112

MAINTENANCE

After First 50 Hours (New Machines Only)

Adjustment

1.Tilt up the platform.

Refer to page 134 “Tilting Up the Platform”.

2.Loosen the adjustment bolt (5) and locking

nut (6).

3.Using a lever (7), move the alternator (8)

and adjust the slack.

4.Tighten the adjustment bolt (5) and locking

nut (6).

Inspecting and Adjusting the Fan Belt

Stop the engine and allow the machine

to cool down before performing

inspection and maintenance.

¡The engine, muffler, radiator, hydraulic

lines, sliding parts and many other

parts of the machine are hot directly

after the engine is stopped. Touching

these parts will cause burns.

Inspection

1.Open the engine hood.

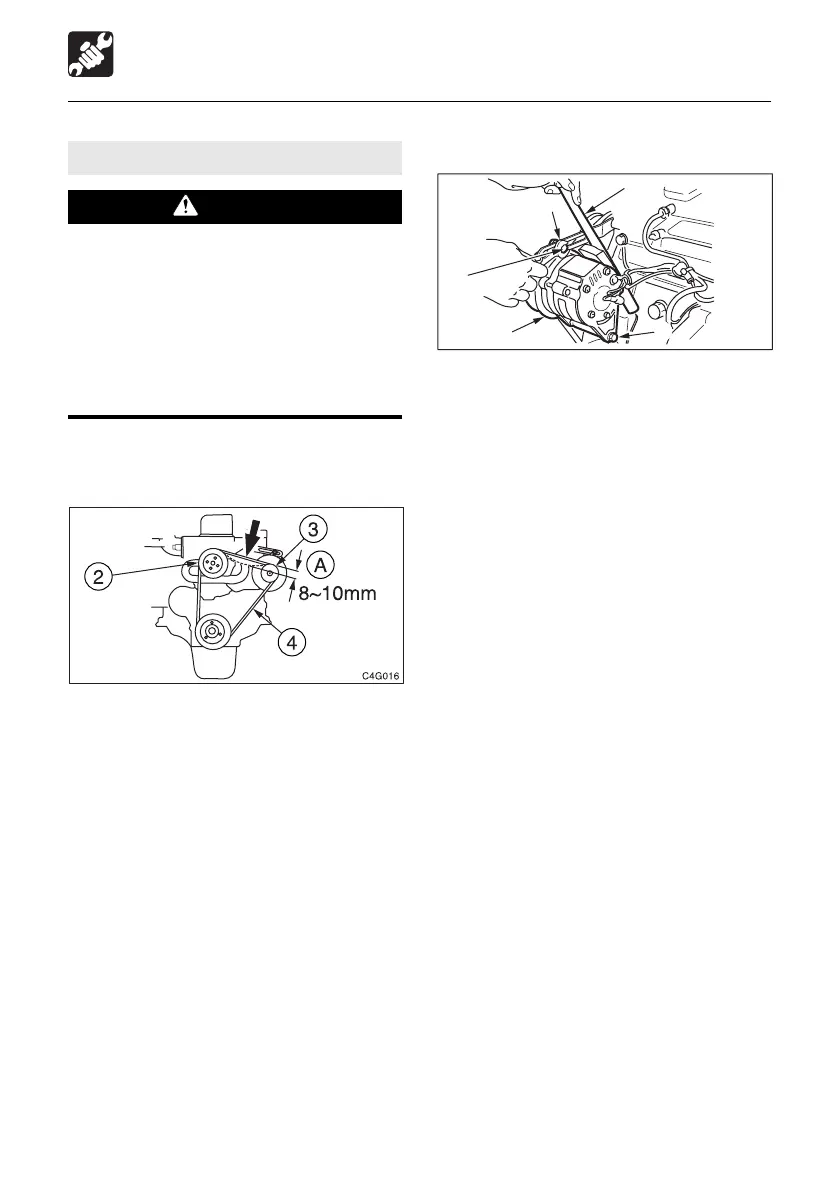

2.Press at the center of the fan pulley (2)

and alternator pulley (3) and check the

tension (about 10 kg or 22 lb.).

The slack (A) should be about 8 to10 mm

(0.3 to 0.4 in.).

3.Inspect the fan belt (4) and replace it if:

¡there are cuts or cracks.

¡the belt is worn and touches the bottom

of the V groove in the pulley.

¡the belt stretches and cannot be

adjusted.

WARNING

E4G018

7

6

8

5

B

Loading...

Loading...