TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4

Page 11

GN2 Purge System

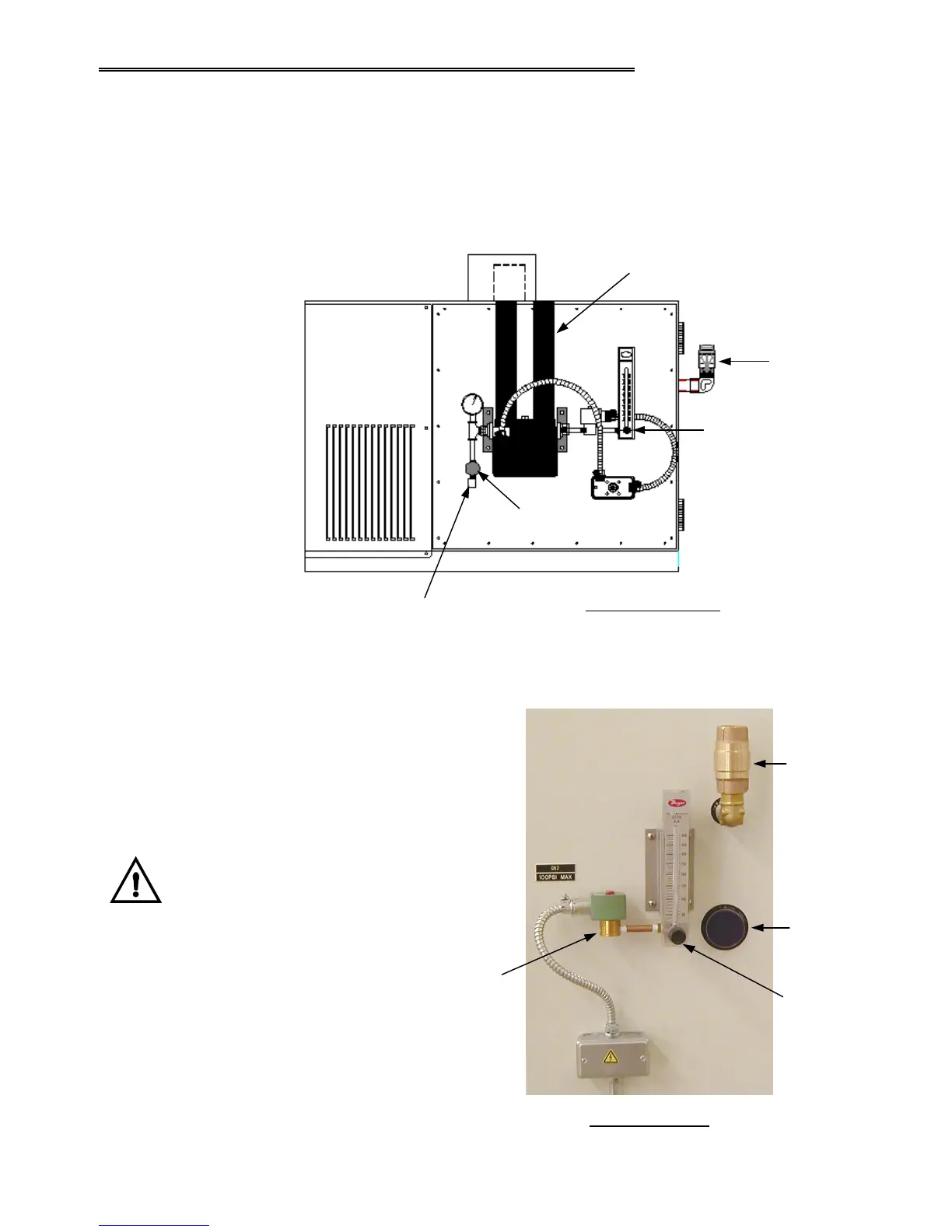

5.3 Air Supply Connection (For Optional Equipment)

Your chamber will require a compressed air supply for the Dry Air Purge System option. The system is

mounted on the back side of the chamber. The supply should be clean and dry, and range from 80 PSIG

min. to 100 PSIG max. The connection type is ¼” FPT. Make sure the connection is secure. Reference the

corresponding “Option” section in this manual, or your chamber specifications for more details.

Flow Adjustments:

Adjust the flow

adjustment valve at the

supply connection to

maintain 100 PSIG max.

Adjust the flowmeter

metering valve to

approximately 300 cubic

feet per hour.

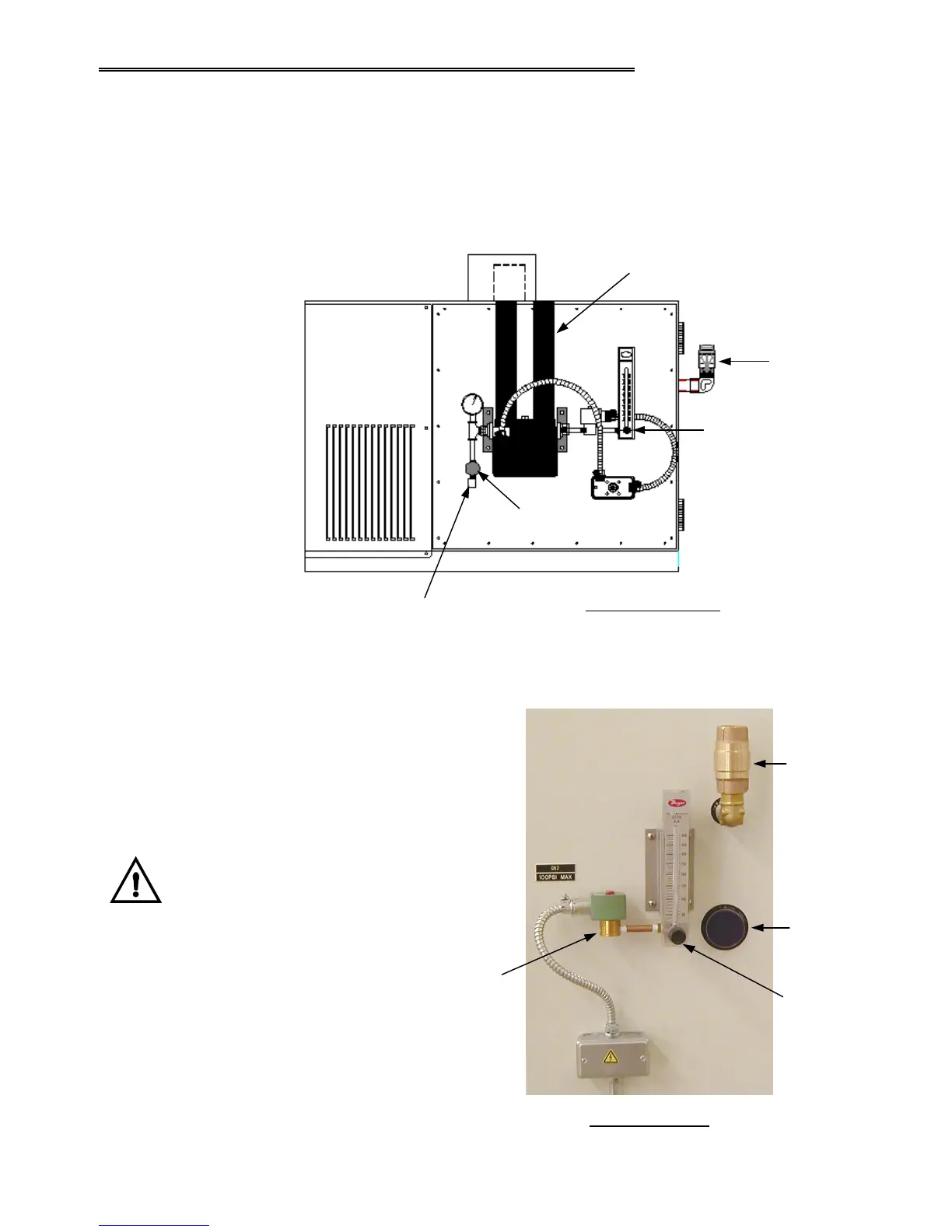

5.4 GN2 Connection (For Optional Equipment)

Your chamber will require a supply of gaseous nitrogen

for the GN2 Purge System option. The supply may range

up to 100 PSIG maximum. The connection is type 1/8”

NPT. Make sure the connection is secure. Reference the

corresponding “Option” section in this manual and your

chamber specifications for more details.

Flow Adjustment:

Adjust the metering valve to maintain approximately 300

cubic feet per hour.

Vent Port

Checkvalve

Chamber

ccess Port

Metering

Valve

GN2 Supply

Connection

1/8” NPT

Warning! Gaseous nitrogen displaces

oxygen. Make sure the area surrounding the

chamber is well ventilated to dilute the gas

vented from the chamber vent port

checkvalve.

Dry Air Purge System

Metering Valve

Flow Adjustment Valve

Twin Tower

Heatless Dryer

Vent Port

Checkvalve

Back Side o

Chamber (TJR)

Compressed Air Supply

Connection Input 1/4” FPT

Loading...

Loading...