A system with specified sensors is controlled by means of the correcting variable in order to keep a

sensor value constant or to maintain a constant differential between two sensor values.

Example of use: Changing the pump rate, which is to say the throughput, of circulation pumps.

That allows the system to maintain constant temperatures (or temperature differentials).

PID control is not only suitable for speed control, however, but can also be used for burner or heat

pump modulation, for example.

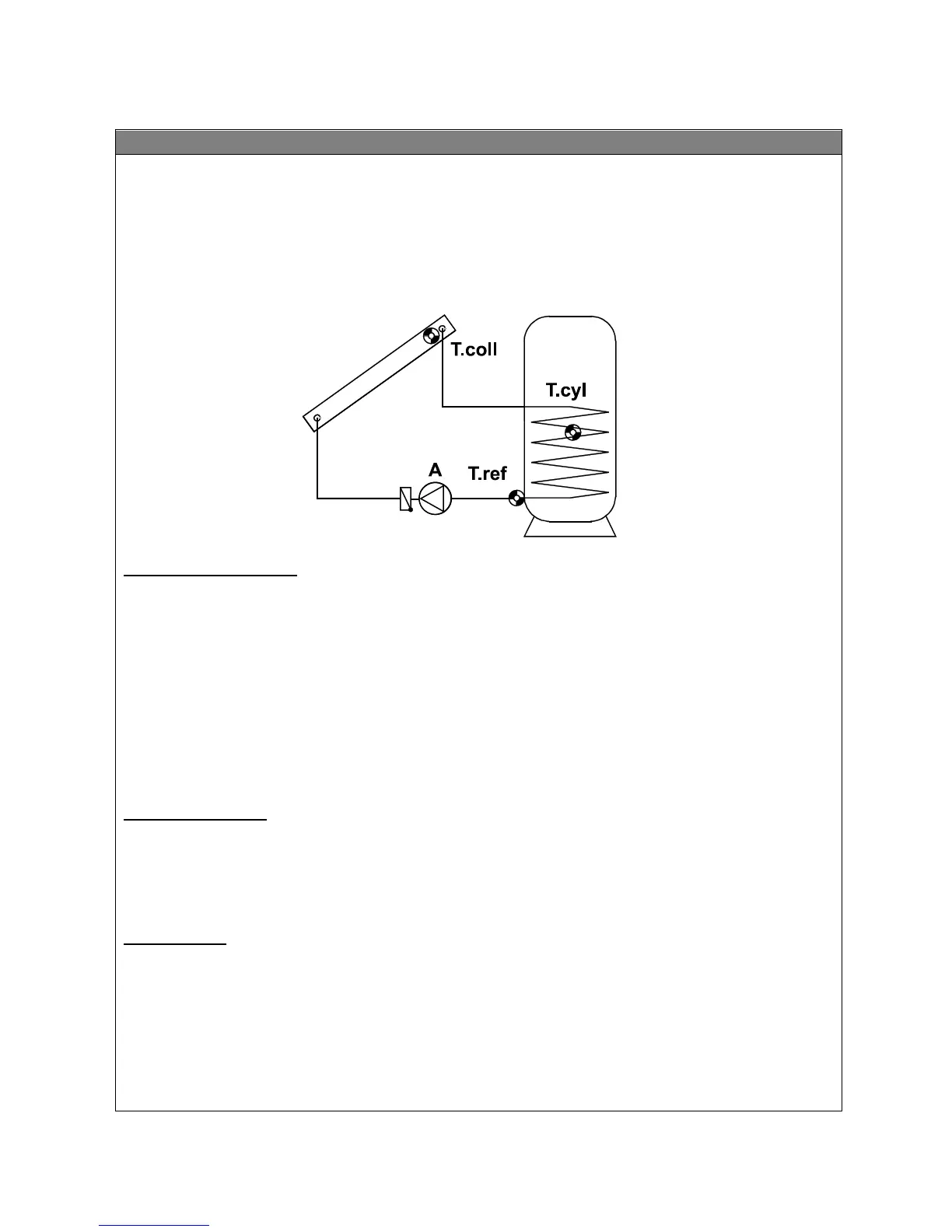

Description using a simple solar layout:

Absolute value control = maintaining a constant value at one sensor

T.coll is kept at a constant temperature (e.g. 60 °C) by means of speed control. If the insolation

levels decrease, T.coll becomes cooler. The controller then reduces the speed and thereby the

flow rate. That causes the heat transfer medium to stay in the collector for a longer heat-up time,

which in turn increases T.coll.

Alternatively, in some systems (e.g. DHW cylinder charging) it may be useful to maintain a constant

return temperature (T.ref). That requires an inverse control characteristic. If T.ref is increasing, the

indirect coil is transferring too little energy to the cylinder. The flow rate is therefore reduced. A

longer dwell time in the indirect coil cools the heat transfer medium more, thus reducing T.ref.

Keeping T.cyl constant would not be useful because changing the flow rate would not directly

affect T.cyl and thus no functioning control loop would be created.

Differential control = maintaining a constant temperature differential between two sensors.

Keeping a constant differential in temperature between T.coll and T.ref results in modulating

operation of the collector. If T.coll drops as a result of reduced insolation, the differential between

T.coll and T.ref will drop as well. The controller then reduces the speed, leading to a longer dwell

time of the medium in the collector, thus increasing the T.coll - T.ref differential.

Event control = If a defined temperature event occurs, event control activates, blocking absolute

value control and/or differential control. The constant value is maintained at the relevant sensor in

the same way as for absolute value control.

Example: The collector is to be kept at a certain temperature once T.cyl has reached 60 °C (the

activation threshold).

Note: If absolute value control (maintaining a constant value at one sensor) and differential control

(maintaining a constant differential between two sensors) are both active simultaneously, the

lower value of the two methods wins out.

Loading...

Loading...