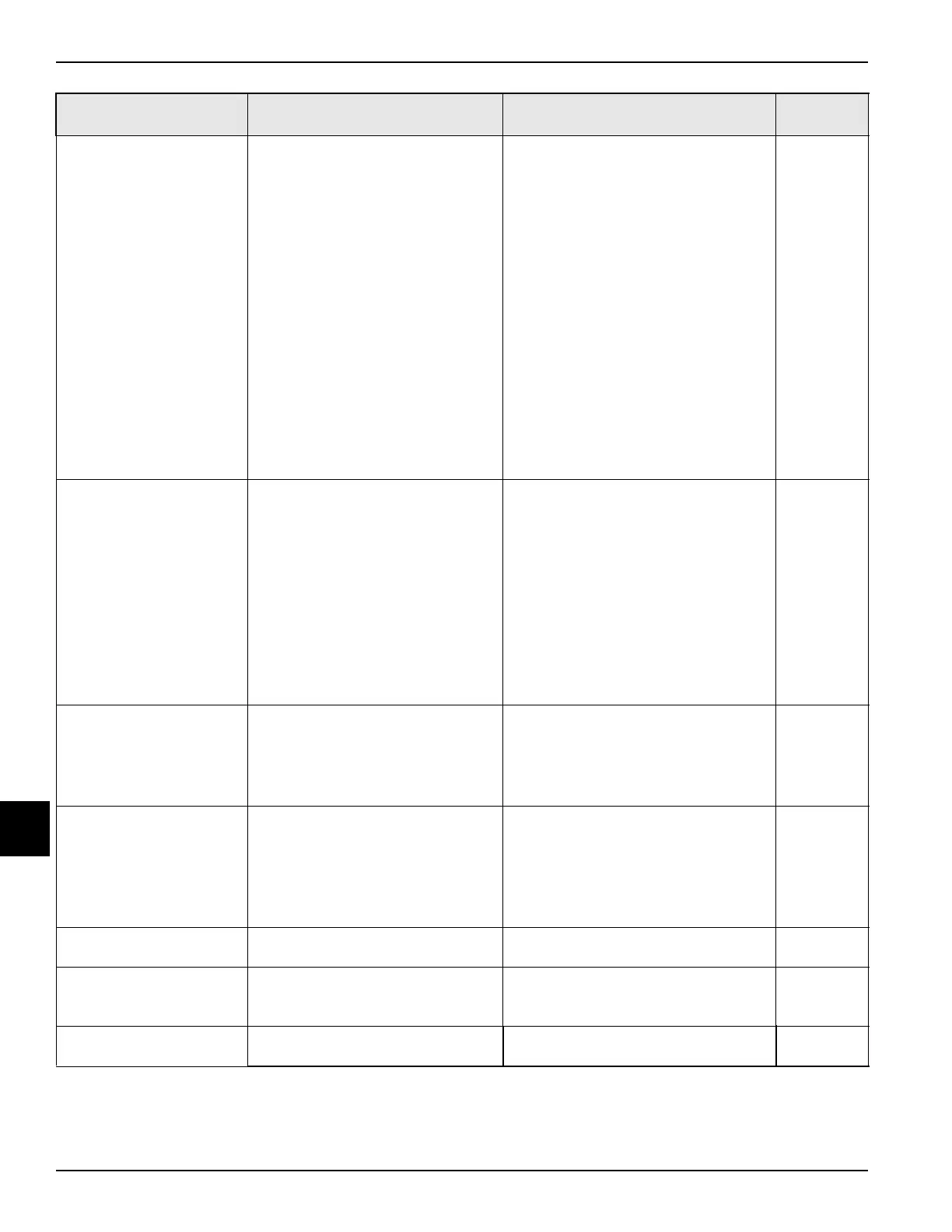

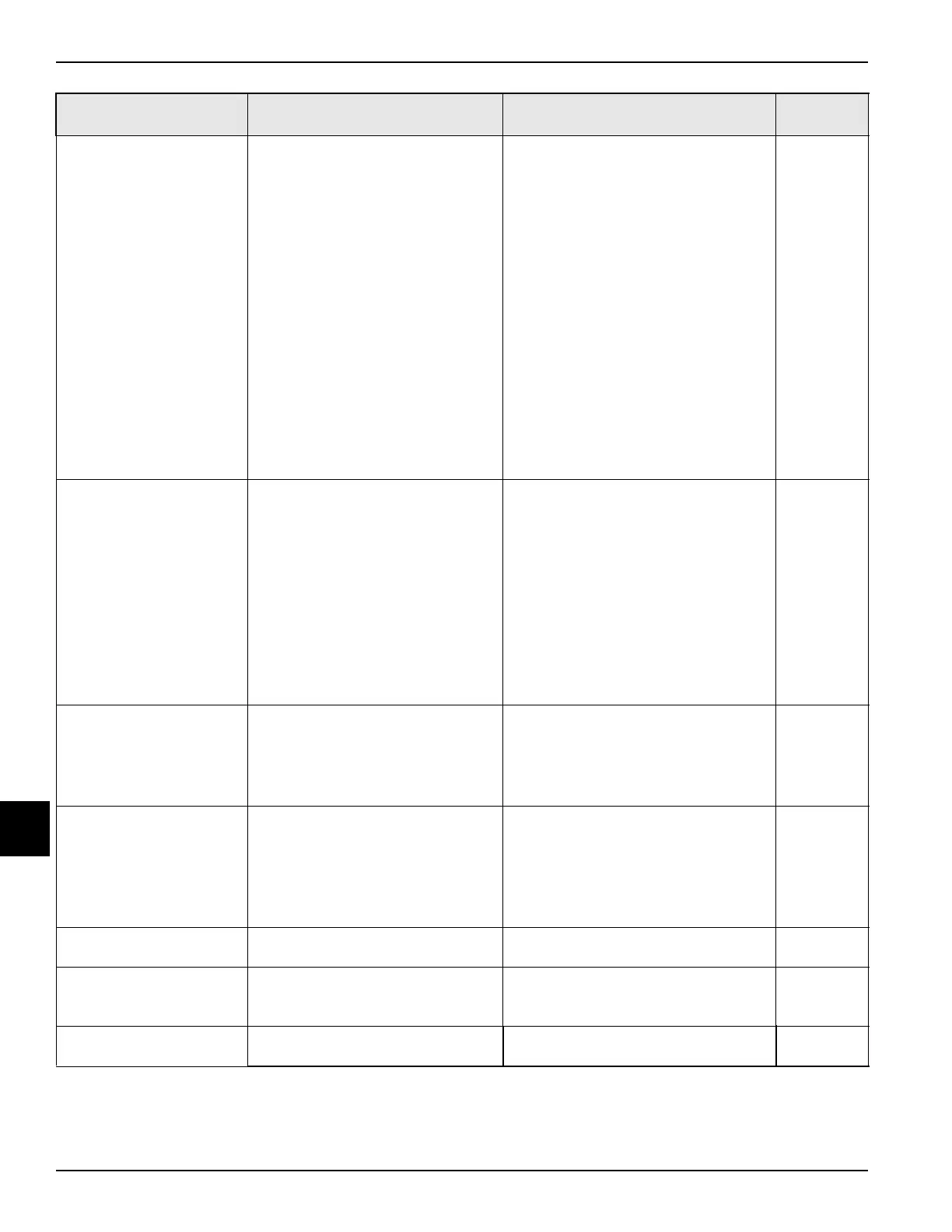

8-2

TROUBLESHOOTING GUIDE

Models C709 & C717

Troubleshooting Guide

8

3. No product is being

dispensed.

a. Low on mix. The MIX OUT light is

on.

a. Add mix to the mix hopper. Return to

Auto mode.

6-7

b. The power switch is in the OFF

position.

b. Move the power switch to the ON

position and select Auto mode.

6-7

c. The circuit breaker is off or the fuse

is blown.

c. Turn the breaker on or replace the

fuse.

- - -

d. Beater motor is out on reset.

BEATER OVERLOAD message

appears.

d. Turn the machine off. Press the

RESET button. Restart the machine

in Auto mode.

- - -

e. Machine is not in Auto mode. e. Select Auto mode and allow machine

to cycle off before drawing product.

6-10

f. Feed tube not properly installed. f. Make sure the feed tube is properly

installed.

6-7

g. Freeze-up in mix inlet hole. g. Call a service technician.

- - -

h. The beater is rotating

counterclockwise when observed

from the operator end.

h. Contact a service technician to

correct rotation.

- - -

4. The product is too soft. a. Draw rate is set too fast. a. Adjust draw rate of 5 oz.to 7 1/2 oz.

(142 g to 213 g) of product by weight

in 10 seconds.

6-2

b. Not enough airspace around

machine (air-cooled machines).

b. Allow for adequate airflow across the

condenser.

1-2

c. Worn scraper blades. c. Replace regularly. 9-1

d. Dirty condenser (A/C). d. Clean monthly. 7-1

e. Mix is out of date. e. Use only fresh mix. - - -

f. Loss of water (W/C). f. Locate cause of water loss and

correct.

7-2

g. Viscosity needs adjustment. g. Contact service technician. - - -

5. The product is too

thick.

a. Freezing cylinder not primed

correctly.

a. Drain the freezing cylinder and

reprime the machine.

6-7

b. The viscosity control is set too

cold.

b. Call a service technician. - - -

c. Freeze-up in mix inlet hole. c. Call a service technician. - - -

6. The mix in the hopper

is too warm.

a. Hopper cover is not in position. a. Clean and sanitize the hopper cover

and place in position.

6-7

b. The agitator is not installed. b. Clean and sanitize the agitator and

install.

6-8

c. The hopper temperature is out of

adjustment.

c. Call a service technician. - - -

7. The mix in the hopper

is too cold.

a. The hopper temperature is out of

adjustment.

a. Call a service technician. - - -

8. Mix Low and Mix Out

probes are not

functioning.

a. Milkstone buildup in the hopper. a. Clean hopper(s) thoroughly. 6-7

9. Product is collecting on

top of the freezer door.

a. The top O-ring on draw valve is

improperly lubricated or worn.

a. Lubricate properly or replace the

O-ring.

6-4

Problem Probable Cause Remedy

Page

Ref.

Loading...

Loading...