TENNEY ENVIRONMENTAL

Tenney Junior Test Chambers: Models TJR and TUJR, W942, or WF4

Page 12

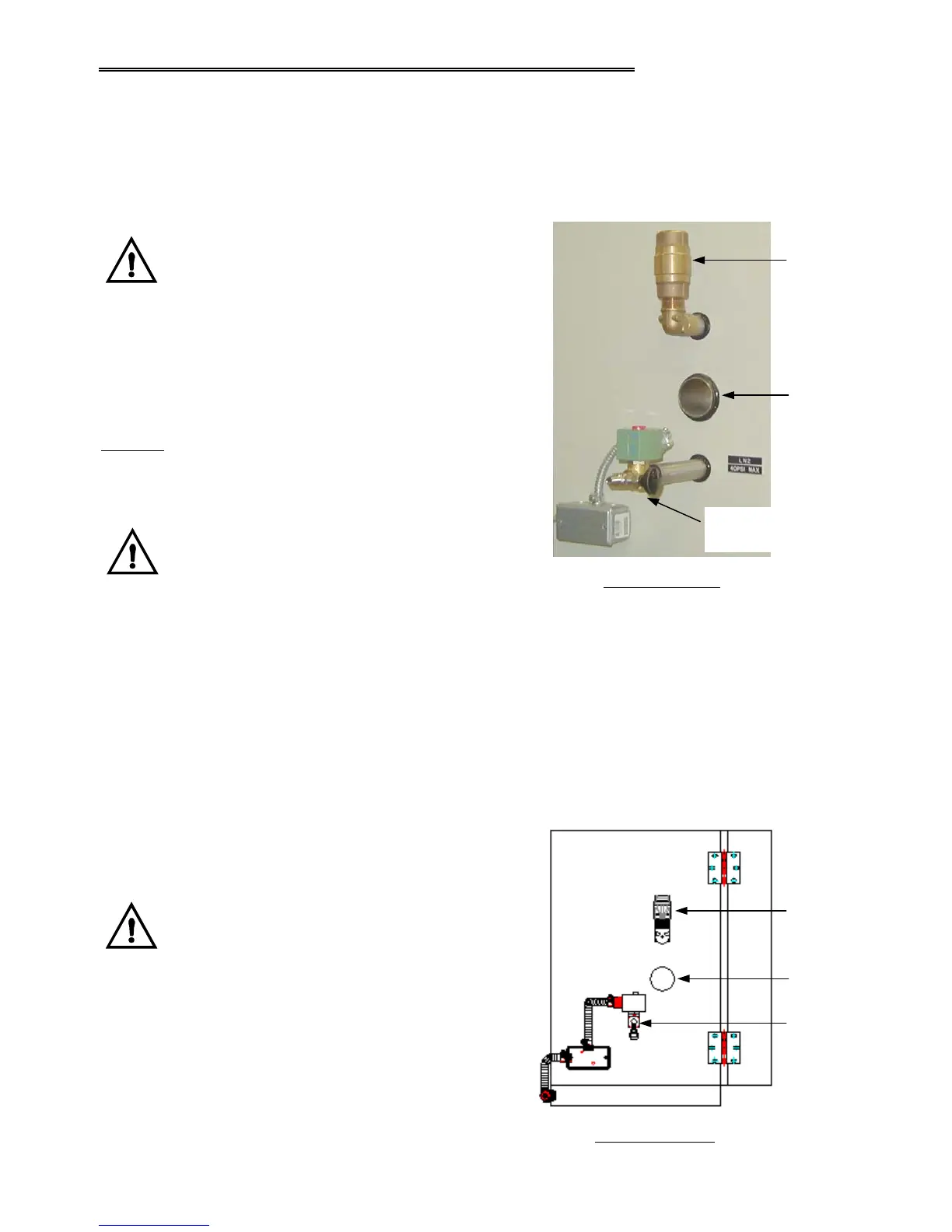

5.5 LN2 Connection (For Optional Equipment)

Your chamber will require a supply of liquid nitrogen for the LN2 Boost Cooling option. The supply may range

up to 40 PSIG maximum. The connection is type 1/8” NPT. Make sure the connection is secure. Reference

the corresponding “Option” section in this manual and your chamber specifications for more details.

Warning! Gaseous nitrogen resulting from

vaporized LN2 displaces oxygen. Make sure the

area surrounding the chamber is well ventilated to

dilute the gas vented from the chamber vent port

checkvalve!

LN2 Flow Adjustment:

LN2 systems are provided with a manually set flow adjusting

valve, which permits the adjustment of nitrogen flow to avoid

incomplete evaporation at varying LN2 supply pressures. As

the chamber cools to the extreme cold temperature limit,

complete evaporation of liquid nitrogen may not occur if the

supply pressure is allowed to drop. Incomplete evaporation

will cause droplets of liquid to fall to the chamber floor and

cause puddling.

Do not allow liquid nitrogen to contact the door

gasket. Exposure to LN2 will damage the gasket

and violate the seal.

A setting of 4 turns open of the valve generally provides good

performance at a supply pressure of 20 to 25 PSIG. This valve may be readjusted as necessary to

accommodate the supply pressure at the end use point.

Note: Your equipment configuration may be slightly different from what is shown.

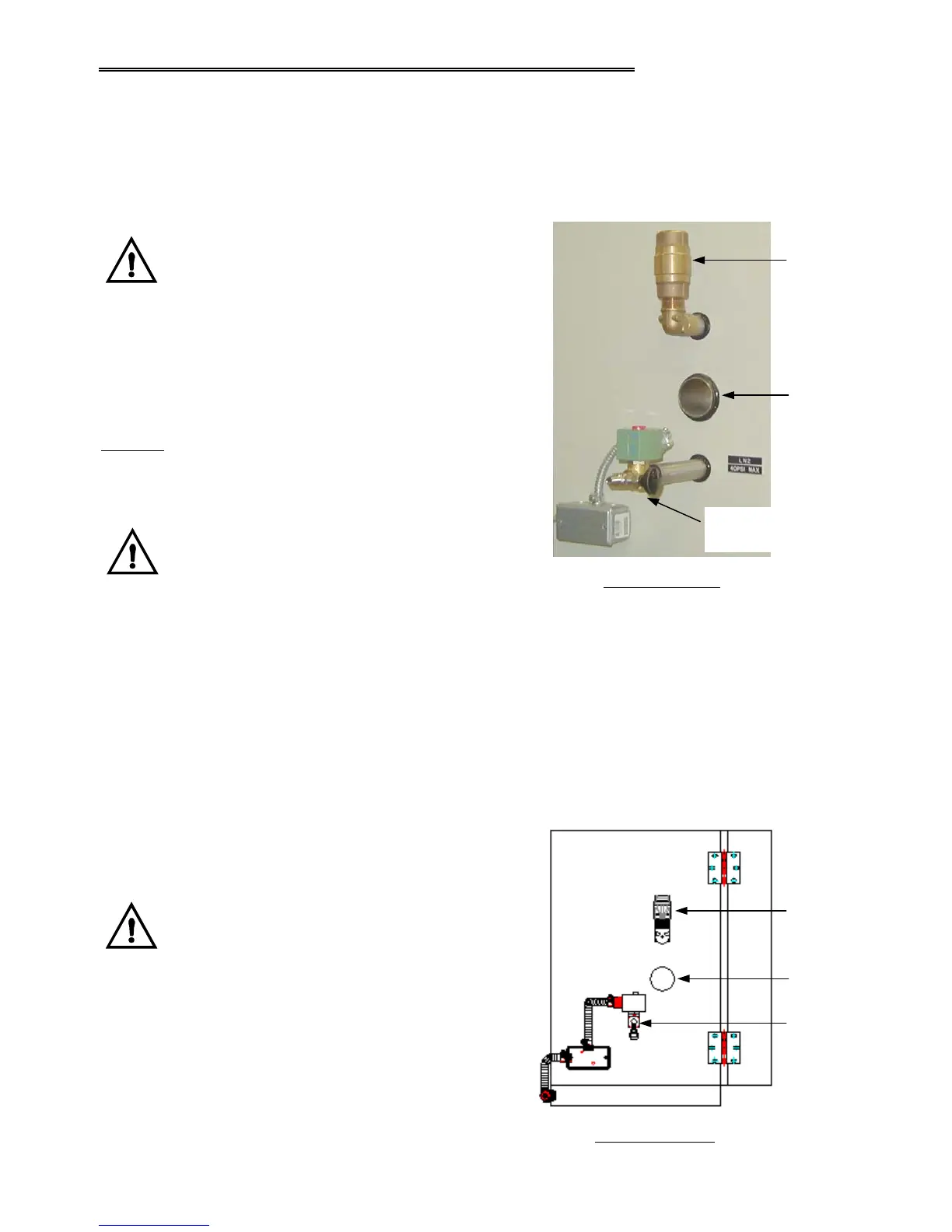

5.6 CO2 Connection (For Optional Equipment)

Your chamber will require a supply of liquid carbon dioxide for the CO2 Boost Cooling option. The supply

may range up to 1000 PSIG. The connection is type 1/8” NPT. Make sure the connection is secure.

Reference the corresponding “Option” section in this

manual and your chamber specifications for more details.

Warning! Carbon Dioxide gas displaces

oxygen. Make sure the area surrounding the

chamber is well ventilated to dilute the gas

vented from the chamber vent port checkvalve!

Note: There is no flow adjustment for the CO2 supply. A

fixed orifice on the injection port inside the chamber

regulates the supply.

Note: Your equipment configuration may be slightly

different from what is shown.

CO2 Boost Cooling

CO2 Supply

Connection

Vent Port

Checkvalve

Chamber

ccess Port

LN2 Boost Cooling

Chamber

ccess Port

Vent Port

Checkvalve

LN2 Supply Connection &

Flow Adjustment Valve

Loading...

Loading...