tecn@ SALDATRICI ART. 3401 - 3406 - 3407 - 3408 WELDERS ITEM 3401 - 3406 - 3407 - 3408

Documento numero / Document number: MAN1063 Edizione / Edition: Settembre / September 1997 PAG. 22 / 32

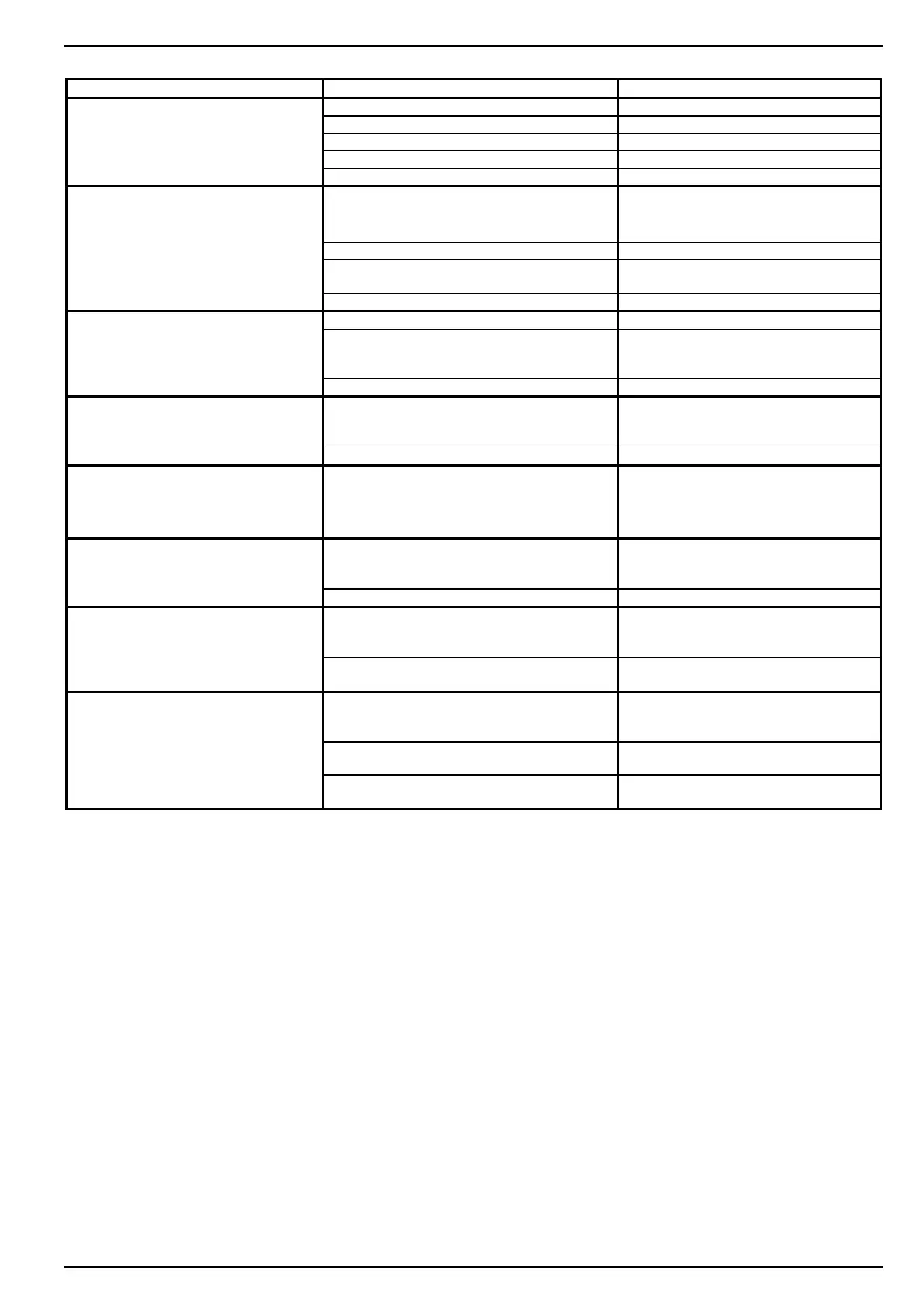

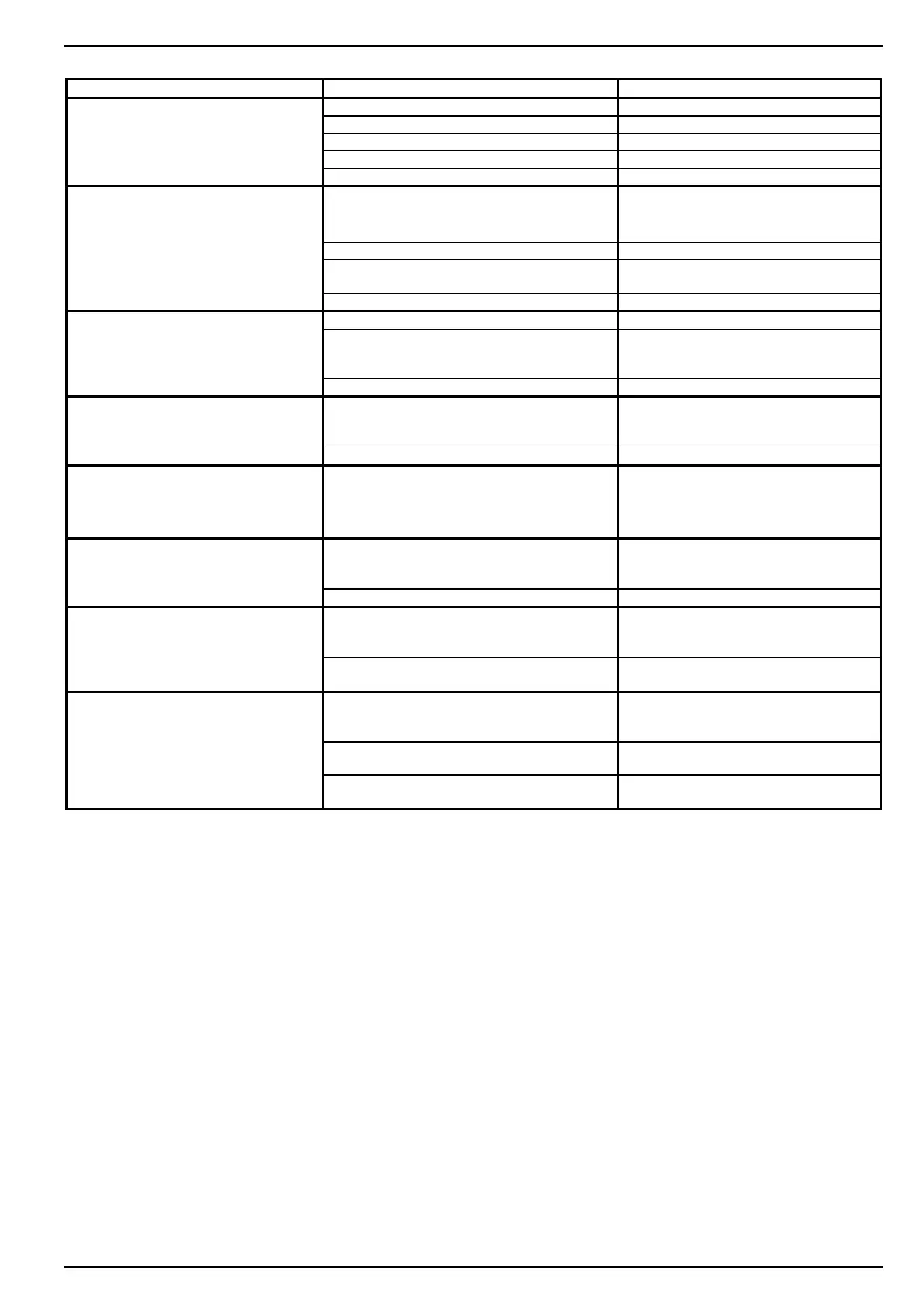

Table 1 - Troubleshooting.

FAULT CAUSE REMEDY

The control unit does not switch on. Inadequate or no mains voltage. Check.

Control unit led ON keeps off. Either connectors or cables disconnected. Check.

Fuse FU1 blown. Replace it.

Faulty main switch. Check and eventually replace it.

Faulty control unit. Replace it.

The welder does not carry out the

welding. Control unit START led does

not light by pressing foot-control.

The foot-control does not activate the start

cycle micro-switch. Faulty set up of the force

adjusting screw

Check

Either connectors or cables disconnected. Check.

The start of cycle microswitch placed on the

foot-control does not work properly.

Check and eventually replace it.

Faulty control unit. Replace it.

The welder does not carry out the MODE selector set to NO WELD. Set to TIMER.

welding. Control unit START led light

by pressing foot-control. The

CURRENT light is off during all the

Protection thermostat activated. The control

unit THERMOSTAT led lights.

Check that water circulates in the

required quantity. Check for a too high

working rate.

welding cycle. Faulty control unit. Replace it.

The welder unit carries out the welding

cycle without current circulation. The

control unit CURRENT led lights.

Faulty contact in the secondary circuit Check and tighten all the secondary

connections. Do not forget the electrode

and electrode-holder connection.

Faulty control unit. Replace it.

During the welding process, the

machine stops without ending the

welding time.

Too high voltage drop. Check that, when working, voltage drop

is lower than 25%. On the contrary,

check that supply cables section is

adequate to their length.

Spots or electrodes overheating. Insufficient cooling. Check that water circulates in the

required quantity and at a low

temperature.

Too high welding current or welding time. Reduce them.

Electrodes reduced life. Insufficient cooling. Check that water circulates in the

required quantity and at a low

temperature.

Under-seized electrode in comparison with

the work to carry out

Check both seize and contact diameter.

Secondary connections reduced life. Insufficient cooling. Check that water circulates in the

required quantity and at a low

temperature.

Heating caused by an inadequate clamping of

the flexible connection.

Carefully tighten the clamping screws.

Too high heating caused by a too high

welding rate

Reduce it.

Loading...

Loading...