHUHVLV

DQWLOHJLRQHOODIXQFWLRQ

– HP¤define heat pump block management parameters

RXWGRRUDLUWHPSHUDWXUH

WKHUPRUHJXODWLRQWHPSHUDWXUH

GLJLWDOLQSXW

– PL ¤ define capacity limitation to protect the unit (high/low T,

high/low P)

– TE ¤ define time slots management (different operating daily

profiles)

– AL¤define alarms management (automatic / manual reset, by-

pass time, sampling)

Loading...

Loading...