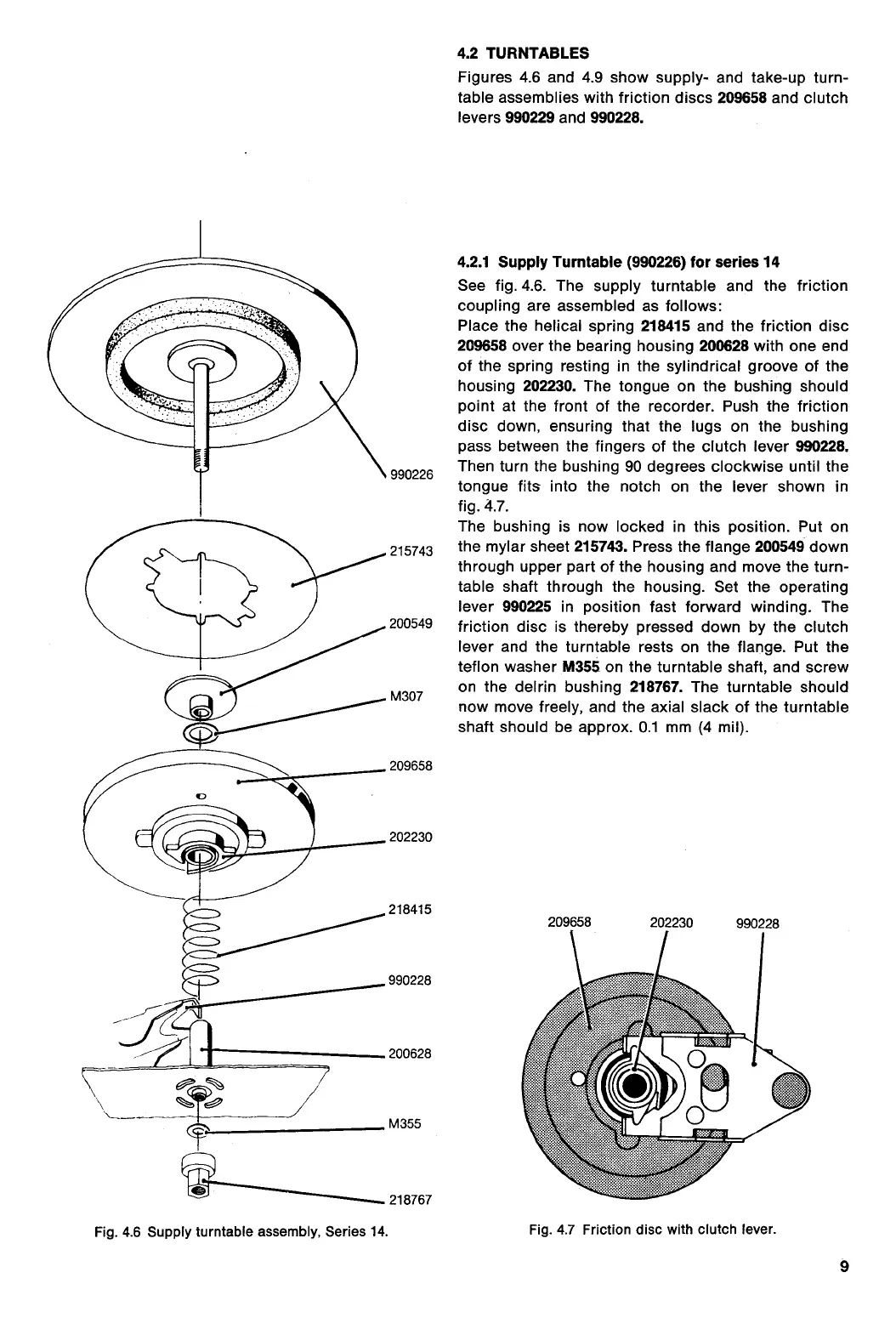

4.2.1 Supply Turntable (990226) for series 14

See fig. 4.6. The supply turntable and the friction

coupling are assembled as follows:

Place the helical spring

218415

and the friction disc

209658

over the bearing housing

200628

with one end

of the spring resting in the sylindrical groove of the

housing

202230.

The tongue on the bushing should

point at the front of the recorder. Push the friction

disc down, ensuring that the lugs on the bushing

pass between the fingers of the clutch lever

990228.

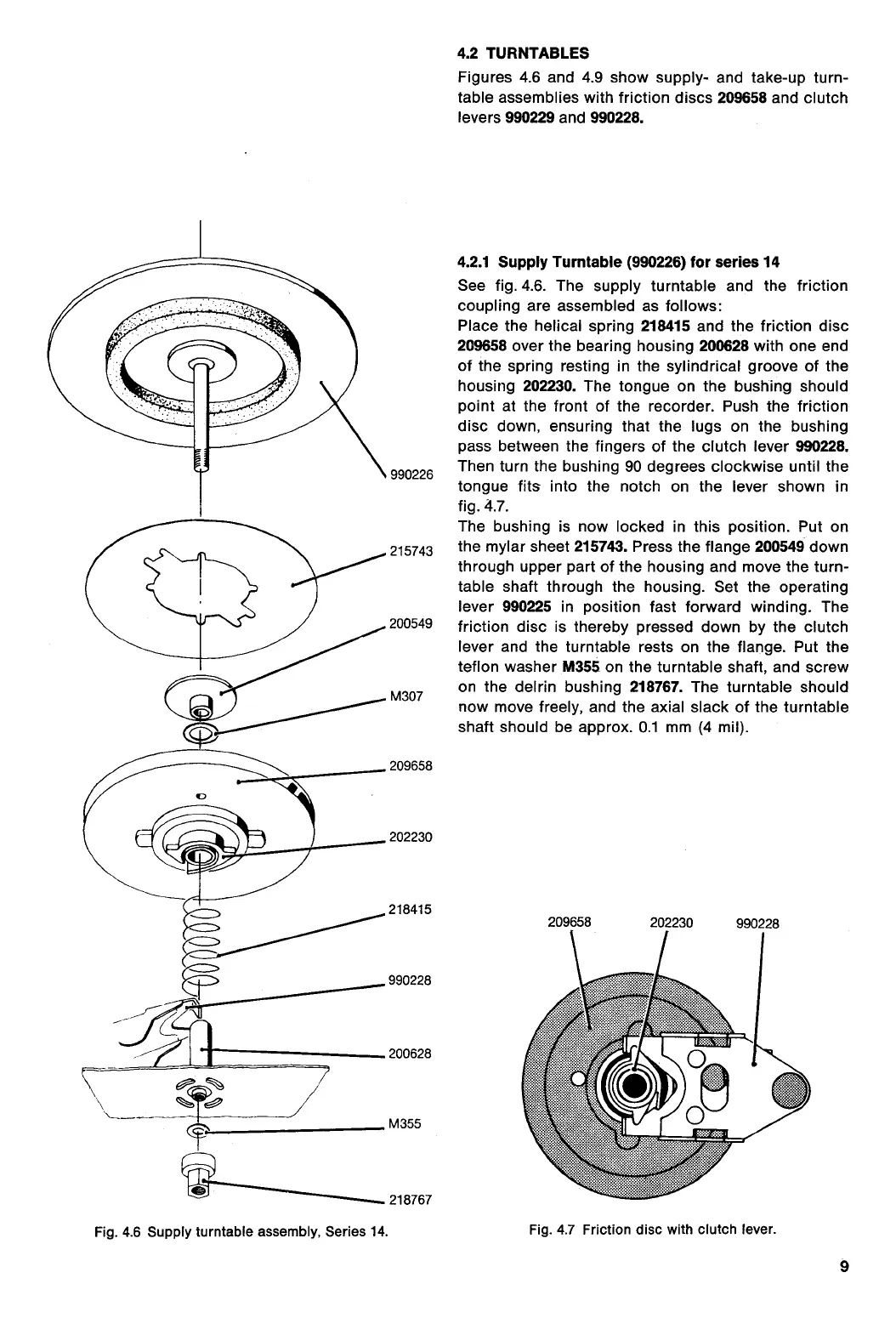

990226 Then turn the bushing 90 degrees clockwise until the

tongue fits into the notch on the lever shown in

fig. 4.7.

The bushing is now locked in this position. Put on

215743 the mylar sheet

215743.

Press the flange

200549

down

through upper part of the housing and move the turn-

table shaft through the housing. Set the operating

lever

990225

in position fast forward winding. The

200549

friction disc is thereby pressed down by the clutch

(::**--****-----------....------

lever and the turntable rests on the flange. Put the

teflon washer

M355

on the turntable shaft, and screw

m307

on the delrin bushing

218767.

The turntable should

now move freely, and the axial slack of the turntable

shaft should be approx. 0.1 mm (4 mil).

209658

202230

218415

990228

200628

M355

218767

Fig. 4.6 Supply turntable assembly, Series 14.

209658

202230

990228

Fig. 4.7 Friction disc with clutch lever.

4.2 TURNTABLES

Figures 4.6 and 4.9 show supply- and take-up turn-

table assemblies with friction discs

209658

and clutch

levers

990229

and

990228.

9

Loading...

Loading...