210520

216540

990234

215563 201605

990202 KOMPL.

218063

212273

215405

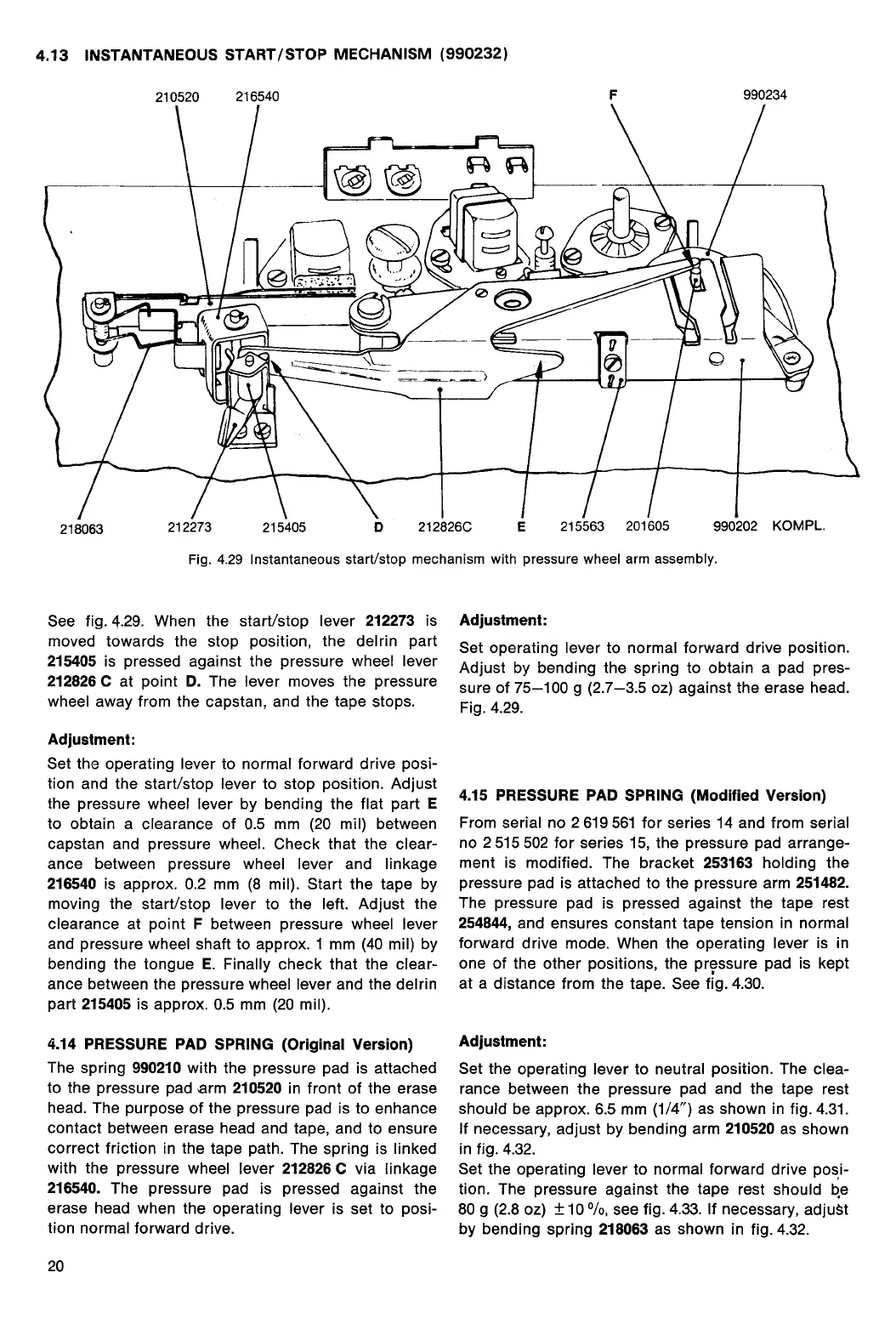

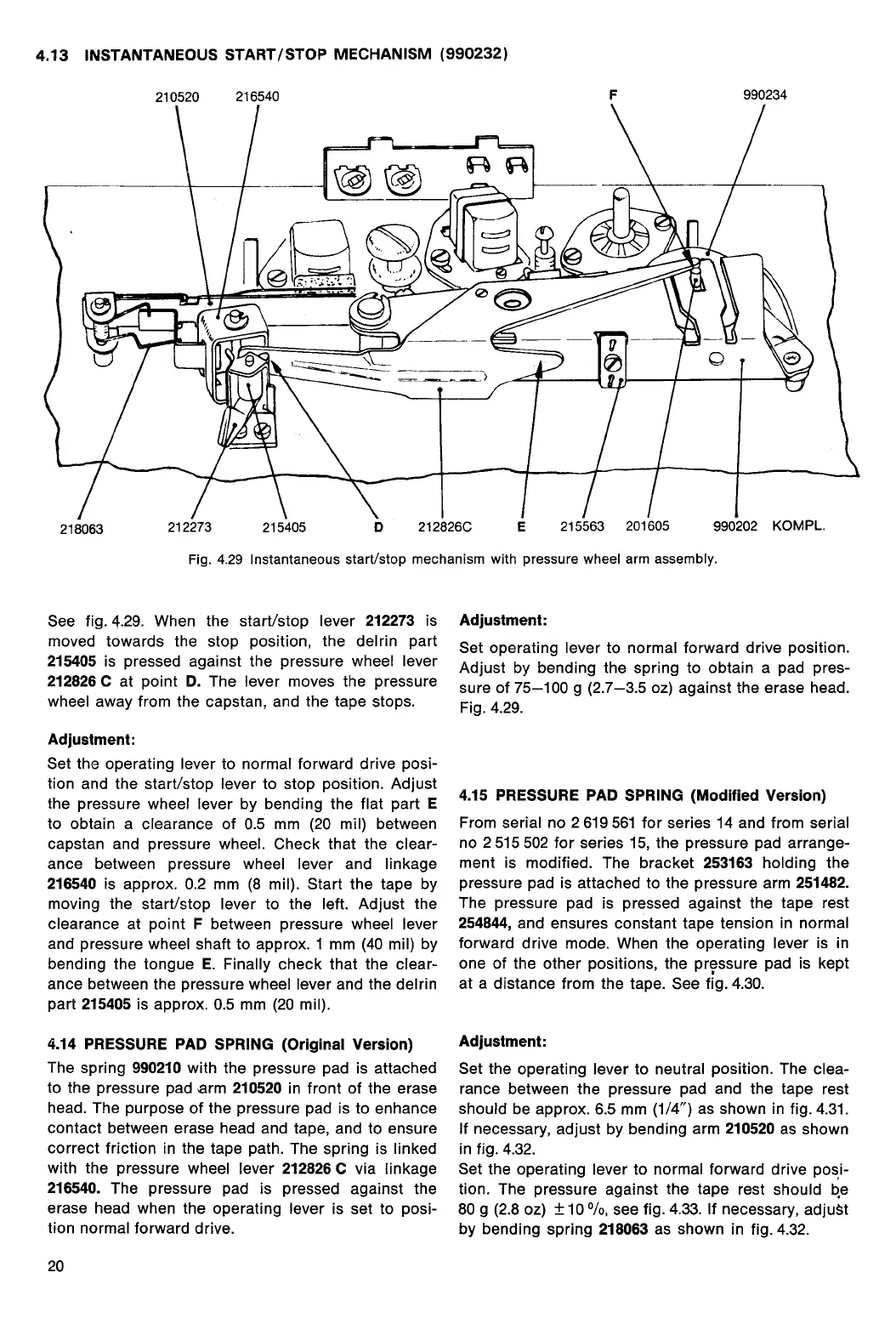

4.13 INSTANTANEOUS START/STOP MECHANISM (990232)

Fig. 4.29 Instantaneous start/stop mechanism with pressure wheel arm assembly.

See fig. 4.29. When the start/stop lever

212273

is

moved towards the stop position, the delrin part

215405

is pressed against the pressure wheel lever

212826 C

at point

D.

The lever moves the pressure

wheel away from the capstan, and the tape stops.

Adjustment:

Set the operating lever to normal forward drive posi-

tion and the start/stop lever to stop position. Adjust

the pressure wheel lever by bending the flat part

E

to obtain a clearance of 0.5 mm (20 mil) between

capstan and pressure wheel. Check that the clear-

ance between pressure wheel lever and linkage

216540

is approx. 0.2 mm (8 mil). Start the tape by

moving the start/stop lever to the left. Adjust the

clearance at point

F

between pressure wheel lever

and pressure wheel shaft to approx. 1 mm (40 mil) by

bending the tongue

E.

Finally check that the clear-

ance between the pressure wheel lever and the delrin

part

215405

is approx. 0.5 mm (20 mil).

4.14 PRESSURE PAD SPRING (Original Version)

The spring

990210

with the pressure pad is attached

to the pressure pad arm

210520

in front of the erase

head. The purpose of the pressure pad is to enhance

contact between erase head and tape, and to ensure

correct friction in the tape path. The spring is linked

with the pressure wheel lever

212826 C

via linkage

216540.

The pressure pad is pressed against the

erase head when the operating lever is set to posi-

tion normal forward drive.

20

Adjustment:

Set operating lever to normal forward drive position.

Adjust by bending the spring to obtain a pad pres-

sure of 75-100 g (2.7-3.5 oz) against the erase head.

Fig. 4.29.

4.15 PRESSURE PAD SPRING (Modified Version)

From serial no 2 619 561 for series 14 and from serial

no 2 515 502 for series 15, the pressure pad arrange-

ment is modified. The bracket

253163

holding the

pressure pad is attached to the pressure arm

251482.

The pressure pad is pressed against the tape rest

254844,

and ensures constant tape tension in normal

forward drive mode. When the operating lever is in

one of the other positions, the pressure pad is kept

at a distance from the tape. See fig. 4.30.

Adjustment:

Set the operating lever to neutral position. The clea-

rance between the pressure pad and the tape rest

should be approx. 6.5 mm (1/4") as shown in fig. 4.31.

If necessary, adjust by bending arm

210520

as shown

in fig. 4.32.

Set the operating lever to normal forward drive posi-

tion. The pressure against the tape rest should be

80 g (2.8 oz) ± 10

0

/0, see fig. 4.33. If necessary, adjuM

by bending spring

218063

as shown in fig. 4.32.

Loading...

Loading...