- 11 -

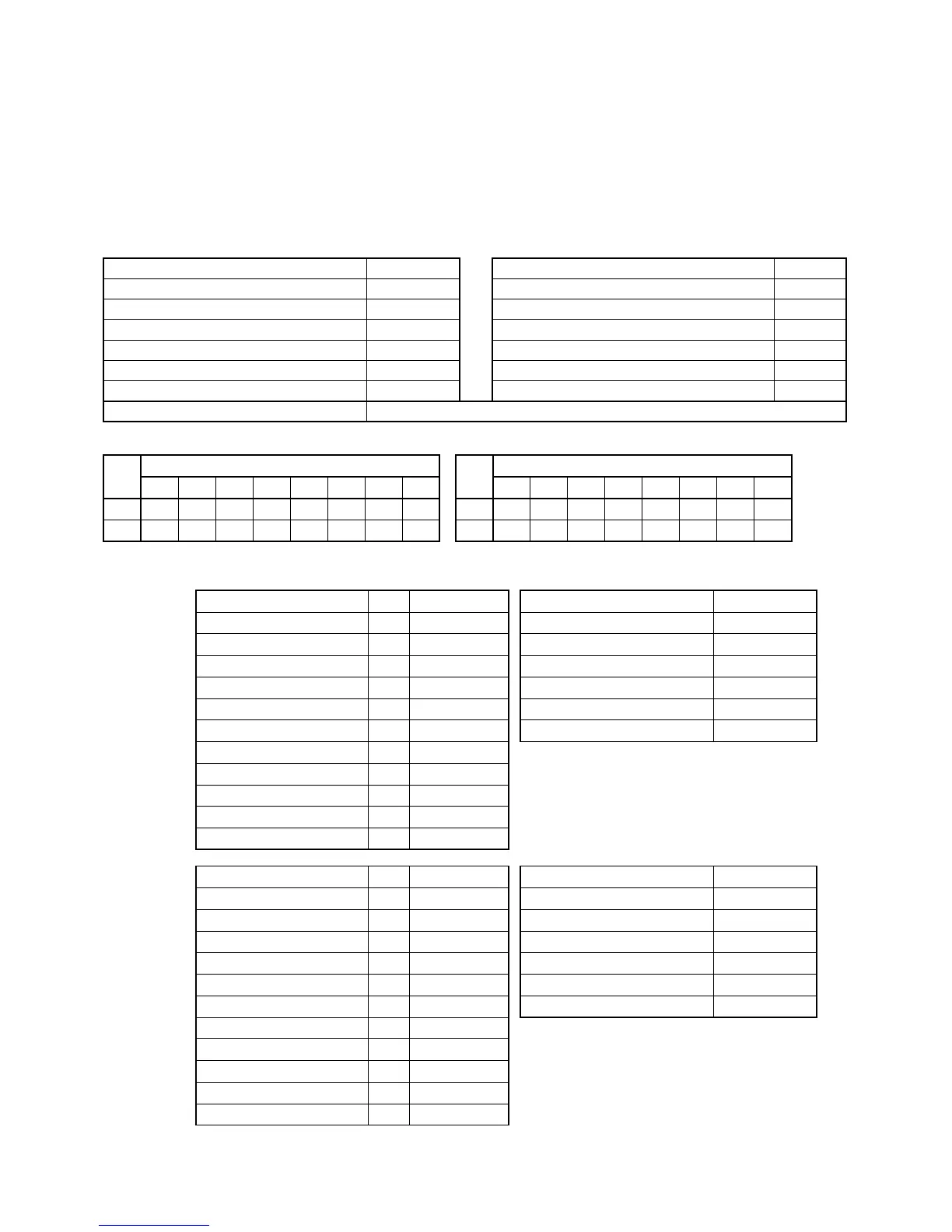

INSTALLER TO COMPLETE

Commissioning Check List

Site Name/address: ..........................................................................................................................................................................

Installing Company ...................................................................................................... Date: ..........................................................

Serviceman: ............................................................................................................... Tel: ............................................................

Model: ......................................................................... Serial No: ................................................ Unit Site Ref: .............................

Units is installed level? Y / N Return air lter tted? Y / N

Mounting springs adjusted & balanced? Y / N Is air ow set and balanced? Y / N

Drain trap tted (if applicable)? Y / N Are UC8 controller parameters set? Y / N

Water drains tested okay? Y / N External electrical isolator tted? Y / N

Water connections checked? Y / N Refrigerant leak cheaked? Y / N

Do units have adequate safe access? Y / N Certicate Of Compliance issued? Y / N

All electrical terminals are tight? Y / N Has client had controls demonstrated? Y / N

Thermostat type: BMS / SAT-3 / TZT-100 / Other? (name):

Mark UC8 dip switch positions with an 'X'

SW1 SW2

1 2 3 4 5 6 7 8

9 (1) 10 (2) 11 (3) 12 (4) 13 (5) 14 (6) 15 (7) 16 (8)

On On

Off Off

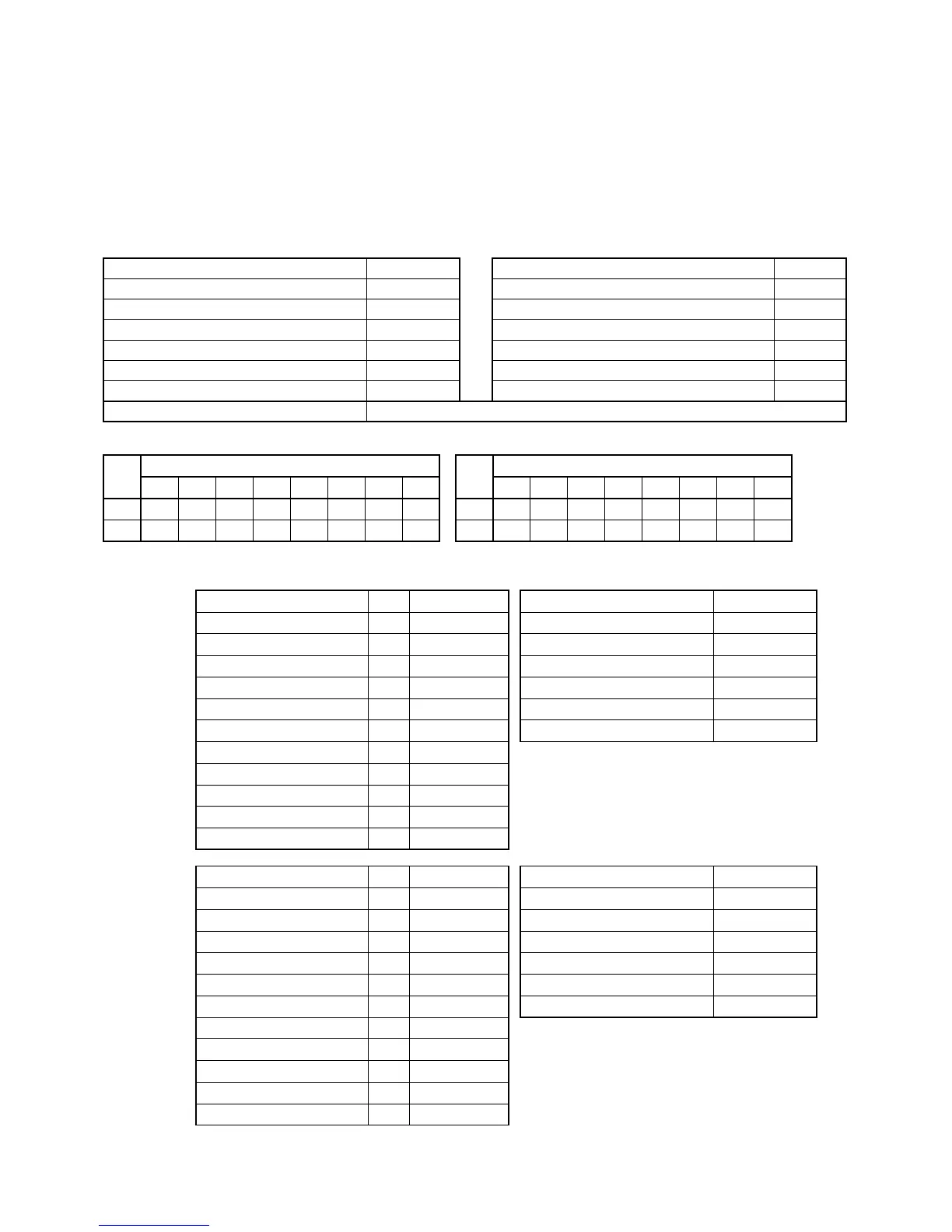

Record the following UC8 monitored conditions, at least 10 minutes after compressor starts, using push button SW3

(repeat to scroll through list):

Cool Cycle:

Low Pressure: SLP kPa Return air temperature: °C

Evap temperature: Et °C Supply air temperature: °C

Suction Line temperature: SLt °C Entering Water temperature: °C

Suction Superheat: SSH K Leaving Water temperature: °C

Discharge Line Pressure: dLP kPa Compressor amps: A

Condensing temperature: Ct °C Total amps: A

Discharge Line temperature: dLt °C Input voltage: A

Discharge Superheat: dSH K

De-ice Sensor temperature: ICEt °C

Required Capacity: CAP %

Expansion Valve 1: EE1 %

Expansion Valve 2: EE2 %

Heat Cycle:

Low Pressure: SLP kPa Return air temperature: °C

Evaporating temperature: Et °C Supply air temperature: °C

Suction Line temperature: SLt °C Entering Water temperature: °C

Suction Superheat: SSH K Leaving Water temperature: °C

Discharge Line Pressure: dLP kPa Compressor amps: A

Condensing temperature: Ct °C Total amps: A

Discharge Line temperature: dLt °C Input voltage: A

Discharge Superheat: dSH K

De-ice Sensor temperature: ICEt °C

Required Capacity: CAP %

Expansion Valve 1: EE1 %

Expansion Valve 2: EE2 %

Water temperature difference should be: Cooling: 5–7°C, Heating 3–5°C.

Loading...

Loading...