22

nd

October 2004 SC2000 Manual – 177/52301 Rev G Page 31

10.3 GENERAL OPERATION

10.3.1 Operating Frequency

The drive frequency of both the Traction and Pump power frames is 15.67Khz, for silent

operation. For Traction plug and regen-braking the frequency is also 15.67Khz and silent.

10.3.2 Temperature Monitoring

If the temperature of either power frame exceeds 75

o

C its maximum available current will be

reduced. Note, however, that if the set current limit is less than the maximum available

current limit actual cutback will occur at progressively higher temperatures than 75oC. The

thermal cutback ensures that the maximum heatsink temperature is limited to 95

o

C (See

Graph 1). When actual cutback occurs the diagnostic LED will flash 8 times. Inspection of the

calibrator fault messages will indicate which unit is in thermal cutback.

10.3.3 Safe Operating Area (SOA)

The controller’s current may be limited at high and/or low duty cycles depending on its current

and voltage specification. This is to reduce the thermal stress on the power components in

order to increase long term reliability. See Graph 2.

The “Safe Operating Area” is a characteristic of the MOSFETs and Freewheel Diodes which

make up the powerframe. The MOSFET SOA restricts current at high duty cycles on all

configurations, and the Diode SOA tends to restrict the current at lower duty cycles on lower

voltage applications.

For most applications SOA will have little or no effect on the operation of the controller. It’s

effect is more significant in protecting the controller against adverse loads such as damaged

motors and static test rigs.

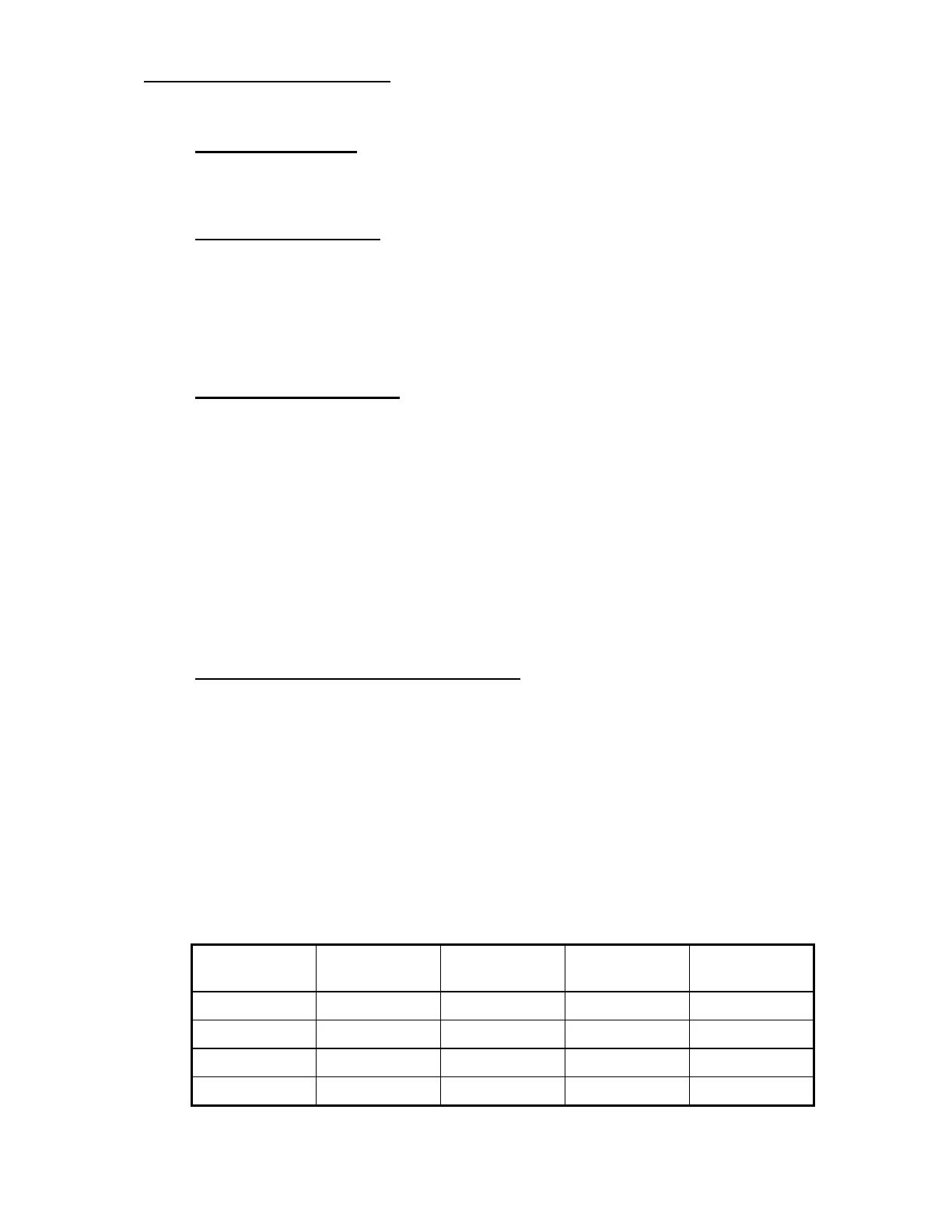

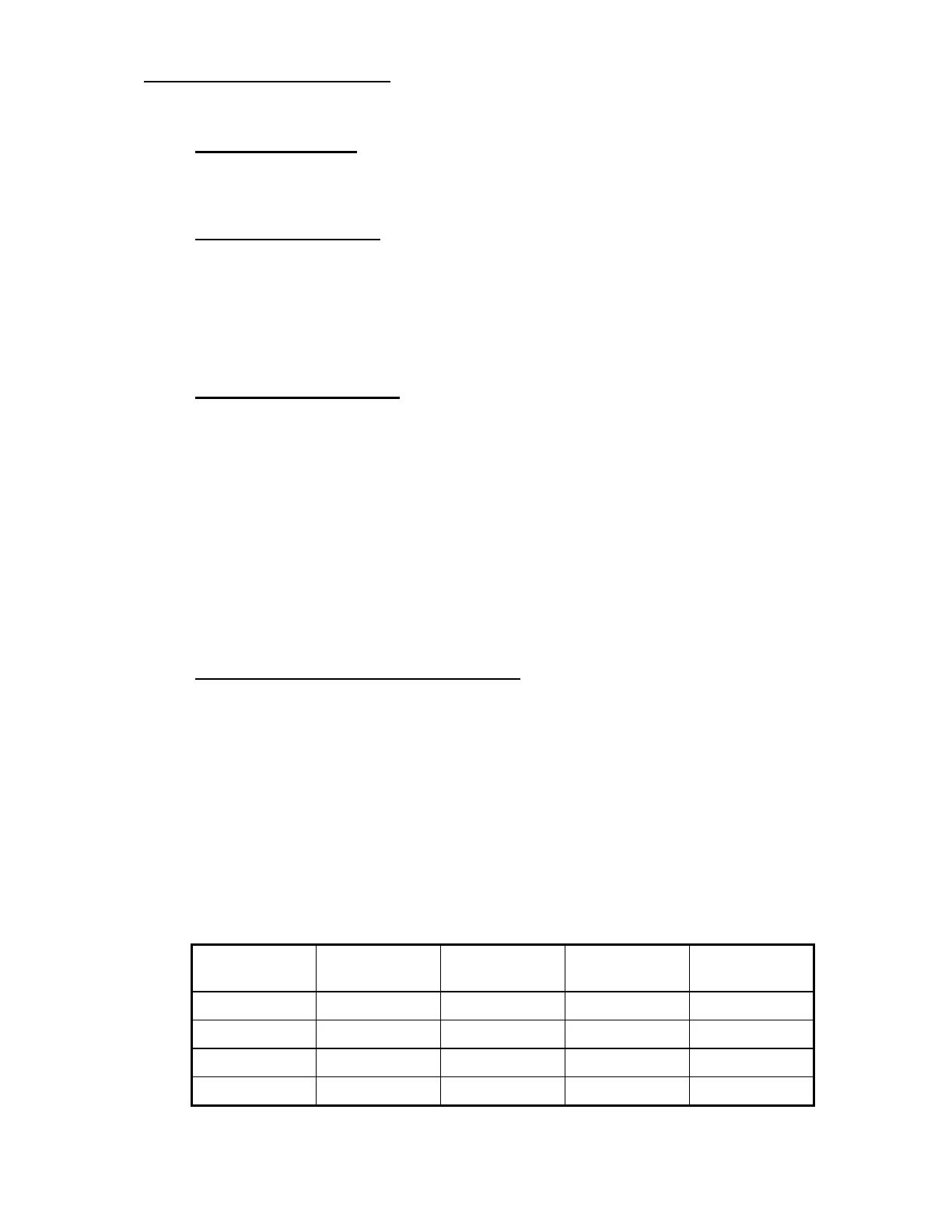

10.3.4 Under-voltage and over-voltage protection

In order to prevent a sudden loss in power, the controller will begin to linearly ramp down the

current limit, once the average battery voltage falls below a pre-set under-voltage start level.

The current will be ramped down to 0 and a 7 flash fault indicated if the averaged battery

voltage falls below the under-voltage cut-out level.

To protect the controller from over-voltage caused by prolonged regen braking the regen

current is cutback linearly from 100% when the average battery voltage reaches the over-

voltage start level, to the minimum braking level at the over-voltage cut-out level.

If the battery voltage exceeds the over-voltage cutout level, all pulsing is stopped and a 7-

flash fault is indicated. This protects against incorrect battery connection.

Nominal

Battery Voltage

Under-voltage

Cutout

Under-Voltage

Start

Over-voltage

Start

Over-voltage

Cutout

24 V 14.5 V 18.0 V 40.0 V 45.0 V

48 V 14.5 V 18.0 V 65.0 V 70.0 V

80 V 43.0 V 60.0 V 95.0 V 100.0 V

96 V 43.0 V 60.0 V 120.0 V 125.0 V

Loading...

Loading...