Page 28 SC2000 Manual – 177/52301 Rev G 22

nd

October

2004

10.1.25 Fail-safe

The controller’s safety system includes a microprocessor watchdog which can detect

software failure, and a hardware fail-safe system which can prevent dangerous runaway

conditions in the event of certain hardware failures.

Every time the controller is powered-up, the software checks that the fail-safe circuit is able to

switch off the Mosfets and open at least 2 contactors.

10.1.26 Dual Motor Operation - General Principles

The SC2000 can drive twin traction motor systems using either a single chopper (non-

proportional control) or a twin chopper (proportional control). In both modes, 2 of the

contactor drive outputs must be assigned as an additional set of direction contactors for the

second motor. Depending on the steering angle, the inner motor of a turn can be reduced in

speed, and then reversed (for 3-wheel vehicles). For increased safety, the overall speed of

the vehicle can also be reduced as it turns.

The steering information can be provided by either 3 switch inputs (inner-left steer switch,

inner-right steer switch and the outer switches connected in parallel) or a steer potentiometer.

Sevcon recommends a steer pot., as this allows linear inner-wheel control on proportional

systems, and linear speed cutback in turns on all vehicles. As the steering characteristics for

a potentiometer can be adjusted via the calibrator (items 1.1.29 and 1.1.31), mechanical

adjustment is not required. See section 7.3.1 for typical values. The inner angle and outer

angles personalities must be at least 5° apart. If problems exist with setting the values, check

the other setting to ensure it is not within 5 degrees.

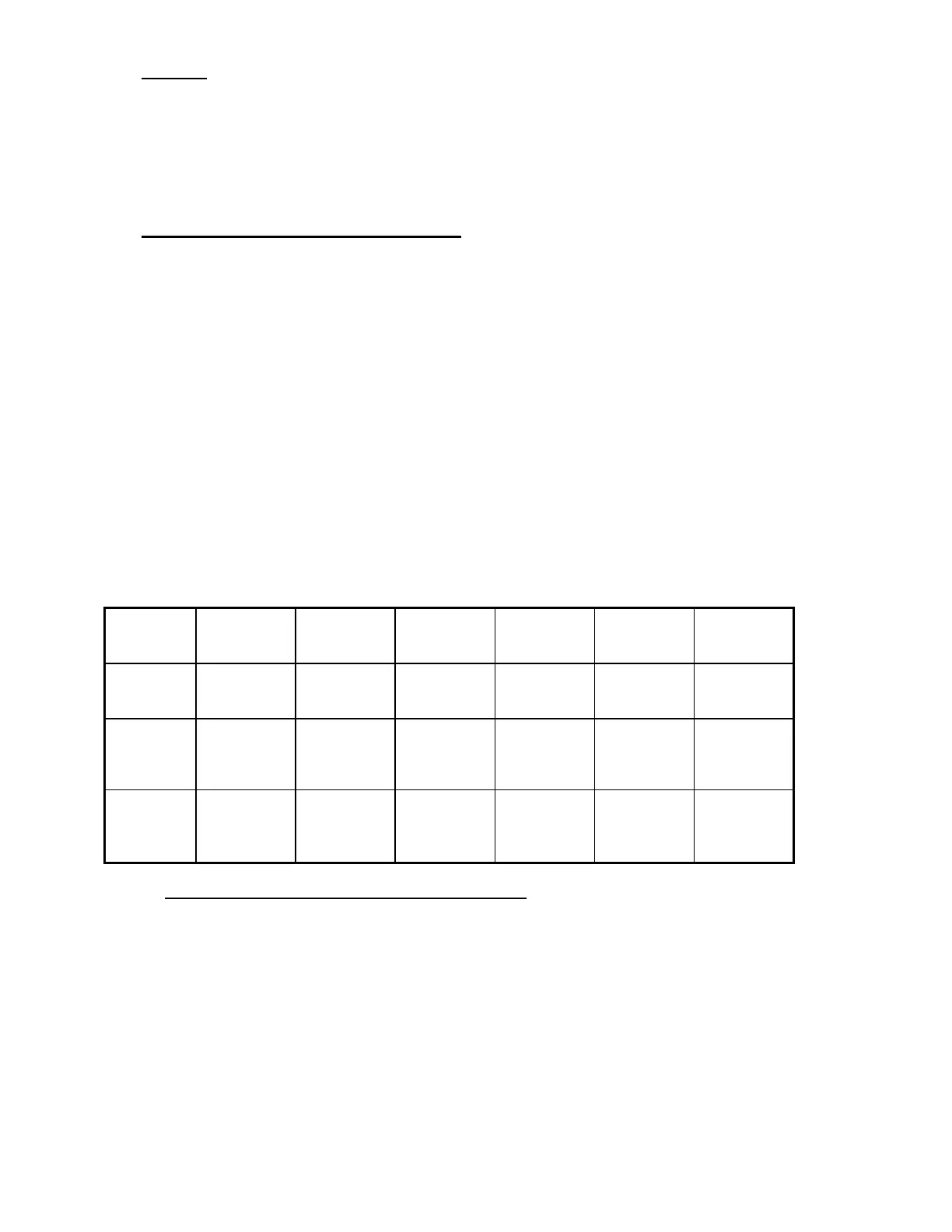

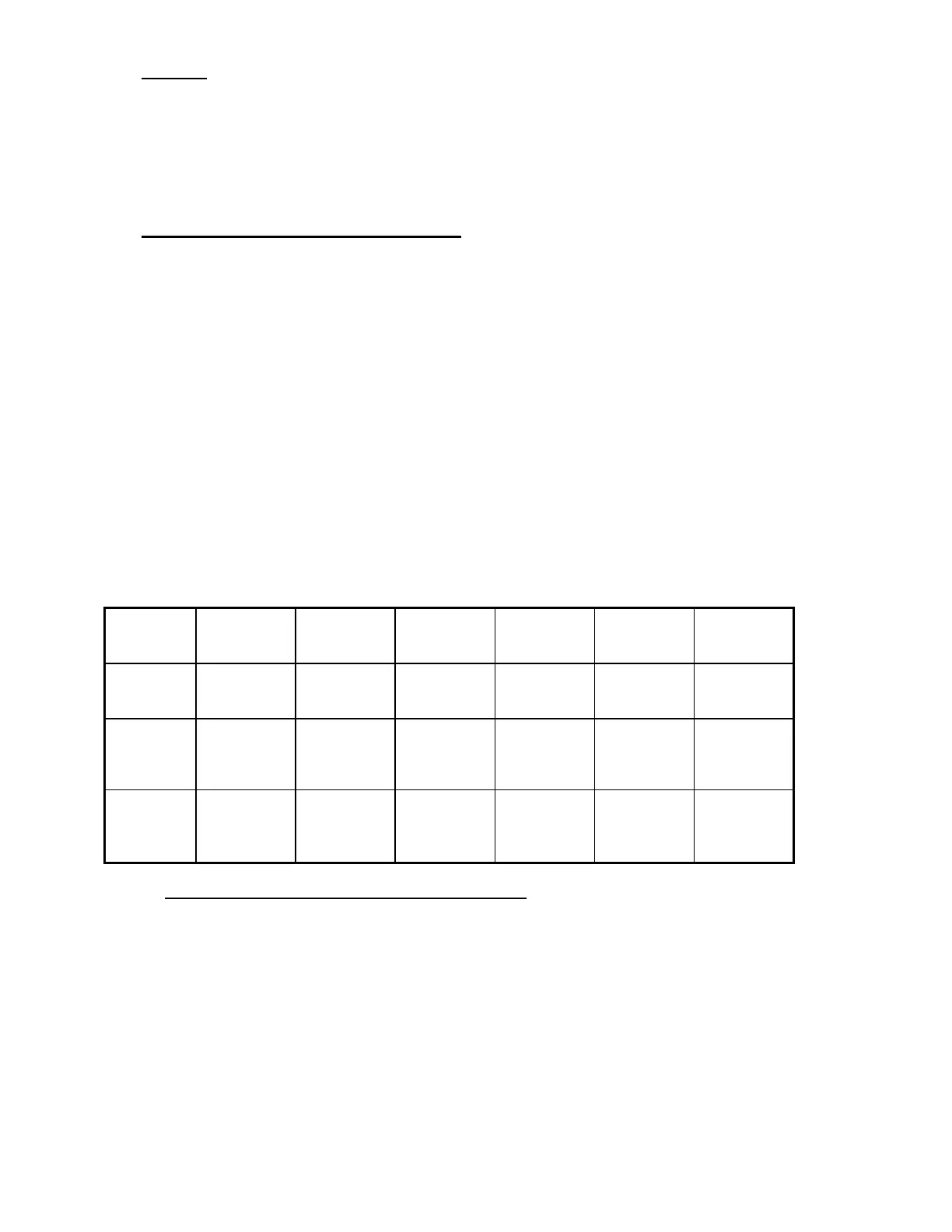

For all dual motor systems, the steering range 0 - 90° is split into 3 sections: the dead-band,

the cut-band and the reverse-band. The characteristics of each are shown below:

Band Definition

for Steer

Pot.

Definition

for Steer

Switches

Maximum

Vehicle

Speed

Inner Motor

Speed

Inner Motor

Direction

Bypass &

Field

Weakening

Dead Band

e.g.

0° - 10°

steer angle

is less than

inner angle

all steer

switches

open

100% 100% Same as

direction

lever

Enabled

Cut Band

e.g.

10° - 70°

steer angle

is between

inner and

outer angles

one inner

switch is

closed

reduced to

cutback

speed #1

reduced to

0%

Same as

direction

lever (or

stationary)

Disabled

Reverse

Band

e.g.

70° - 90°

steer angle

is greater

than outer

angle

one inner

and outer

switch is

closed

reduced to

cutback

speed #2

increased to

cutback

speed #2

Opposite of

direction

lever

Disabled

10.1.27 Dual Motor Non-proportional - Additional Notes

Depending on how closely the motor characteristics are matched and whether circulating

currents exist between the two motors during braking, a balancing contactor may be required

(see Figs 5 & 7). The balance contactor is open when driving, and closed under all other

normal conditions.

To minimise lurches during cornering the chopper is ramped-down using the standard

acceleration delay prior to changing the direction of the inner wheel. Once the contactors

have changed, the chopper is ramped up at one of two rates depending on the type of

direction change: The inner ramp rate is used between the dead-band and the cut band, and

the outer ramp rate is used between the cut band and the reverse band.

Loading...

Loading...