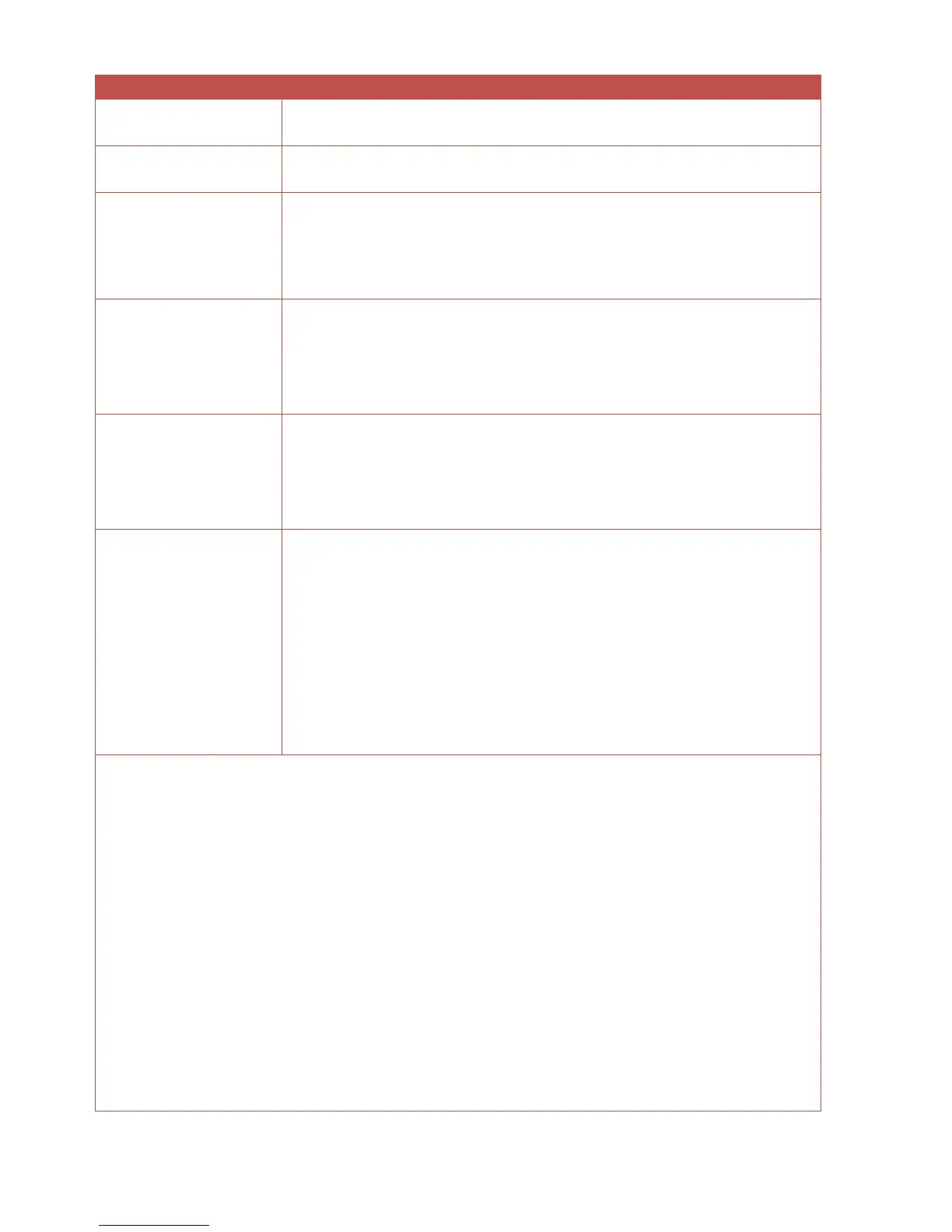

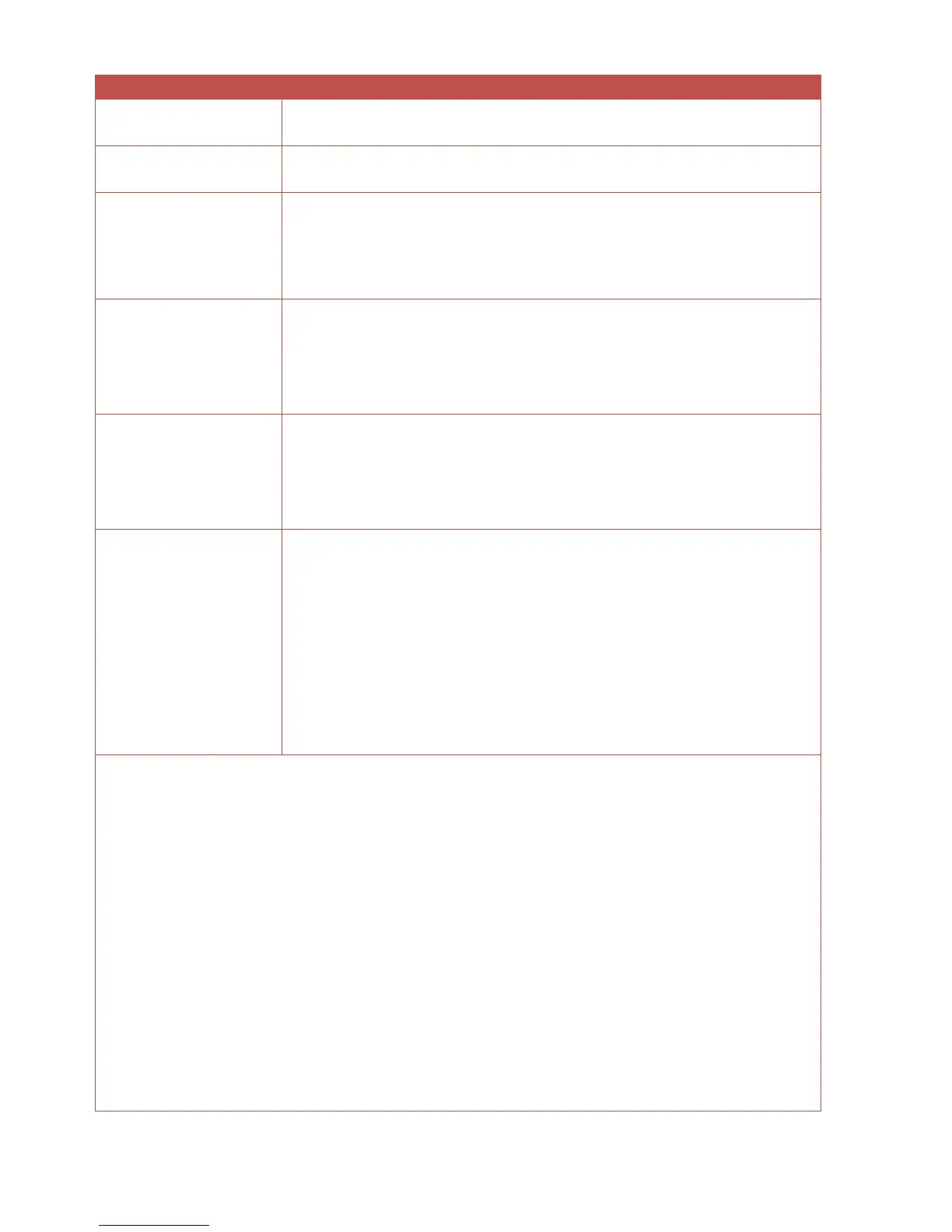

A wide range of function quantities are available, which are applied

together with their unit and their decimal places.

Cycle time = interval between measurements for correction via the

differential value (see Function description / P-I-D values)

Reset

integral counter

(only visible if the

"Corr. var at start" is

unused)

If "No" is selected, PID control starts after enabling with the correcting

variable that was last issued.

If "Yes" is selected, PID control immediately begins after enabling, with

the correcting variable calculated based on the input variables and

parameters

Absolute value ctrl

Mode

Set value abs.

Available for selection: Off

Standard = the correcting variable increases as the actual value

rises

Inverse = the correcting variable falls as the actual value rises

Display of the set value

Differential control

Mode

Set value diff.

Available for selection: Off

Standard = the correcting variable increases as the differential

increases

Inverse = the correcting variable falls as the differential increases

Display of the differential

Event control

Mode

Condition

Activ. threshold

Diff. on

Diff. off

Set value event

Available for selection: Off

Standard = the correcting variable increases as the actual value

rises when event control is active

Inverse = the correcting variable falls as the actual value rises

when event control is active

Available for selection: Act. > threshold, Act. < threshold

Display of the activation threshold

Start differential for the activation threshold

Stop differential for the activation threshold

Display of the set value for control

➢ Each control method can be set to control modes Standard (correcting variable increases

with rising actual value) or Inverse (correcting variable falls with rising actual value) or to

Off (control method inactive).

➢ Event control overwrites results from other control methods. A defined event will therefore

block absolute value control or differential control.

Example: Absolute value control to keep collector temperature constant at 60 °C is blocked

once the cylinder reaches 50 °C at the top = a usable DHW temperature has thus been

reached quickly, and charging of the cylinder can now continue at the full flow rate (and

consequently at a lower temperature). For this to work, the new set temperature entered in

event control must be a value that will automatically result in pumping at full speed (e.g. for

collector sensor = 10 °C).

➢ If the Condition of event control is Act. < threshold, event control will be activated when

the activation value falls below the activation threshold + Diff. off and will be deactivated

again when it exceeds the activation threshold + Diff. on. With this condition, the two Diff.

values are therefore effectively interchanged.

➢ If both absolute value control and differential control are switched off (output: maximum

correcting variable), then, when event control is activated, the control will change over from

the maximum correcting variable to the value for event control.

Loading...

Loading...