- 15 -

GB

SPLITSPLIT

SPLITSPLIT

SPLIT 7000

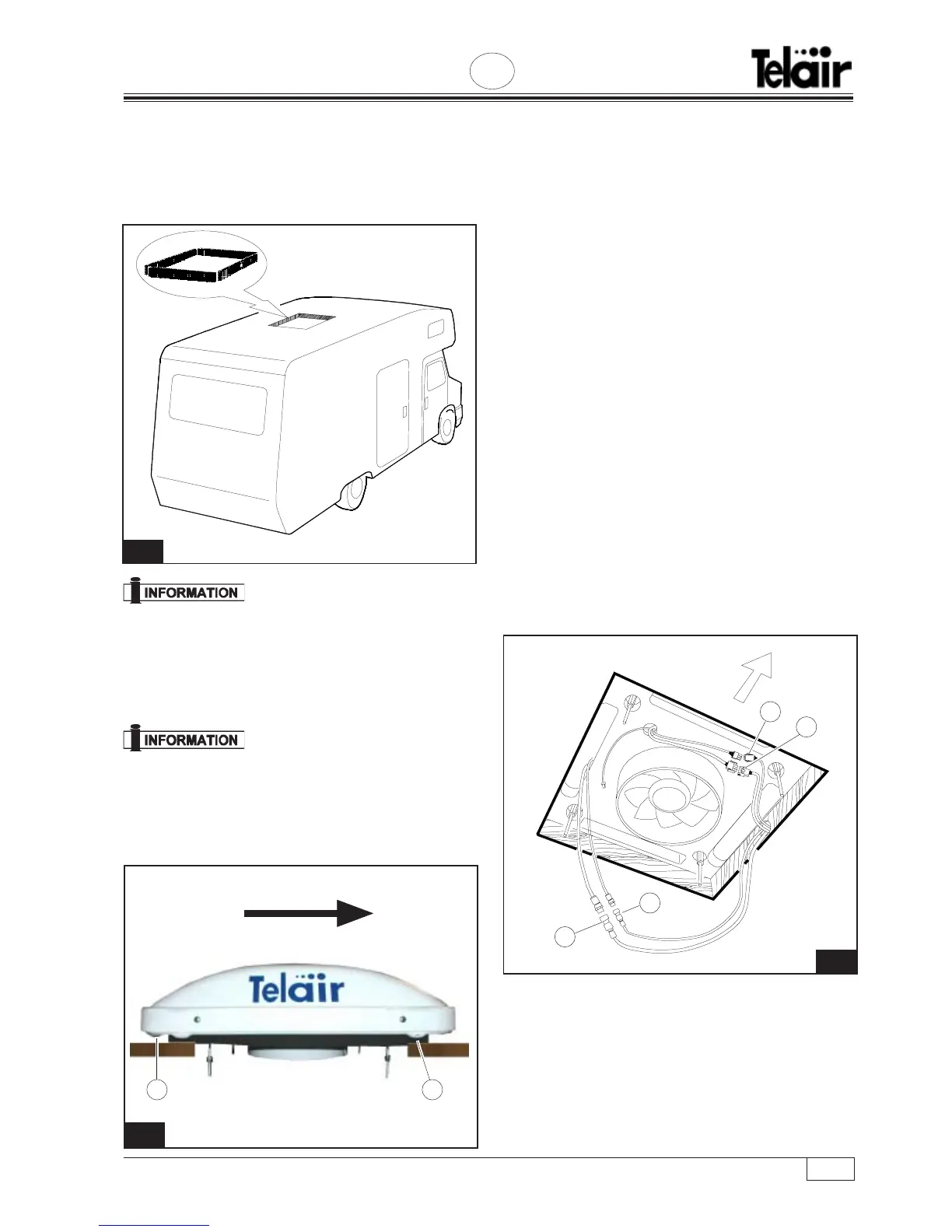

direction of the vehicle, while the rear holes Fig. 13

Ref. (2) face the rear of the vehicle.

The arrow on Fig. 13 shows the driving direction of

the vehicle.

prevent any condensate forming inside the

vehicle while the equipment is working.

Connect the two flexible hoses by screwing down

the two quick locks with their respective wrenches.

Connect the smaller hose (6 mm) Fig. 14 Ref. (3)

first, using two 19mm wrenches, and then the larger

hose (10 mm) Fig. 14 Ref. (4) with one 22mm

wrench and another 24mm wrench. Wrap the large

pipe and the coupling in the condensate-proofing

material supplied.

Introduce the aluminium air conveyor Fig. 15 Ref.

(1) into the plastic tube of the evaporator and push

it in until the 2 fastening brackets Fig. 15 Ref. (2)

are level to the roof of the vehicle, ensuring that the

4 fastening bolts pass through the fixing holes Fig.

15 Ref. (3).

Screw down the 4 nuts Fig. 15 Ref. (4) and tighten

until the thickness of the rubber liner is reduced by

1/3.

Note: The air conveyor has been designed to be

installed on vehicles with a roof thickness between

12

13

2 1

FRONT

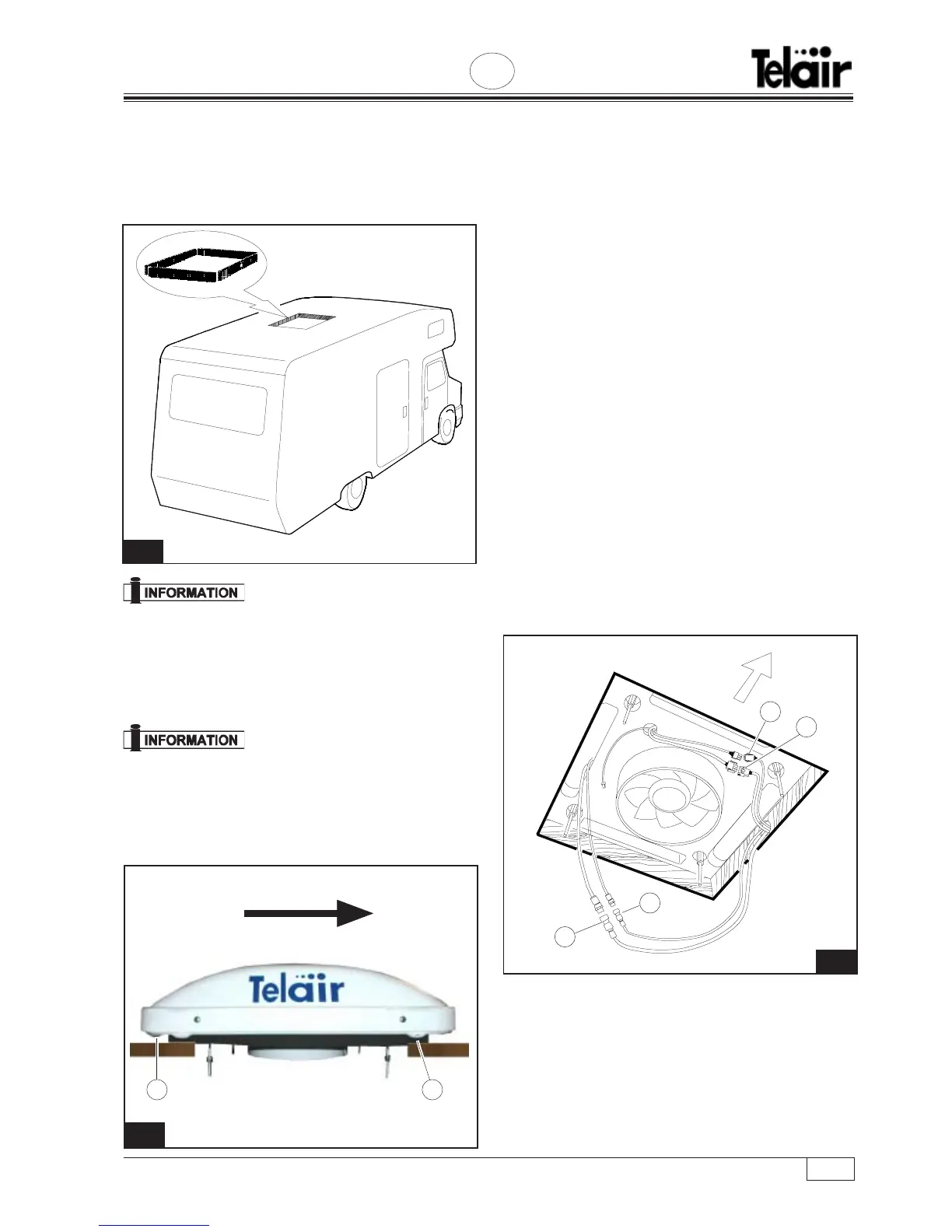

Place the outside unit on the

roof as shown on the figure and centre it

over the 40 x 40 hole.

Connect both cables coming from the condenser

unit to the relevant cables Fig. 14 Ref. (1) and (2).

Cover the pipe with larger-

cross section (10mm) outgoing cable with the

condensate-proofing material supplied, to

14

2

1

FRONT

3

4

Loading...

Loading...