P2012

AIRCRAFT MAINTENANCE MANUAL

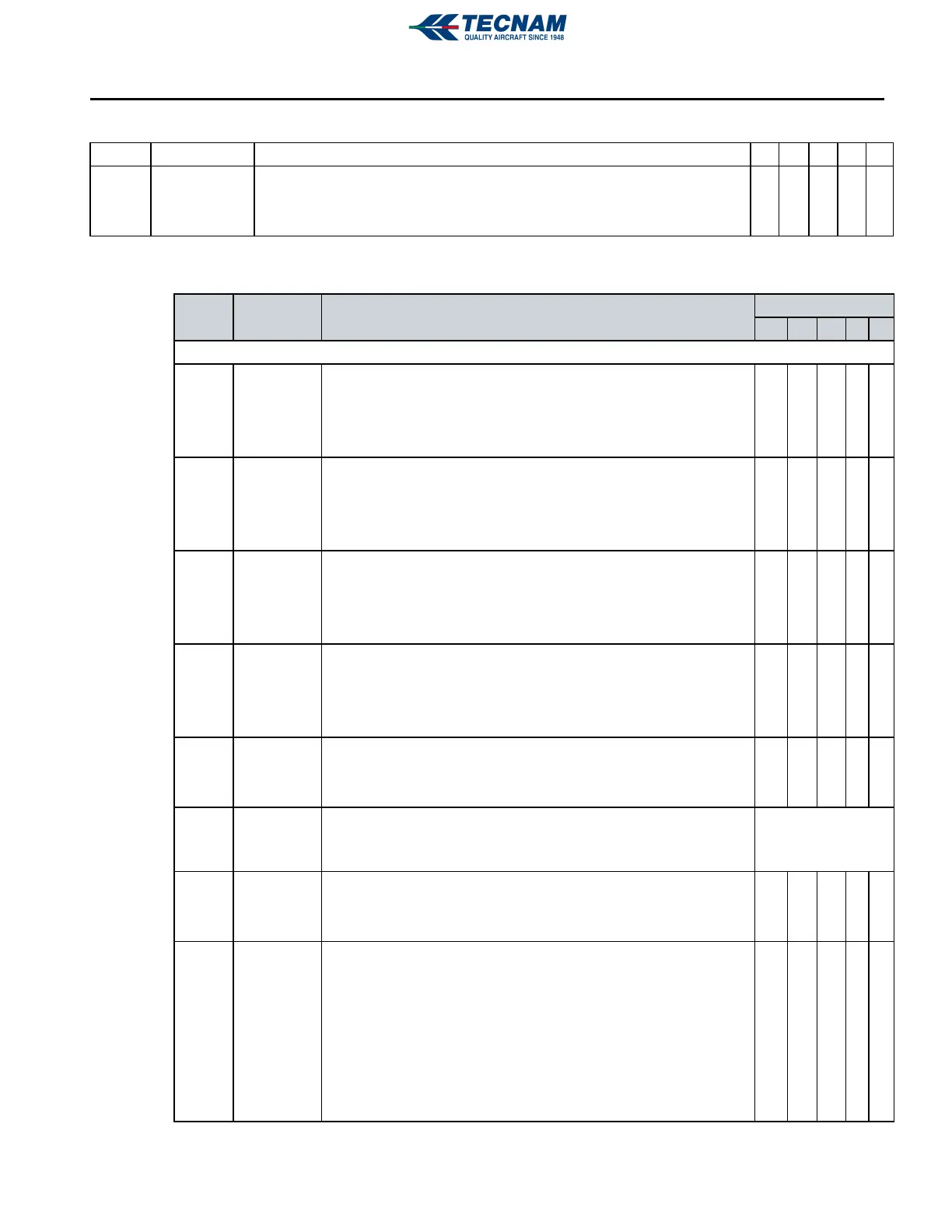

Protection Operate fire detector push-to-test.

26-00 Fire

Protection

Inspect portable fire extinguishers, weigh and follow service instruction

written on the bottle (if necessary replace). Inspect for condition and

ease of access. weight according the CMM latest issue.

X

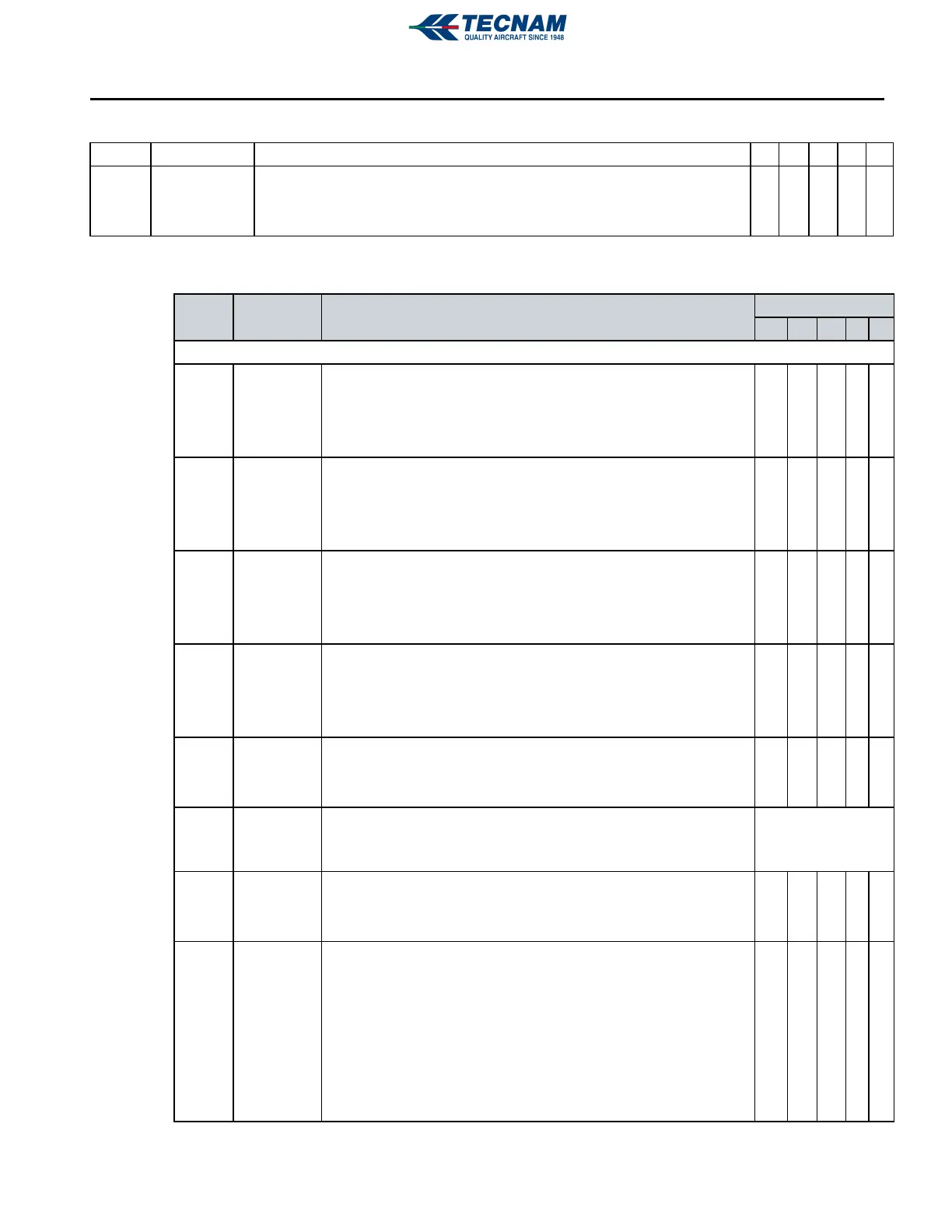

ATA Aircraft

Zone

Maintenance Task Frequency

A B C D E

POWER PLANT

71-00 Powerplant Engine mounts isolators: check for integrity, and bolts proper

torque and torque seal.

(*)

71-00 Powerplant Check engine mount truss attachments for proper torque

value (top attachments, clevis-to-bulkhead and clevis-to-

truss).

(*)

71-00 Powerplant Visually inspect engine mount truss assembly for bent,

corrosion, cracked or buckled tubes and engine mount

isolators attachments. Check engine mount bolt.

(*)

71-00 Powerplant Engine electrical harness and equipment: check for condition

and security of installation.

(*)

71-00 Powerplant Visually inspect air induction system for integrity. Check the

alternate static air source valve for integrity and correct

operation.

X

71-00 Powerplant Inspect induction system filter according to Brackett Aero

Filters manufacturer manual. Verify expiry date.

Ref. CMM (see

Bracket Aero Filters

Doc No I-194)

71-00 Powerplant Check engine and propeller control cables (bowden) full

travel and correct operation. Check for restricted movement,

interference or unusual freeplay. Check friction for operation.

X

71-00 Powerplant Inspect for fuel, oil liquid leakages; inspect hoses, fittings,

clamps and all other components of the systems for cracks,

holes, dents. bulges and other signs of damage that might

restrict The fluid flow or cause a leakage. All lines must be

inspected to ensure that they are properly supported and are

not rubbing against a structure. Fittings should be checked

for signs of improper installation. Overtorquing, excessive

X

05-20-00

Page 11

5

th

Edition - Rev. 0

2022, Jan 14

Loading...

Loading...