TELEDYNE

ANALYTICAL INSTRUMENTS

OPERATING INSTRUCTIONS

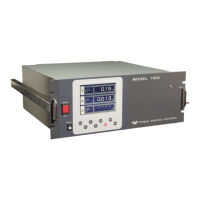

Series Model 7500

Infrared Gas Analyzer

DANGER

HIGHLY TOXIC AND OR FLAMMABLE LIQUIDS OR GASES MAY BE PRESENT IN THIS

MONITORING SYSTEM.

PERSONAL PROTECTIVE EQUIPMENT MAY BE REQUIRED WHEN SERVICING THIS SYSTEM.

HAZARDOUS VOLTAGES EXIST ON CERTAIN COMPONENTS INTERNALLY WHICH MAY PERSIST

FOR A TIME EVEN AFTER THE POWER IS TURNED OFF AND DISCONNECTED.

ONLY AUTHORIZED PERSONNEL SHOULD CONDUCT MAINTENANCE AND/OR SERVICING.

BEFORE CONDUCTING ANY MAINTENANCE OR SERVICING CONSULT WITH AUTHORIZED

SUPERVISOR/MANAGER.

P/N

07/07/11