P-I-D values

The proportional component P amplifies the deviation between the set value and the actual

value. The correcting variable is increased by one level (one increment) per X * 0.1 K deviation

from the set value. A large number makes the system more stable and leads to greater control

deviation.

If the set value and the actual value match, the average of the minimum and maximum correcting

variables will be issued as the correcting variable.

Example: Minimum correcting variable 30, maximum correcting variable 100, set value = actual

value -> correcting variable = 65

The integral component I periodically adjusts the correcting variable in relation to the deviation

remaining from the proportional component. For every 1 K of deviation from the set value, the

correcting variable increases by one level every X seconds. A larger number results in a more

stable system, but the correction towards the set value is slower.

The differential component D causes a short-term overreaction the faster a deviation between the

set value and the actual value occurs, in order to correct it as fast as possible. If the actual value

deviates from the set value at a rate of X * 0.1 K per second, the correcting variable will be

changed by one level. Higher values result in a more stable system but correction towards the set

value is slower.

With the help of the cycle time parameter, the readjustment can be influenced via the differential

component. A longer cycle time results in an extended period of influence for the differential

component.

Pump stoppages

If the correcting variable is too small, it could, for example, result in check valves bringing the pump

to a stop. At times that may be desirable, which is why stage 0 is permitted as the lower limit.

To determine the minimum correcting variable, slowly increase the speed stage in manual mode

while observing the pump. The correcting variable at which the pump starts should be increased by

a few levels to be on the safe side, and the result should be applied as the minimum correcting

variable.

For the control of variable-speed high efficiency [HE] pumps, follow the pump

manufacturer's instructions for the minimum correcting variable and control characteristics

(standard/inverse).

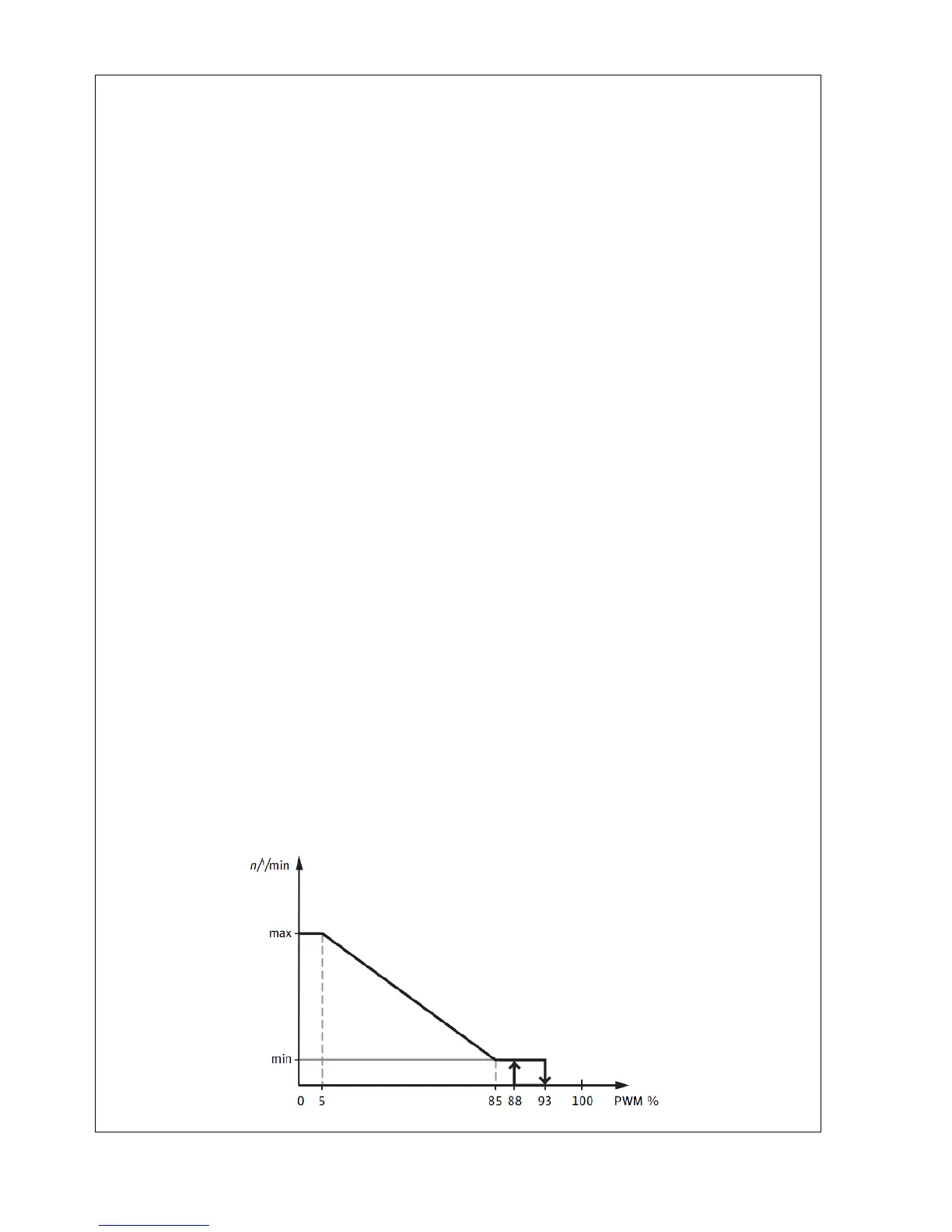

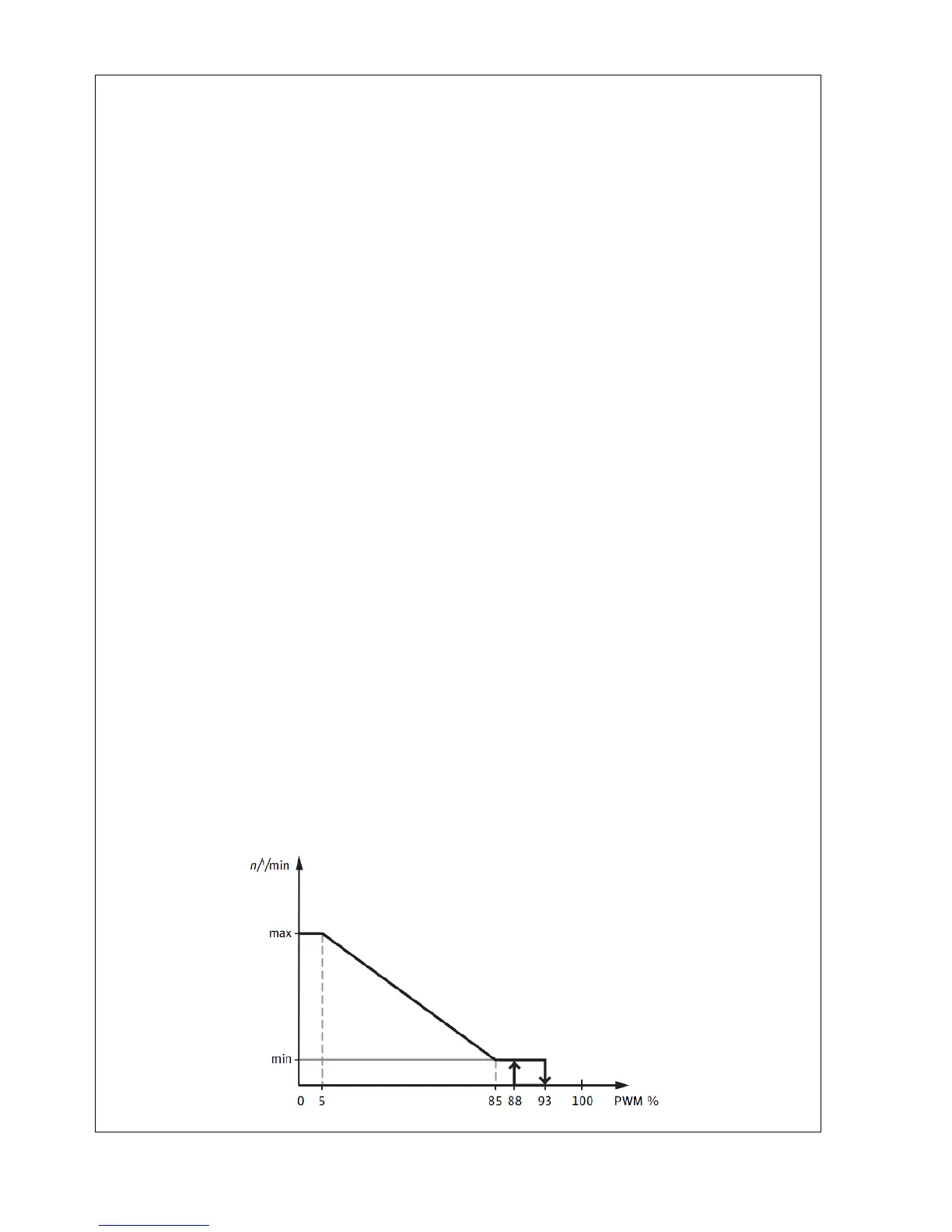

Example: Characteristic of an HE pump with inverse PWM control (Heating mode) (source:

WILO)

Loading...

Loading...