TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4

Page 20

Heating of the chamber is accomplished with the use of open air low mass nichrome wire heating elements.

These elements have low thermal lag and provide rapid response to the controller's demands. The elements

are mounted in the plenum conditioning section. This isolates them from the workspace and prevents direct

radiation to the product. The heater bank is rated 500 Watts, consisting of two 250 Watt elements.

Heater Control:

The heaters are controlled by a time proportioned output from the main controller. This output triggers a triac

to conduct and provide power to the elements.

Note: The Boost Heat option may be provided to increase the rate of heating. Reference the “Boost Heat”

option section for details.

9.1 Overview

A thermal cutoff (labeled as Heat Limiter HL) is provided to protect the chamber against overtemperature

conditions. This is an axial leaded one-shot protection device, which is connected in-line with the mains

power supply Neutral Line, directly to the heater rack. The thermal cutoff will permanently open and remove

power from the heater elements when the surrounding air temperature reaches 240°C. Once the thermal

cutoff opens, it must be replaced.

Note: The thermal cutoff is not used when the Boost Heat option is employed. This option uses a Watlow

147 Limit Controller for overtemperature protection. Reference the “Boost Heat” option section for details.

8.0 HEATING DESCRIPTION

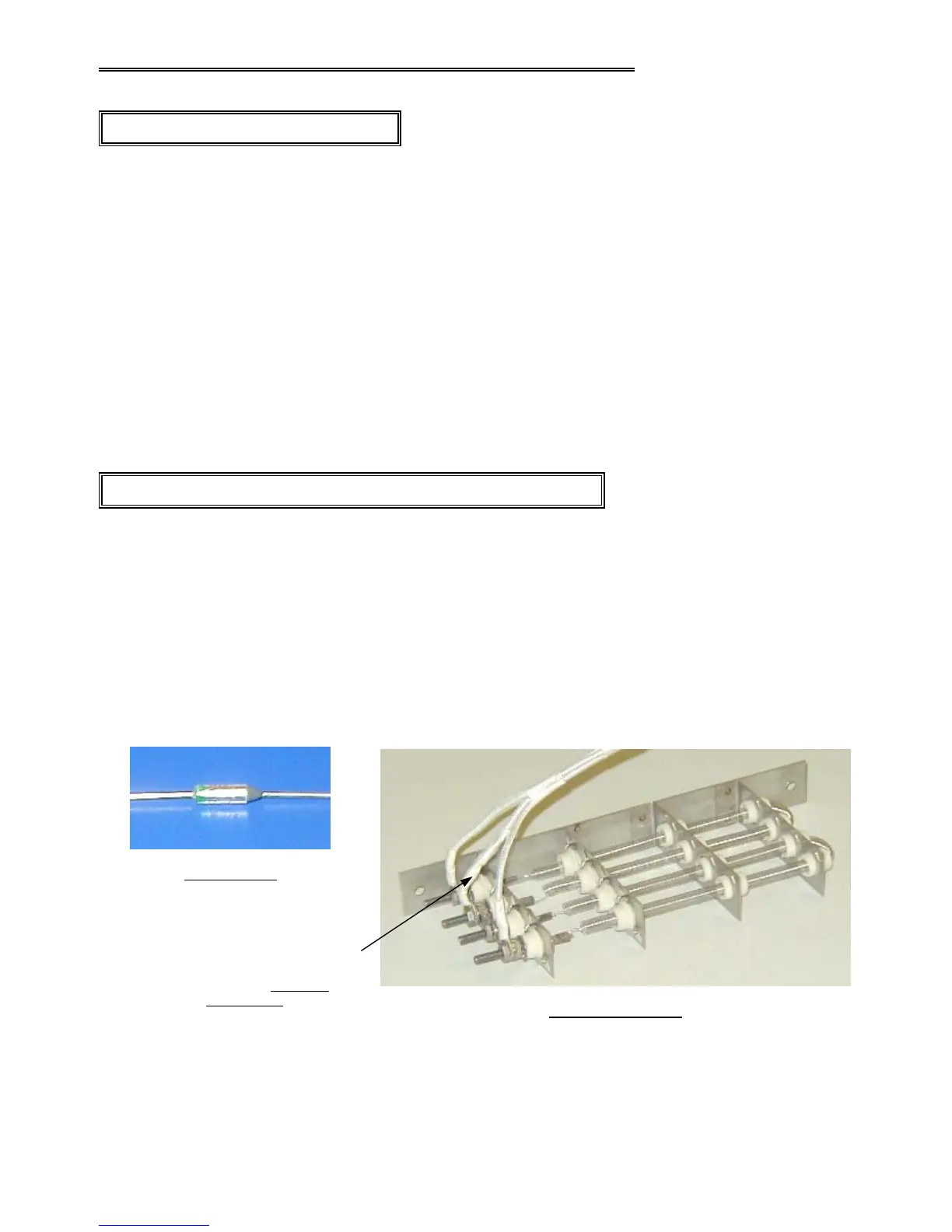

Heater Element Rack

Thermal Cutoff is installed

in the Neutral Line, and is

wrapped in glass cloth

electrical tape.

9.0 CHAMBER OVERTEMPERATURE PROTECTION

Thermal Cutoff

Loading...

Loading...