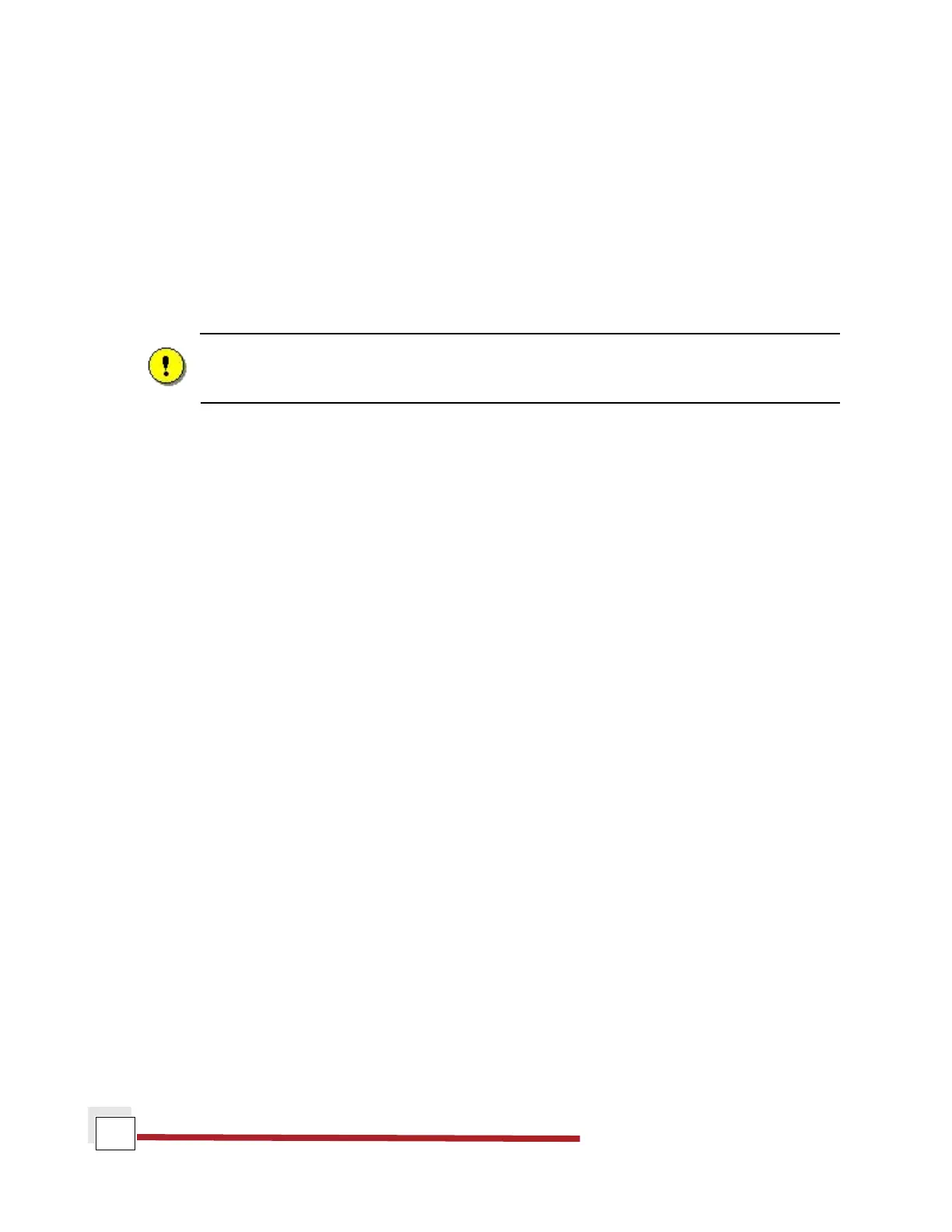

DSC Q Series Getting Started Guide

38

Cooling Gas Line

The Cooling Gas port is used with the Finned Air Cooling System (FACS), Refrigerated Cooling System (RCS),

or the Liquid Nitrogen Cooling System (LNCS). The FACS requires a source of compressed air, while the RCS

and LNCS require a source of dry nitrogen for the cooling gas line. Follow these instructions to connect the

appropriate cooling gas line.

1. Locate the fitting, a 1/4-inch compression fitting or 1/4-inch Legris fitting on the right rear of the DSC,

marked with a 830 kPa gauge (120 psig) warning label.

2. Make sure your gas source is regulated between 170 to 830 kPa gauge (25 to 120 psig) when using the FACS.

For details on the pressure required for the RCS and LNCS, see the appropriate Getting Started Guide.

CAUTION: The Cooling Gas line feeds into a pressure-regulated valve that is set to 170

kPa gauge (25 psig). The source pressure setting should not go below this value.

3. Connect the 1/4-inch O.D. tubing from the gas source (compressed air for the FACS or dry nitrogen for the

RCS and LNCS) to the Cooling Gas fitting.

Base Purge Line

A base purge is required when the Quench Cooling Accessory (QCA), Refrigerated Cooling System (RCS), or

the Liquid Nitrogen Cooling System (LNCS) are used.

1. Locate the Base Purge port.

2. Make sure that the pressure of your gas source is regulated between 100 and 140 kPa gauge (15 and 20 psig).

Dry nitrogen is the recommended gas.

3. Connect the gas line to the Base Purge port using 1/8-inch O.D. tubing. Teflon® TFE tubing is recommended.

An orifice in the instrument will automatically regulate the flow rate (300 to 350 mL/min) for proper operation.

Loading...

Loading...