114-94438 REV C1

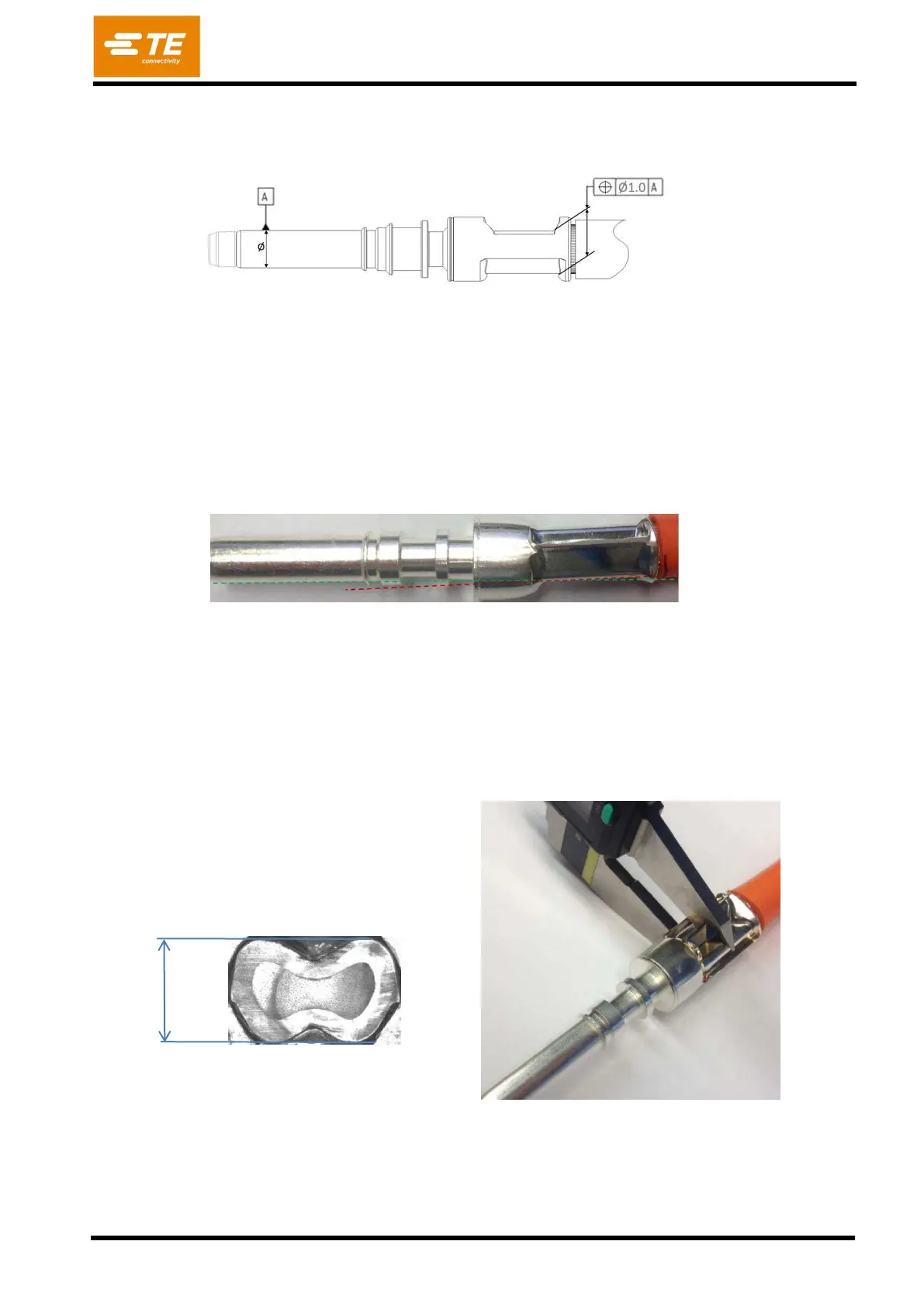

For 50 mm² meeting the specific shape and position tolerances shown at figure 7 must be ensured before

the contact is inserted into the housing.

Measuring the shape and position deviation is not always necessary.

If the contact is obviously straight by eye a simplified shape and position functional test, at diameter 6mm²,

can be performed by inserting it into a suitable housing cavity (crimp may not scrape the walls of secondary

lock).

If contacts are bent during the application process exceeding the specification limits they may not be bent

back and must be rejected.

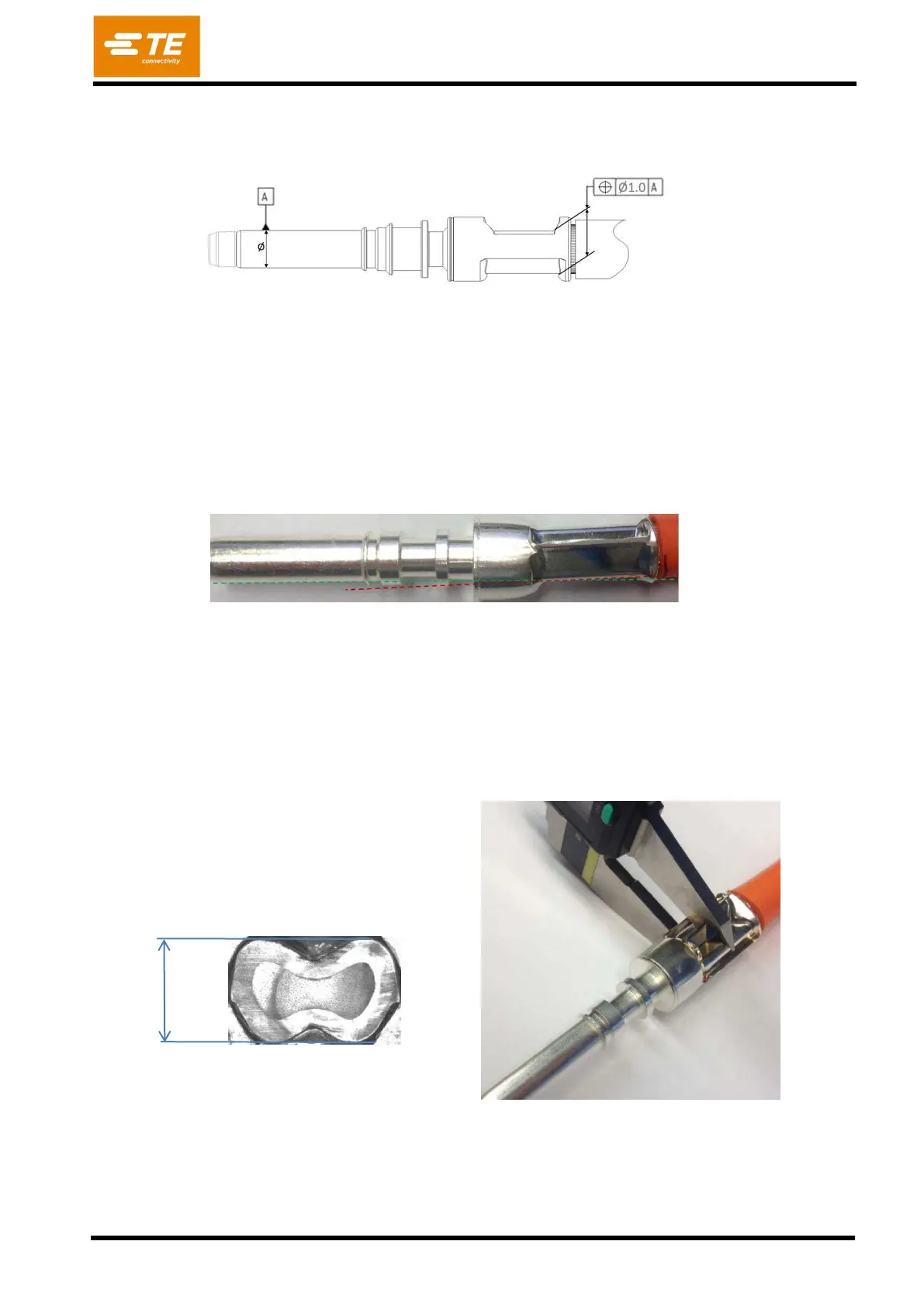

5.9. Measuring equipment and measuring position

As measuring equipment for measuring crimp height, a digital caliper with accuracy of measuring

0.01mm is required. Measuring of crimp height, has to be done always in middle of crimp area,

across whole crimp.

Loading...

Loading...