5.3. Precoating of the filter cartridges

For a longer service life of the filter cartridges, the new filter cartridges can be pretreated with filter aid

(e.g. precoat). However, this is not necessary when using nano filter cartridges.

Please read and refer to "Precoating new filter cartridges" in the chapter "Maintenance". There

you can also find a description of the operating method of the precoat.

5.4. Connecting the compressed air supply

The compressed air must be dry and oil-free.

According to ISO 8573-1:2010 the compressed air quality must at least meet: [7:4:4]

➔ Partikle size: <40µm

➔ Pressure dew point: <= +3°C

➔ Oil content: <=5mg/m³

5.4.1. Compressed air supply for the cleaning of the filter cartridges

The filter cartridges of the system are automatically cleaned. Cleaning is carried out pneumatically via a

built-in compressed air tank.

Without compressed air supply the filter cartridges will become dirty very quickly.

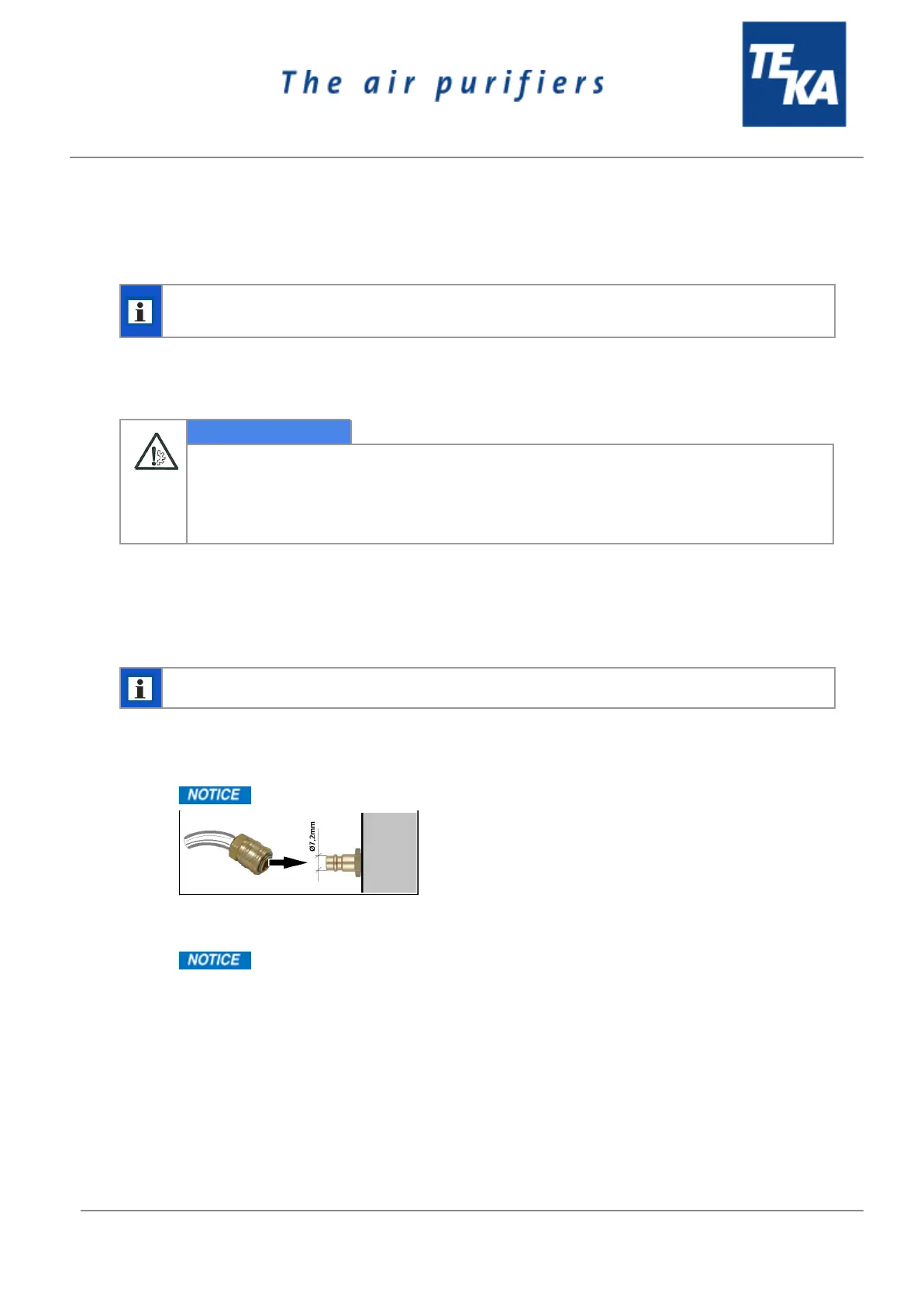

● The external compressed air supply must be assured with an approved compressed air hose.

For the connection to the device, the compressed air hose must be equipped with a quick

coupling for an insert sleeve DN 7.2.

The compressed air must be dry and oil-free.

● The operating pressure of the compressed air supply must be a minimum of 3 bars and

maximum of 4 bars.

In case of the pressure being too low, the compressed air tank does not reach

quickly enough the operating pressure for the following cleaning. There is a risk of

material damage when the pressure is too high.

● Connect the compressed air hose to the insert sleeve (see chapter 2.1).

BA_LFE-101-201-301_220114_EN

Loading...

Loading...