H PISTON FILLERS/STUFFERS

EN-31

Changing the oil:

1) Remove the plug located at the bottom of the machine’s base and drain the

oil into an appropriate container. We ask that you please recycle the used

oil.

2) Replace the plug, making sure that it is tightly sealed.

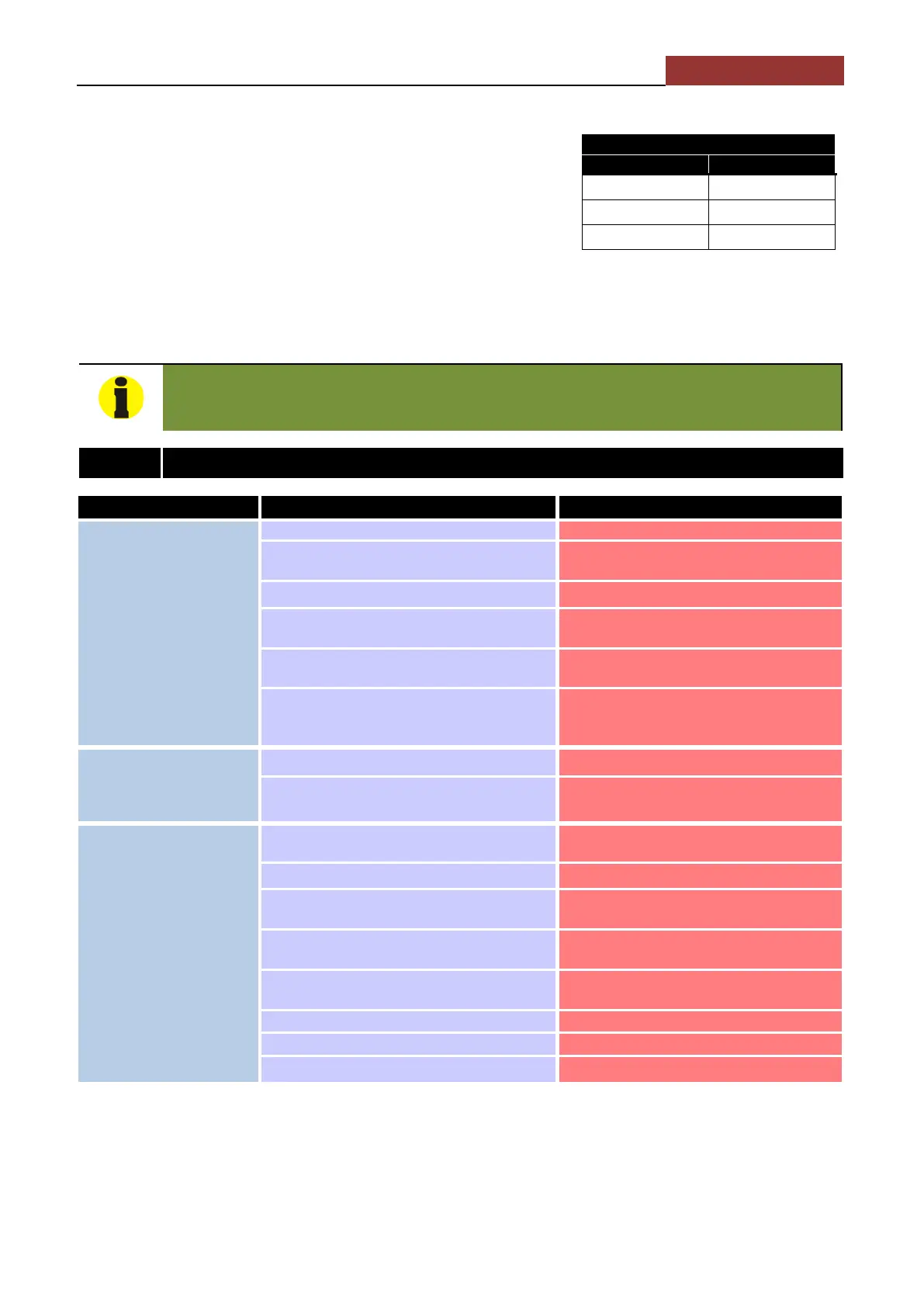

3) Using a funnel, fill the reservoir with the appropriate amount (see table

below) of hydraulic oil via the fill hole at the top of the machine’s base. Do

not fill the reservoir to the top since a certain amount of air must be present

to allow for expansion. Fill only to the maximum mark on the dipstick.

4) After filling the reservoir, raise and lower the piston several times to

eliminate air pockets from the hydraulic circuit.

Use oils for medium pressure hydraulic

systems (approximately 100 bar), and of a

viscosity of approximately 5º Engler

(equivalent to IS03498: cat HL VG46 or

DIN8659: HL-46).

Thoroughly wipe the lid bolt and bearing with a wet sponge after using the machine so that solidified food

residue (from salts, spices, etc.) won’t impede proper closure of the lid.

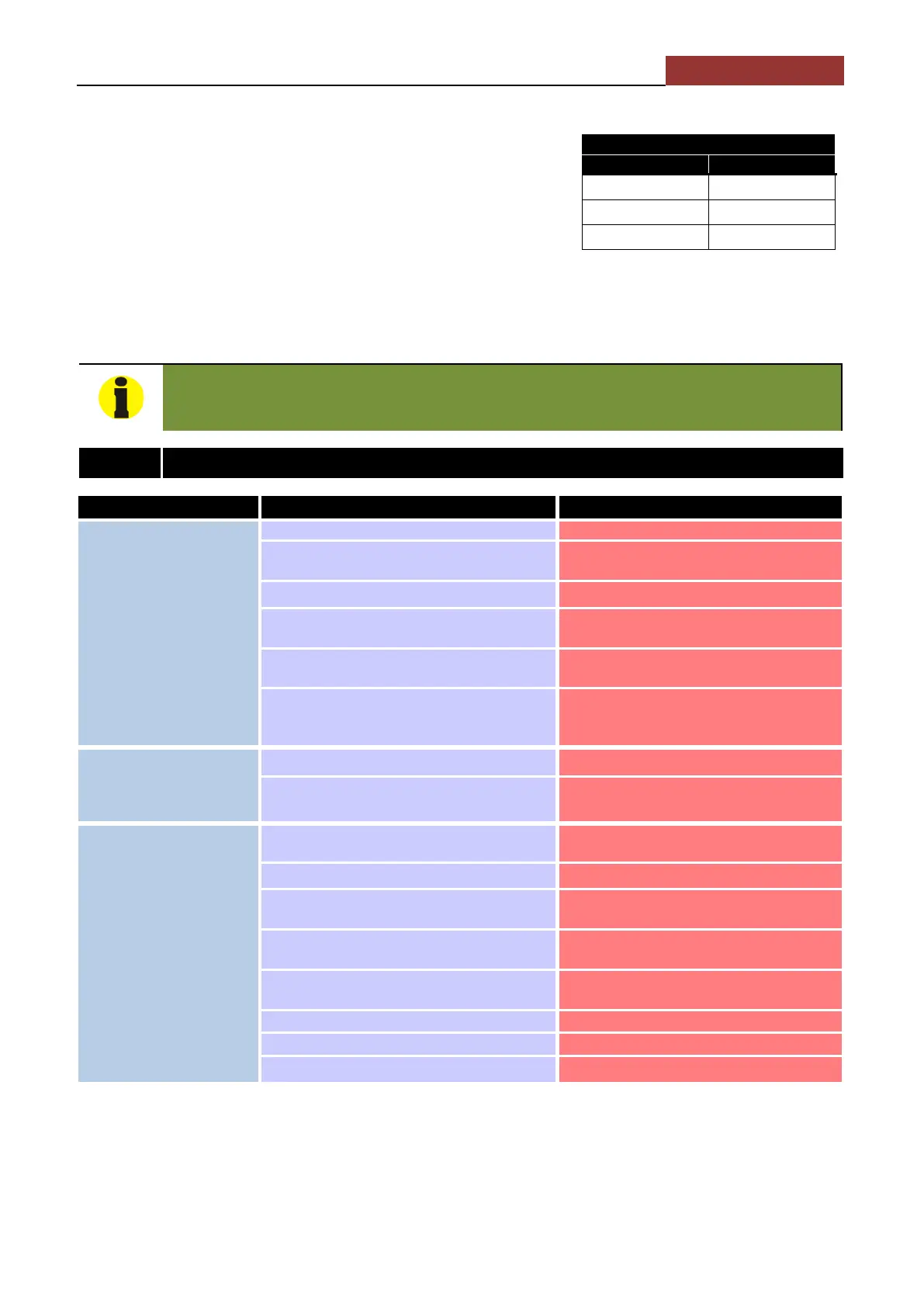

Machine is not plugged to an electrical outlet.

Machine is connected to a voltage lower than that

required by the motor.

Have a qualified technician change the voltage.

No voltage in one or more phases.

Check fuses, plugs, and switches.

The manual power is in 0-STOP position (“I”

models only).

Turn the switch to the 1-START position.

The manual power switch (I models only) is

defective.

Have a qualified technician replace the switch.

The internal on/off microswitch in the knee lever

is defective or not properly adjusted (A models

only).

Have a qualified technician replace or adjust

the microswitch.

Electric motor runs, but the

piston does not move up or

down when using the knee

lever.

Pressure regulator is set to minimum.

Turn the pressure regulator knob clockwise.

Motor is turning in the wrong direction.

Have a qualified technician interchange two of

the three phases in the plug.

Piston moves up and down

but machine seems to lack

power.

The air holes located at the base of the barrel

may be obstructed.

Make sure the air holes are unobstructed.

Piston and piston gaskets are dirty.

Clean the piston and piston gaskets.

Voltage of the power source is not compatible

with voltage selected for the motor.

Have a qualified technician change the motor

voltage.

Three-phase motor (if available) is only

functioning with two phases.

Adjust phases at the power source.

The hydraulic oil level is low.

Fill the oil reservoir to the “MAX.” mark on the

oil cap/dipstick.

A leak between the hydraulic chambers.

Call your local dealer for service.

There is a leak in the hydraulic circuit.

Call your local dealer for service.

Call your local dealer to have it replaced.

Contact your local authorized TALSA dealer with any questions or concerns you have that are not addressed in this manual;

they will be delighted to provide you with additional information and assistance.

www.talsaparts.com

www.davisonsbutcher.com

Loading...

Loading...